Difference between revisions of "Attachment of Single Contact Parts"

(→Resistance Brazing) |

Doduco Admin (talk | contribs) |

||

| (83 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

| − | The following segments give an overview of the usually applied attachment | + | The following segments give an overview of the usually applied attachment technologies for contact parts to carrier components. They include mechanical as well as brazing and welding methods used for electrical contact assemblies. |

| − | technologies for contact parts to carrier components. They include mechanical | ||

| − | as well as brazing and welding methods used for electrical contact assemblies. | ||

| − | == Mechanical Attachment Processes== | + | === Mechanical Attachment Processes=== |

| − | Rivet staking and the insertion and forming of wire segments into pre-stamped | + | Rivet staking and the insertion and forming of wire segments into pre-stamped carrier parts or strips with punched holes are the most commonly used methods for the mechanical attachment of contact materials. |

| − | carrier parts or strips with punched holes are the most commonly used methods | ||

| − | for the mechanical attachment of contact materials. | ||

| − | Riveting (or staking) for smaller volumes of assemblies is mostly done on | + | Riveting (or staking) for smaller volumes of assemblies is mostly done on mechanical, pneumatic or magnetically operated presses. For larger volumes |

| − | mechanical, pneumatic or magnetically operated presses. For larger volumes | + | the staking process is integrated into a progressive die for fully automated assembly. Rivets are fed in the correct orientation through special feeding tracks into the staking station of the tool. To ensure a mechanically secure attachment, the rivet shank must be dimensioned correctly. As a general rule, the shank length of the rivet should be about 1/3 longer than the thickness of the carrier material. |

| − | the staking process is integrated into a progressive die for fully automated | + | For switch-over contacts part of the rivet shank is formed into the secondary rivet head. To minimize deformation of the contact blade carriers, especially thin ones, this head forming is often performed by orbital riveting. |

| − | assembly. Rivets are fed in the correct orientation through special feeding | ||

| − | tracks into the staking station of the tool. To ensure a mechanically secure | ||

| − | attachment the rivet shank must be dimensioned correctly. As a general rule the | ||

| − | shank length of the rivet should be about 1/3 longer than the thickness of the | ||

| − | carrier material. | ||

| − | For switch-over contacts part of the rivet shank is formed into the secondary | ||

| − | rivet head. To minimize deformation of the contact blade carriers, especially thin | ||

| − | ones, this head forming is often performed by orbital riveting. | ||

| − | The insertion and forming of wire segments can be easily integrated into stamp | + | The insertion and forming of wire segments can be easily integrated into stamp and bending multi-slide tooling (<xr id="fig:Direct_press_insertion_of_wire_segments"/><!--(Fig. 3.7)-->). Compared to the use of composite rivets this process uses more precious contact material but for silver based contact materials these costs are often offset by higher and more efficient manufacturing speeds. For the more brittle Ag/SnO<sub>2</sub> materials however, close attention must be paid to the danger of crack formation. |

| − | and bending multi-slide tooling | ||

| − | rivets this process uses more precious contact material but for silver based | ||

| − | contact materials these costs | ||

| − | manufacturing speeds. For the more brittle Ag/SnO<sub>2</sub> materials however close | ||

| − | attention must be paid to the danger of crack formation. | ||

| − | + | <figure id="fig:Direct_press_insertion_of_wire_segments"> | |

| + | [[File:Direct press-insertion of wire segments.jpg|right|thumb|Figure 1: Direct press-insertion of wire segments]] | ||

| + | </figure> | ||

| − | ==Brazing Processes== | + | ===Brazing Processes=== |

| − | Brazing is a thermal process for the metallurgical bonding of metallic materials in | + | Brazing is a thermal process for the metallurgical bonding of metallic materials in which a third metal component (brazing alloy or solder) is added. In addition a flux or processing in a protective atmosphere is applied to eliminate oxidation of the non-precious carrier. The melting range of the brazing alloy starts at the beginning of the melting (solidus temperature) all the way to complete liquid phase (liquidus temperature). This range always is below the melting points of the two materials to be joined. During the brazing process with solubility of the |

| − | which a third metal component (brazing alloy or solder) is added. In addition a | + | materials in each other, diffusion processes are thermally activated by which elements of the base material diffuse into the brazing alloy and elements of the braze alloy diffuse into brazing alloy. This increases the bond strength and therefore the mechanical stability of the brazed joint. |

| − | flux or processing in a protective atmosphere is applied to eliminate oxidation of | ||

| − | the non-precious carrier. The melting range of the brazing alloy starts at the | ||

| − | beginning of the melting (solidus temperature) all the way to complete liquid | ||

| − | phase (liquidus temperature). This range always is below the melting points of | ||

| − | the two materials to be joined. During the brazing process with solubility of the | ||

| − | materials in each other diffusion processes are thermally activated by which | ||

| − | elements of the base material diffuse into the brazing alloy and elements of the | ||

| − | braze alloy diffuse into brazing alloy. This increases the bond strength and | ||

| − | therefore the mechanical stability of the brazed joint. | ||

| − | For attachment of contact parts to carrier base materials only brazing alloys (as | + | For attachment of contact parts to carrier base materials, only brazing alloys (as opposed to solders) are used. The reason is the higher softening temperature and melting point as well as higher mechanical strength and electrical conductivity of these alloys. The brazing alloys and fluxes used for electrical contact attachment are listed in [[Brazing Alloys and Fluxes|Brazing Alloys and Fluxes ]] in more detail. Following the most frequently used brazing methods are described. |

| − | opposed to solders) are used. The reason is the higher softening temperature | + | References to the bond quality are given according to the test methods described in [[Evaluation_of_Braze_or_Weld_Joints|Evaluation of Braze or Weld Joints ]] |

| − | and melting point as well as higher mechanical strength and electrical | ||

| − | conductivity of these alloys. The brazing alloys and fluxes used for electrical | ||

| − | contact attachment are listed in | ||

| − | frequently used brazing methods are described. | ||

| − | References to the bond quality are given according to the test methods | ||

| − | described in | ||

| − | === Flame (or Torch) Brazing=== | + | ==== Flame (or Torch) Brazing==== |

| − | The | + | The easiest way to produce braze joints, is the use of a gas torch fueled by a burning gas and air or oxygen containing gas mixes. For higher production volumes, partial automation is applied. The parts to be assembled are transported after adding the suitable amounts of brazing alloy and flux through a series of fixed gas burners on a turntable or belt driven brazing machine. To limit the amount of flux or gas inclusions, it is recommended to slightly move the contact tips back and forth (also known as puddeling) as soon as the brazing alloy is liquefied. The bonded area achieved in torch brazing is typically 65 – 90% of the contact foot print, depending on the size and geometry of the contact tip. |

| − | burning gas and air or oxygen containing gas mixes. For higher production | ||

| − | volumes partial automation is applied. The parts to be assembled are | ||

| − | transported after adding the suitable amounts of brazing alloy and flux through a | ||

| − | series of fixed gas burners on a turntable or belt driven brazing machine. | ||

| − | To limit the amount of flux or gas inclusions it is recommended to slightly move | ||

| − | the contact tips forth | ||

| − | brazing alloy is liquefied. The bonded area achieved in torch brazing is typically | ||

| − | 65 – 90% of the contact foot print depending on the size and geometry of the | ||

| − | contact tip. | ||

| − | ===Furnace Brazing=== | + | ====Furnace Brazing==== |

| − | Furnace brazing is usually defined as brazing in a protective atmosphere or in | + | Furnace brazing is usually defined as brazing in a protective atmosphere or in vacuum. Both processes do not require the use of fluxes. |

| − | vacuum. Both processes do not require the use of fluxes. | ||

| − | The protective atmosphere brazing is conducted in batch operation in either | + | The protective atmosphere brazing is conducted in batch operation in either muffle or pot furnaces or as a continuous process in belt furnaces, using a reducing atmosphere of pure hydrogen (H<sub>2</sub>) or dissociated ammonia (H<sub>2</sub>,N<sub>2</sub>). |

| − | muffle or pot furnaces or as a continuous process in belt furnaces using a | ||

| − | reducing atmosphere of pure hydrogen (H<sub>2</sub>) or dissociated ammonia (H<sub>2</sub>,N<sub>2</sub>). | ||

| − | A vacuum is a very efficient protective environment for brazing but using vacuum | + | A vacuum is a very efficient protective environment for brazing but using vacuum furnaces is more complicated and rather inefficient. Therefore this process is only used for materials and assemblies that are sensitive to oxygen, nitrogen, or hydrogen impurities. Not suitable for vacuum brazing are materials which contain components with a high vapor pressure. |

| − | furnaces is more complicated and rather inefficient. Therefore this process is | ||

| − | only used for materials and assemblies that are sensitive to oxygen, nitrogen, or | ||

| − | hydrogen impurities. Not suitable for vacuum brazing are materials which | ||

| − | contain components with a high vapor pressure. | ||

| − | Parts with oxygen containing copper supports should not be brazed in reducing | + | Parts with oxygen containing copper supports should not be brazed in reducing atmospheres because of their susceptibility to hydrogen embrittlement. Similarly contact tips containing silver–metal oxide should not be exposed to protective atmospheres because a reduction of the metal oxide, even in a thin contact surface layer the contact properties of these materials change. |

| − | |||

| − | contact tips containing silver–metal oxide should not be exposed to protective | ||

| − | atmospheres because a reduction of the metal oxide even in a thin contact | ||

| − | surface layer | ||

| − | === Resistance Brazing=== | + | ==== Resistance Brazing==== |

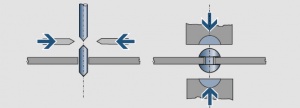

| − | In this process the resistive heating under electric currents is the source of | + | In this process, the resistive heating under electric currents is the source of thermal energy. For contact applications two methods are used for resistance brazing (<xr id="fig:Resistance brazing (schematic)"/><!--(Fig. 3.8)-->). |

| − | thermal energy. For contact applications two methods are used for resistance | + | <figure id="fig:Resistance brazing (schematic)"> |

| − | brazing | + | [[File:Resistance brazing (schematic).jpg|right|thumb|Figure 2: Resistance brazing (schematic)]] |

| − | + | </figure> | |

| − | During Direct Resistance Brazing the electric current flows straight through the | + | During Direct Resistance Brazing the electric current flows straight through the joint area composed of the contact tip, brazing alloy, flux and the contact carrier. These components are secured between the electrodes of a resistance brazing machine and heated by an electrical current until the brazing alloy liquefies. |

| − | joint area composed of the contact tip, brazing alloy, flux | ||

| − | carrier. These components are secured between the electrodes of a resistance | ||

| − | brazing machine and heated by an electrical current until the brazing alloy | ||

| − | liquefies. | ||

| − | In Indirect Resistance Brazing the current flows only through one of the | + | In Indirect Resistance Brazing the current flows only through one of the components to be joined (usually the non-precious contact carrier). This |

| − | components to be joined (usually the non-precious contact carrier). This | + | process allows to move the contact tip ("puddeling") when the brazing alloy is in its liquid stage and additionally remove residue bubbles from the heated and boiling flux and increase the percentage of the bonded area. Two different kinds of electrodes are used for resistance brazing: |

| − | process allows to move the contact tip ( | ||

| − | its liquid stage and | ||

| − | flux and increase the percentage of the bonded area. | ||

| − | Two different kinds of electrodes are used for resistance brazing: | ||

| − | *Electrodes from poorly conducting carbon containing materials (graphite)<br />The heat is created in the electrodes and thermally conducted into the joint area<br /> | + | *Electrodes from poorly conducting carbon containing materials (graphite)<br />The heat is created in the electrodes and thermally conducted into the joint area<br/> |

| − | *Electrodes from higher conductive and thermally stable metallic materials <br />The heat is created by the higher resistance in the joint area which, through selected designs, creates a constriction area for the electrical current in addition to the resistance of the components to be joined.<br /> | + | *Electrodes from higher conductive and thermally stable metallic materials<br />The heat is created by the higher resistance in the joint area which, through selected designs, creates a constriction area for the electrical current in addition to the resistance of the components to be joined.<br /> |

| − | Graphite electrodes are mainly used for indirect resistance brazing and for joint | + | Graphite electrodes are mainly used for indirect resistance brazing and for joint area > 100 mm<sup>2</sup>. For contact tips with a bottom area < 100 mm<sup>2</sup> which are already coated with a phosphorous containing brazing alloy, the heating time can be reduced to a degree that the softening of the contact carrier occurs only very closely to the joint area. For this "short-time brazing" specially designed metal electrodes with compositions selected for the specific assembly component pairings are used. |

| − | area > 100 mm<sup>2</sup>. For | ||

| − | already coated with a phosphorous containing brazing alloy the heating time can | ||

| − | be reduced to a degree that the softening of the contact carrier occurs only very | ||

| − | closely to the joint area. For this | ||

| − | electrodes with compositions selected for the specific assembly component | ||

| − | pairings are used. | ||

| − | The bond quality for normal resistance brazing with the application of flux ranges | + | The bond quality for normal resistance brazing with the application of flux ranges from 70 to 90% of contact size, for short-time welding these values can be exceeded significantly. |

| − | from 70 to 90% of contact size, for short-time welding these values can be | ||

| − | exceeded significantly. | ||

| − | + | ====Induction Brazing==== | |

| + | During induction brazing the heat energy is produced by an induction coil fed by a medium or high frequency generator. This creates an electromagnetic alternating field in the braze joint components which in turn generate eddy currents in the work piece. Because of the skin–effect, these currents and their resulting heat are created mainly on the surface of the assembly components. The distance of the inductor must be chosen in a way that the working temperature is generated almost simultaneously in the full joint area. For different contact shapes, the geometry of the induction coil can be optimized to obtain short working cycles. One of the advantages of this method, is the short heating time which limits the softening of the material components to be joined. Typical bond qualities of > 80% can be reached with this method, also for larger contact assemblies. The widely varying working times needed for the different brazing methods, are given in <xr id="tab:Brazing Times for Different Brazing Methods"/><!--(Table 3.1)-->. | ||

| − | = | + | <figtable id="tab:Brazing Times for Different Brazing Methods"> |

| − | + | <caption>'''<!--Tab.3.1:-->Brazing Times for Different Brazing Methods'''</caption> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {| class="twocolortable" style="text-align: left; font-size: 12px" | |

| + | |- | ||

| + | !Brazing method | ||

| + | !Brazing time in s (seconds) | ||

| + | |- | ||

| + | |Torch brazing | ||

| + | |3 - 100 | ||

| + | |- | ||

| + | |Direct resistance brazing | ||

| + | |1 - 3 | ||

| + | |- | ||

| + | |Indirect resistance brazing | ||

| + | |1 - 5 | ||

| + | |- | ||

| + | |Short time brazing (weld-brazing) | ||

| + | |0.1 - 1 | ||

| + | |- | ||

| + | |Induction brazing | ||

| + | |0.5 - 5 | ||

| + | |- | ||

| + | |Furnace brazing | ||

| + | |100 - 1000 | ||

| + | |} | ||

| + | </figtable> | ||

| − | |||

| − | |||

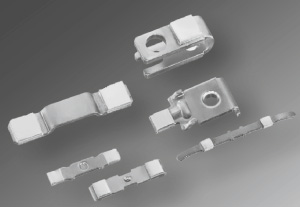

| − | *Contact materials | + | *Examples of brazed contact assemblies <xr id="fig:Examples of brazed contact assemblies"/> |

| + | <figure id="fig:Examples of brazed contact assemblies"> | ||

| + | [[File:Examples of brazed contact assemblies.jpg|right|thumb|Figure 3: Examples of brazed contact assemblies]] | ||

| + | </figure> | ||

| + | *Contact materials <br />Ag, Ag-Alloys., Ag/Ni, Ag/SnO<sub>2</sub>, Ag/ZnO and Ag/C with brazable backing, refractory materials on W -, WC- and Mo-basis<br /> | ||

| − | Ag, Ag | + | *Brazing alloys <br />L-Ag 15P, L-Ag 55Sn et.al.<br /> |

| − | |||

| − | |||

| − | * | + | *Carrier materials <br />Cu, Cu-Alloys. et al.<br /> |

| − | |||

| − | * | + | *Dimensions <br />Brazing area > 10 mm²<br /> |

| − | |||

| − | * | + | *Quality criteria <br />The testing of the braze joint quality is specified in agreements between the manufacturer and the user.<br /> |

| − | |||

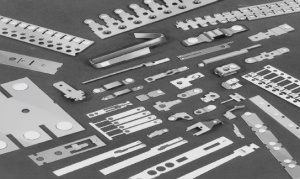

| − | + | === Welding Processes=== | |

| − | + | Welding of contact assemblies has both technological and economic importance. Because of the short heating times during welding, the carrier materials retain their hardness except for a very small heat affected area. Of the methods described below, resistance welding is the most widely utilized process. | |

| − | |||

| − | + | Because of miniaturization of electromechanical components laser welding has gained some application more recently. Friction welding is mainly used for bonding see [[Applications for Bonding Technologies|Applications for Bonding Technologies.]] Other welding methods such as ball (spheres) welding and ultrasonic welding are today used in only limited volume and therefore not covered in detail here. | |

| − | + | Special methods such as electron beam welding and cast-on attachment of contact materials to carrier components are mainly used for contact assemblies for medium and high voltage switchgear. | |

| − | |||

| − | |||

| − | methods | ||

| − | |||

| − | + | *Examples of Wire Welding (<xr id="fig:Examples of Wire Welding"/>) | |

| − | + | <figure id="fig:Examples of Wire Welding"> | |

| − | + | [[File:Examples of Wire Welding.jpg|right|thumb|Figure 4: Examples of Wire Welding]] | |

| − | + | </figure> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | ===Resistance Welding=== | + | ====Resistance Welding==== |

| − | Resistance welding is the process of electrically joining work pieces by creating | + | Resistance welding is the process of electrically joining work pieces by creating the required welding energy through current flow directly through the components without additional intermediate materials. For contact applications the most frequently used method is that of projection welding. Differently shaped weld projections are used on one of the two components to be joined (usually the contact). They reduce the area in which the two touch, creating a high electrical resistance and high current density which heats the constriction area to the melting point of the projections. Simultaneously exerted pressure from the electrodes further spreads out the liquefied metal over the weld joints area. The welding current and electrode force are controlling parameters for the resulting weld joint quality. The electrodes themselves are carefully designed and selected for material composition to best suit the weld requirements. |

| − | the required welding energy through current flow directly through the | ||

| − | components without additional intermediate materials. For contact applications | ||

| − | the most frequently used method is that of projection welding. Differently | ||

| − | shaped weld projections are used on one of the two components to be joined | ||

| − | (usually the contact). They reduce the area in which the two touch creating a | ||

| − | high electrical resistance and high current density which heats the constriction | ||

| − | area to the melting point of the projections. Simultaneously exerted pressure | ||

| − | from the electrodes further spreads out the liquefied metal over the weld joints | ||

| − | area. The welding current and electrode force are controlling parameters for the | ||

| − | resulting weld joint quality. The electrodes themselves are carefully designed | ||

| − | and selected for material composition to best suit the weld requirements. | ||

| − | The waveform of the weld current has a significant influence on the weld quality. | + | The waveform of the weld current has a significant influence on the weld quality. Besides 50 or 60 Hz AC current with phase angle control, also DC (6-phase from 3-phase rectified AC) and medium frequency (MF) weld generators are used for contact welding. In the latter the regular AC supply voltage is first rectified and then supplied back through a controlled DC/AC inverter as pulsed DC fed to a weld transformer. Medium frequency welding equipment usually works at frequencies between 1kHz to 10kHz. The critical parameters of current, voltage, and weld energy are electronically monitored and allow, through closed loop controls, to monitor and adjust the weld quality continuously. The very short welding times needed with these MF welding machines, result in very limited thermal stresses on the base material and also allow the reliable joining of otherwise difficult material combinations. |

| − | Besides 50 or 60 Hz AC current with phase angle control, also DC (6-phase | ||

| − | from 3-phase rectified AC) and medium frequency (MF) weld generators are | ||

| − | used for contact welding. In the latter the regular AC supply voltage is first | ||

| − | rectified and then supplied back through a controlled DC/AC inverter as pulsed | ||

| − | DC fed to a weld transformer. Medium frequency welding equipment usually | ||

| − | works at frequencies between 1kHz to 10kHz. The critical parameters of | ||

| − | current, voltage, and weld energy are electronically monitored and allow through | ||

| − | closed loop controls to monitor and adjust the weld quality continuously. The | ||

| − | very short welding times needed with these MF welding machines result in very | ||

| − | limited thermal stresses on the base material and also allow the reliable joining | ||

| − | of otherwise difficult material combinations. | ||

| − | ==== Vertical Wire Welding==== | + | ===== Vertical Wire Welding===== |

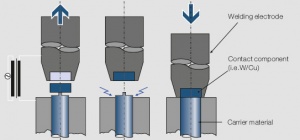

| − | During vertical wire welding the contact material is vertically fed in wire form | + | During vertical wire welding the contact material is vertically fed in wire form through a clamp, which at the same time acts as one of the weld electrodes (<xr id="fig:Vertical wire welding (schematic)"/>)<!--(Fig. 3.9)-->. |

| − | through a clamp which at the same time acts as one of the weld electrodes | + | <figure id="fig:Vertical wire welding (schematic)"> |

| − | + | [[File:Vertical wire welding (schematic).jpg|right|thumb|Figure 5: Vertical wire welding (schematic)]] | |

| − | + | </figure> | |

| − | |||

| − | |||

| − | wire | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | With one or more weld pulses the roof shaped wire end – from the previous cut-off operation – is welded to the base material strip while exerting pressure by the clamp-electrode. Under optimum weld conditions the welded area can reach up to 120% of the original cross-sectional area of the contact wire. After welding the wire is cut off by wedge shaped knives, forming again a roof shaped weld projection. The welded wire segment is subsequently formed into the desired contact shape by stamping or orbital forming. This welding process can easily be integrated into automated production lines. The contact material must however be directly weldable, meaning that it cannot contain graphite or metal oxides. | |

| − | + | *Contact materials <br />Ag, Ag-Alloys, Au- and Pd-Alloys, Ag/Ni <br /> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Carrier materials <br />Cu, Cu-Alloys, Cu clad Steel, et.al.<br /> | |

| − | |||

| − | |||

| − | |||

| − | + | *Dimensions (<xr id="fig:Vertical Wire Welding Dimensions"/>) | |

| + | <figure id="fig:Vertical Wire Welding Dimensions"> | ||

| + | [[File:Vertical Wire Welding Dimensions.jpg|right|thumb|Figure 6: Vertical Wire Welding Dimensions]] | ||

| + | </figure> | ||

| + | Functional quality criteria such as bonded area percentage or shear force are usually agreed upon between the supplier and user and defined in delivery specifications. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ===== Horizontal Wire or Profile Welding===== | |

| − | The | + | During horizontal welding the wire or profile contact material is fed at a shallow angle to the carrier strip material (<xr id="fig:Horizontal profile cut-off welding (schematic)"/>)<!--(Fig. 3.10)-->. |

| − | + | <figure id="fig:Horizontal profile cut-off welding (schematic)"> | |

| − | + | [[File:Horizontal profile cut-off welding (schematic).jpg|right|thumb|Figure 7: Horizontal profile cut-off welding (schematic)]] | |

| + | </figure> | ||

| + | The cut-off from the wire or profile is performed either directly by the electrode or in a separate cutting station. This horizontal feeding is suitable for welding single or multiple layer weld profiles. The profile construction allows to custom tailor the contact layer shape and thickness to the electrical load and required number of electrical switching operations. By choosing a two-layer contact configuration, multiple switching duty ranges can be satisfied. The following triple-layer profile is a good example for such a development: The top 5.0 μm AuAg8 layer is suitable to switch dry circuit electronic signals, the second or middle layer of 100 μm Ag/Ni 90/10 is used to switch relative high electrical loads and the bottom layer consists of an easily weldable alloy such as CuNi44 or CuNi9Sn2. The configuration of the bottom weld projections, i.e. size, shape, and number of welding nibs or weld rails are critically important for the final weld quality. | ||

| − | + | Because of the high production speed (approx. 700 welds per min) and the possibility to closely match the amount of precious contact material to the | |

| − | + | required need for specific switching applications, this joining process has gained great economical importance. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Contact materials <br />Au-Alloys, Pd-Alloys, Ag-Alloys, Ag/Ni, Ag/CdO, Ag/SnO<sub>2</sub>, Ag/ZnO, and Ag/C<br /> | |

| − | + | *Carrier materials <br />(weldable backing of multi-layer profiles) Ni, CuNi, CuNiFe, CuNiZn, CuSn, CuNiSn, and others.<br /> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Braze alloy layer <br />L-Ag 15P (CP 102 or BCUP-5)<br /> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | *Dimensions (<xr id="fig:Horizontal Wire Welding Dimensions"/>) |

| − | + | <figure id="fig:Horizontal Wire Welding Dimensions"> | |

| − | + | [[File:Horizontal Wire Welding Dimensions.jpg|right|thumb|Figure 8: Dimensions]] | |

| − | + | </figure> | |

| − | |||

| − | |||

| − | |||

| − | + | *Quality criteria | |

| − | + | Functional quality criteria such as bonded area percentage or shear force are usually agreed upon between the supplier and user and defined in delivery specifications. | |

| − | |||

| − | |||

| − | defined | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | =====Tip Welding===== | |

| − | + | Contact tips or formed contact parts produced by processes as described in [[Manufacturing of Single Contact Parts#Contact Tips|Contact Tips ]] are mainly attached by tip welding to their respective contact supports. In this process smaller contact parts such as Ag/C or Ag/W tips with good weldable backings are welded directly to the carrier parts. To improve the welding process and quality, the bottom side of these tips may have serrations (Ag/C) or shaped projections (Ag/W). These welding aids can also be formed on the carrier parts. Larger contact tips usually have an additional brazing alloy layer bonded to the bottom weld surface. | |

| − | + | Tip welding is also used for the attachment of weld buttons (see [[Manufacturing of Single Contact Parts#Weld Buttons|Weld Buttons]]). The welding is performed mostly semi or fully automated with the buttons oriented a specific way and fed into a welding station by suitably designed feeding mechanisms. | |

| − | + | ==== Percussion Welding==== | |

| − | + | This process of high current arc discharge welding requires the contact material and carrier to have two flat surfaces with one having a protruding nib. This nib acts as the ignition point for the high current arc (<xr id="fig:Percussion welding (schematic)"/><!--(Fig. 3.11)-->). | |

| + | <figure id="fig:Percussion welding (schematic)"> | ||

| + | [[File:Percussion welding (schematic).jpg|right|thumb|Figure 9: Percussion welding (schematic)]] | ||

| + | </figure> | ||

| + | The electric arc produces a molten layer of metallic material in the interface zone of the contact tip and carrier. Immediately afterwards, the two components are pushed together with substantial impact and speed, causing the liquid metal to form a strong joint across the whole interface area. | ||

| + | Because of the very short duration of the whole melt and bonding process, the two components, contact tip and carrier, retain their mechanical hardness and strength almost completely, except for the immediate thin joint area. The unavoidable weld splatter around the periphery of the joint must be mechanically removed in a secondary operation. The percussion welding process is mainly applied in the production of rod assemblies for high voltage switchgear. | ||

| − | * | + | *Contact materials <br />W/Cu, W/Ag, others<br /> |

| − | Cu, | ||

| − | * | + | *Carrier materials <br />Cu, Cu-Alloys, others<br /> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Dimensions <br />Weld surface area (flat) 6.0 to 25 mm diameter <br />Rectangular areas with up to 25 mm diagonals<br /> | |

| − | * | + | *Quality criteria <br />Test methods for bond quality are agreed upon between supplier and user<br /> (<xr id="fig:Examples for percussion welded contact parts"/>)<!--(Fig. 3.13)--> |

| − | + | <figure id="fig:Examples for percussion welded contact parts"> | |

| − | + | [[File:Examples for percussion welded contact parts.jpg|right|thumb|Figure 10: Examples for percussion welded contact parts]] | |

| + | </figure> | ||

| − | + | ====Laser Welding==== | |

| − | + | This contact attachment process is also one of the liquid phase welding methods. Solid phase lasers are predominantly used for welding and brazing. | |

| − | + | The exact guiding and focusing of the laser beam from the source to the joint location is highly important to ensure the most efficient energy absorption in the joint, where the light energy is converted to heat. Advantages of this method are the touch-less energy transport, which avoids any possible contamination of contact surfaces, the very well defined weld effected zone, the exact positioning of the weld spot and the precise control of weld energy. | |

| − | + | Laser welding is mostly applied for rather small contact parts to thin carrier materials. To avoid any defects in the contact portion, the welding is usually performed through the carrier material. Using a higher powered laser and beam splitting allows a high production speed with weld joints created at multiple spots at the same time. | |

| − | |||

| − | + | ==== Special Welding and Attachment Processes==== | |

| − | + | In high voltage switchgear, the contact parts are exposed to high mechanical and thermal stresses. This requires mechanically strong and 100% metallurgically bonded joints between the contacts and their carrier supports, which cannot be achieved by the traditional attachment methods. The two processes of electron beam welding and the cast-on with copper can, however, be used to solve this problem. | |

| − | + | ===== Electron Beam Welding===== | |

| − | + | The electron beam welding is a joining process which has shown its suitability for high voltage contact assemblies. A sharply focused electron beam has sufficient energy to penetrate the mostly thicker parts and generate a locally defined molten area so that the carrier component is only softened in a narrow zone (1 – 4 mm). This allows the attachment of Cu/W contacts and also hard and thermally stable copper alloys as for example CuCrZr for spring hard contact tulips (<xr id="fig:Contact tulips with CuW welded to CuCrZr carriers"/><!--(Fig. 3.12)-->). | |

| − | + | <figure id="fig:Contact tulips with CuW welded to CuCrZr carriers"> | |

| − | + | [[File:Contact tulips with CuW welded to CuCrZr carriers.jpg|right|thumb|Figure 11: Contact tulips with CuW welded to CuCrZr carriers]] | |

| + | </figure> | ||

| − | === | + | ===== Cast-On of Copper===== |

| + | The cast-on of liquid copper to pre-fabricated W/Cu contact parts is performed in special casting molds. This results in a seamless joint between the W/Cu and the copper carrier. The hardness of the copper is then increased by a secondary forming or deep-drawing operation. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==References== | ==References== | ||

[[:Manufacturing Technologies for Contact Parts#References|References]] | [[:Manufacturing Technologies for Contact Parts#References|References]] | ||

| + | |||

| + | [[de:Bestückung_von_Einzelkontakten]] | ||

Latest revision as of 12:51, 26 January 2023

The following segments give an overview of the usually applied attachment technologies for contact parts to carrier components. They include mechanical as well as brazing and welding methods used for electrical contact assemblies.

Mechanical Attachment Processes

Rivet staking and the insertion and forming of wire segments into pre-stamped carrier parts or strips with punched holes are the most commonly used methods for the mechanical attachment of contact materials.

Riveting (or staking) for smaller volumes of assemblies is mostly done on mechanical, pneumatic or magnetically operated presses. For larger volumes the staking process is integrated into a progressive die for fully automated assembly. Rivets are fed in the correct orientation through special feeding tracks into the staking station of the tool. To ensure a mechanically secure attachment, the rivet shank must be dimensioned correctly. As a general rule, the shank length of the rivet should be about 1/3 longer than the thickness of the carrier material. For switch-over contacts part of the rivet shank is formed into the secondary rivet head. To minimize deformation of the contact blade carriers, especially thin ones, this head forming is often performed by orbital riveting.

The insertion and forming of wire segments can be easily integrated into stamp and bending multi-slide tooling (Figure 1). Compared to the use of composite rivets this process uses more precious contact material but for silver based contact materials these costs are often offset by higher and more efficient manufacturing speeds. For the more brittle Ag/SnO2 materials however, close attention must be paid to the danger of crack formation.

Brazing Processes

Brazing is a thermal process for the metallurgical bonding of metallic materials in which a third metal component (brazing alloy or solder) is added. In addition a flux or processing in a protective atmosphere is applied to eliminate oxidation of the non-precious carrier. The melting range of the brazing alloy starts at the beginning of the melting (solidus temperature) all the way to complete liquid phase (liquidus temperature). This range always is below the melting points of the two materials to be joined. During the brazing process with solubility of the materials in each other, diffusion processes are thermally activated by which elements of the base material diffuse into the brazing alloy and elements of the braze alloy diffuse into brazing alloy. This increases the bond strength and therefore the mechanical stability of the brazed joint.

For attachment of contact parts to carrier base materials, only brazing alloys (as opposed to solders) are used. The reason is the higher softening temperature and melting point as well as higher mechanical strength and electrical conductivity of these alloys. The brazing alloys and fluxes used for electrical contact attachment are listed in Brazing Alloys and Fluxes in more detail. Following the most frequently used brazing methods are described. References to the bond quality are given according to the test methods described in Evaluation of Braze or Weld Joints

Flame (or Torch) Brazing

The easiest way to produce braze joints, is the use of a gas torch fueled by a burning gas and air or oxygen containing gas mixes. For higher production volumes, partial automation is applied. The parts to be assembled are transported after adding the suitable amounts of brazing alloy and flux through a series of fixed gas burners on a turntable or belt driven brazing machine. To limit the amount of flux or gas inclusions, it is recommended to slightly move the contact tips back and forth (also known as puddeling) as soon as the brazing alloy is liquefied. The bonded area achieved in torch brazing is typically 65 – 90% of the contact foot print, depending on the size and geometry of the contact tip.

Furnace Brazing

Furnace brazing is usually defined as brazing in a protective atmosphere or in vacuum. Both processes do not require the use of fluxes.

The protective atmosphere brazing is conducted in batch operation in either muffle or pot furnaces or as a continuous process in belt furnaces, using a reducing atmosphere of pure hydrogen (H2) or dissociated ammonia (H2,N2).

A vacuum is a very efficient protective environment for brazing but using vacuum furnaces is more complicated and rather inefficient. Therefore this process is only used for materials and assemblies that are sensitive to oxygen, nitrogen, or hydrogen impurities. Not suitable for vacuum brazing are materials which contain components with a high vapor pressure.

Parts with oxygen containing copper supports should not be brazed in reducing atmospheres because of their susceptibility to hydrogen embrittlement. Similarly contact tips containing silver–metal oxide should not be exposed to protective atmospheres because a reduction of the metal oxide, even in a thin contact surface layer the contact properties of these materials change.

Resistance Brazing

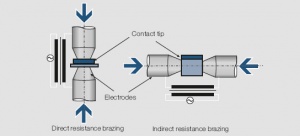

In this process, the resistive heating under electric currents is the source of thermal energy. For contact applications two methods are used for resistance brazing (Figure 2).

During Direct Resistance Brazing the electric current flows straight through the joint area composed of the contact tip, brazing alloy, flux and the contact carrier. These components are secured between the electrodes of a resistance brazing machine and heated by an electrical current until the brazing alloy liquefies.

In Indirect Resistance Brazing the current flows only through one of the components to be joined (usually the non-precious contact carrier). This process allows to move the contact tip ("puddeling") when the brazing alloy is in its liquid stage and additionally remove residue bubbles from the heated and boiling flux and increase the percentage of the bonded area. Two different kinds of electrodes are used for resistance brazing:

- Electrodes from poorly conducting carbon containing materials (graphite)

The heat is created in the electrodes and thermally conducted into the joint area

- Electrodes from higher conductive and thermally stable metallic materials

The heat is created by the higher resistance in the joint area which, through selected designs, creates a constriction area for the electrical current in addition to the resistance of the components to be joined.

Graphite electrodes are mainly used for indirect resistance brazing and for joint area > 100 mm2. For contact tips with a bottom area < 100 mm2 which are already coated with a phosphorous containing brazing alloy, the heating time can be reduced to a degree that the softening of the contact carrier occurs only very closely to the joint area. For this "short-time brazing" specially designed metal electrodes with compositions selected for the specific assembly component pairings are used.

The bond quality for normal resistance brazing with the application of flux ranges from 70 to 90% of contact size, for short-time welding these values can be exceeded significantly.

Induction Brazing

During induction brazing the heat energy is produced by an induction coil fed by a medium or high frequency generator. This creates an electromagnetic alternating field in the braze joint components which in turn generate eddy currents in the work piece. Because of the skin–effect, these currents and their resulting heat are created mainly on the surface of the assembly components. The distance of the inductor must be chosen in a way that the working temperature is generated almost simultaneously in the full joint area. For different contact shapes, the geometry of the induction coil can be optimized to obtain short working cycles. One of the advantages of this method, is the short heating time which limits the softening of the material components to be joined. Typical bond qualities of > 80% can be reached with this method, also for larger contact assemblies. The widely varying working times needed for the different brazing methods, are given in Table 1.

| Brazing method | Brazing time in s (seconds) |

|---|---|

| Torch brazing | 3 - 100 |

| Direct resistance brazing | 1 - 3 |

| Indirect resistance brazing | 1 - 5 |

| Short time brazing (weld-brazing) | 0.1 - 1 |

| Induction brazing | 0.5 - 5 |

| Furnace brazing | 100 - 1000 |

- Examples of brazed contact assemblies Figure 3

- Contact materials

Ag, Ag-Alloys., Ag/Ni, Ag/SnO2, Ag/ZnO and Ag/C with brazable backing, refractory materials on W -, WC- and Mo-basis

- Brazing alloys

L-Ag 15P, L-Ag 55Sn et.al.

- Carrier materials

Cu, Cu-Alloys. et al.

- Dimensions

Brazing area > 10 mm²

- Quality criteria

The testing of the braze joint quality is specified in agreements between the manufacturer and the user.

Welding Processes

Welding of contact assemblies has both technological and economic importance. Because of the short heating times during welding, the carrier materials retain their hardness except for a very small heat affected area. Of the methods described below, resistance welding is the most widely utilized process.

Because of miniaturization of electromechanical components laser welding has gained some application more recently. Friction welding is mainly used for bonding see Applications for Bonding Technologies. Other welding methods such as ball (spheres) welding and ultrasonic welding are today used in only limited volume and therefore not covered in detail here. Special methods such as electron beam welding and cast-on attachment of contact materials to carrier components are mainly used for contact assemblies for medium and high voltage switchgear.

- Examples of Wire Welding (Figure 4)

Resistance Welding

Resistance welding is the process of electrically joining work pieces by creating the required welding energy through current flow directly through the components without additional intermediate materials. For contact applications the most frequently used method is that of projection welding. Differently shaped weld projections are used on one of the two components to be joined (usually the contact). They reduce the area in which the two touch, creating a high electrical resistance and high current density which heats the constriction area to the melting point of the projections. Simultaneously exerted pressure from the electrodes further spreads out the liquefied metal over the weld joints area. The welding current and electrode force are controlling parameters for the resulting weld joint quality. The electrodes themselves are carefully designed and selected for material composition to best suit the weld requirements.

The waveform of the weld current has a significant influence on the weld quality. Besides 50 or 60 Hz AC current with phase angle control, also DC (6-phase from 3-phase rectified AC) and medium frequency (MF) weld generators are used for contact welding. In the latter the regular AC supply voltage is first rectified and then supplied back through a controlled DC/AC inverter as pulsed DC fed to a weld transformer. Medium frequency welding equipment usually works at frequencies between 1kHz to 10kHz. The critical parameters of current, voltage, and weld energy are electronically monitored and allow, through closed loop controls, to monitor and adjust the weld quality continuously. The very short welding times needed with these MF welding machines, result in very limited thermal stresses on the base material and also allow the reliable joining of otherwise difficult material combinations.

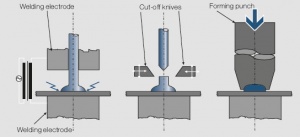

Vertical Wire Welding

During vertical wire welding the contact material is vertically fed in wire form through a clamp, which at the same time acts as one of the weld electrodes (Figure 5).

With one or more weld pulses the roof shaped wire end – from the previous cut-off operation – is welded to the base material strip while exerting pressure by the clamp-electrode. Under optimum weld conditions the welded area can reach up to 120% of the original cross-sectional area of the contact wire. After welding the wire is cut off by wedge shaped knives, forming again a roof shaped weld projection. The welded wire segment is subsequently formed into the desired contact shape by stamping or orbital forming. This welding process can easily be integrated into automated production lines. The contact material must however be directly weldable, meaning that it cannot contain graphite or metal oxides.

- Contact materials

Ag, Ag-Alloys, Au- and Pd-Alloys, Ag/Ni

- Carrier materials

Cu, Cu-Alloys, Cu clad Steel, et.al.

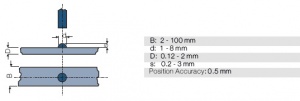

- Dimensions (Figure 6)

Functional quality criteria such as bonded area percentage or shear force are usually agreed upon between the supplier and user and defined in delivery specifications.

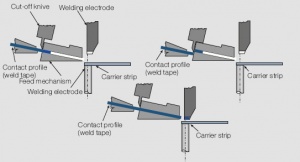

Horizontal Wire or Profile Welding

During horizontal welding the wire or profile contact material is fed at a shallow angle to the carrier strip material (Figure 7).

The cut-off from the wire or profile is performed either directly by the electrode or in a separate cutting station. This horizontal feeding is suitable for welding single or multiple layer weld profiles. The profile construction allows to custom tailor the contact layer shape and thickness to the electrical load and required number of electrical switching operations. By choosing a two-layer contact configuration, multiple switching duty ranges can be satisfied. The following triple-layer profile is a good example for such a development: The top 5.0 μm AuAg8 layer is suitable to switch dry circuit electronic signals, the second or middle layer of 100 μm Ag/Ni 90/10 is used to switch relative high electrical loads and the bottom layer consists of an easily weldable alloy such as CuNi44 or CuNi9Sn2. The configuration of the bottom weld projections, i.e. size, shape, and number of welding nibs or weld rails are critically important for the final weld quality.

Because of the high production speed (approx. 700 welds per min) and the possibility to closely match the amount of precious contact material to the required need for specific switching applications, this joining process has gained great economical importance.

- Contact materials

Au-Alloys, Pd-Alloys, Ag-Alloys, Ag/Ni, Ag/CdO, Ag/SnO2, Ag/ZnO, and Ag/C

- Carrier materials

(weldable backing of multi-layer profiles) Ni, CuNi, CuNiFe, CuNiZn, CuSn, CuNiSn, and others.

- Braze alloy layer

L-Ag 15P (CP 102 or BCUP-5)

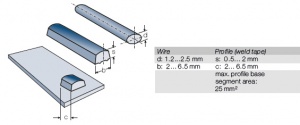

- Dimensions (Figure 8)

- Quality criteria

Functional quality criteria such as bonded area percentage or shear force are usually agreed upon between the supplier and user and defined in delivery specifications.

Tip Welding

Contact tips or formed contact parts produced by processes as described in Contact Tips are mainly attached by tip welding to their respective contact supports. In this process smaller contact parts such as Ag/C or Ag/W tips with good weldable backings are welded directly to the carrier parts. To improve the welding process and quality, the bottom side of these tips may have serrations (Ag/C) or shaped projections (Ag/W). These welding aids can also be formed on the carrier parts. Larger contact tips usually have an additional brazing alloy layer bonded to the bottom weld surface.

Tip welding is also used for the attachment of weld buttons (see Weld Buttons). The welding is performed mostly semi or fully automated with the buttons oriented a specific way and fed into a welding station by suitably designed feeding mechanisms.

Percussion Welding

This process of high current arc discharge welding requires the contact material and carrier to have two flat surfaces with one having a protruding nib. This nib acts as the ignition point for the high current arc (Figure 9).

The electric arc produces a molten layer of metallic material in the interface zone of the contact tip and carrier. Immediately afterwards, the two components are pushed together with substantial impact and speed, causing the liquid metal to form a strong joint across the whole interface area. Because of the very short duration of the whole melt and bonding process, the two components, contact tip and carrier, retain their mechanical hardness and strength almost completely, except for the immediate thin joint area. The unavoidable weld splatter around the periphery of the joint must be mechanically removed in a secondary operation. The percussion welding process is mainly applied in the production of rod assemblies for high voltage switchgear.

- Contact materials

W/Cu, W/Ag, others

- Carrier materials

Cu, Cu-Alloys, others

- Dimensions

Weld surface area (flat) 6.0 to 25 mm diameter

Rectangular areas with up to 25 mm diagonals

- Quality criteria

Test methods for bond quality are agreed upon between supplier and user

(Figure 10)

Laser Welding

This contact attachment process is also one of the liquid phase welding methods. Solid phase lasers are predominantly used for welding and brazing. The exact guiding and focusing of the laser beam from the source to the joint location is highly important to ensure the most efficient energy absorption in the joint, where the light energy is converted to heat. Advantages of this method are the touch-less energy transport, which avoids any possible contamination of contact surfaces, the very well defined weld effected zone, the exact positioning of the weld spot and the precise control of weld energy.

Laser welding is mostly applied for rather small contact parts to thin carrier materials. To avoid any defects in the contact portion, the welding is usually performed through the carrier material. Using a higher powered laser and beam splitting allows a high production speed with weld joints created at multiple spots at the same time.

Special Welding and Attachment Processes

In high voltage switchgear, the contact parts are exposed to high mechanical and thermal stresses. This requires mechanically strong and 100% metallurgically bonded joints between the contacts and their carrier supports, which cannot be achieved by the traditional attachment methods. The two processes of electron beam welding and the cast-on with copper can, however, be used to solve this problem.

Electron Beam Welding

The electron beam welding is a joining process which has shown its suitability for high voltage contact assemblies. A sharply focused electron beam has sufficient energy to penetrate the mostly thicker parts and generate a locally defined molten area so that the carrier component is only softened in a narrow zone (1 – 4 mm). This allows the attachment of Cu/W contacts and also hard and thermally stable copper alloys as for example CuCrZr for spring hard contact tulips (Figure 11).

Cast-On of Copper

The cast-on of liquid copper to pre-fabricated W/Cu contact parts is performed in special casting molds. This results in a seamless joint between the W/Cu and the copper carrier. The hardness of the copper is then increased by a secondary forming or deep-drawing operation.