Physical Effects in Sliding and Connector Contacts

From Electrical Contacts

Revision as of 15:52, 1 April 2014 by Doduco Redaktion (talk | contribs) (→6.4.5 Physical Effects in Sliding and Connector Contacts)

6.4.5 Physical Effects in Sliding and Connector Contacts

- Mechanical wear of sliding contacts

| dV/dx = k x FK /3 HW |

| dV/dx Wear volume in mm3 per slide path length in mm |

| k Coefficient of frictional wear |

| HW Hardness of the softer material (Brinell or Vickers units) |

| FK Contact force in cN |

| Wear coefficient k during material transfer |

| Silver – Silver 120 x 10-4 |

| Platinum – Platinum 400 x 10-4 |

| Silver – Platinum 1.3 x 10-4 |

| Coefficient of fractional wear k during wear loss |

| Silver – silver 8 x 10-4 |

| Gold – gold 9 x 10-4 |

| Platinum – platinum 40 x 10-4 |

| Silver – gold 9 x 10-4 |

| Silver – platinum 5 x 10-4 |

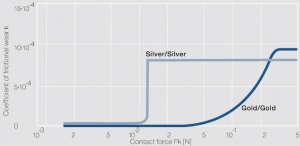

Fig. 6.15: Coefficient of frictional wear for the wear loss of sliding contacts Silver/Silver and hard gold/hard gold as a function of the contact force

- Contact behavior of connectors

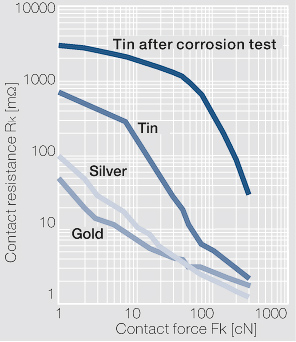

Fig. 6.16: Contact resistance R as a function k of the contact force F for different surface k coating materials. Measured against a spherical gold probe; I = 10 mA, U < 20 mV

Fig. 6.17: Contact resistance R as a function k of the fretting wear cycles for different surface coating materials

Tab.6.4: Surface Coating Materials for Connectors