Difference between revisions of "Test Procedures for the Communications Technology"

Doduco Admin (talk | contribs) |

Doduco Admin (talk | contribs) |

||

| Line 58: | Line 58: | ||

Electrical life, failure rate and reliability are statistical quantities. To determine the electrical life, the relays are switching the specified load in an accelerated way with higher switching frequency, until the first pre-defined failure occurs. The number of switching operations reached for the representative sample size of relays is determined through statistically valid test setups using Weibull distributions. For all switching operations, the failure criteria must be monitored and recorded. | Electrical life, failure rate and reliability are statistical quantities. To determine the electrical life, the relays are switching the specified load in an accelerated way with higher switching frequency, until the first pre-defined failure occurs. The number of switching operations reached for the representative sample size of relays is determined through statistically valid test setups using Weibull distributions. For all switching operations, the failure criteria must be monitored and recorded. | ||

<figure id="fig:Statistical evaluation of the electrical life of relays"> | <figure id="fig:Statistical evaluation of the electrical life of relays"> | ||

| − | [[File:Statistical evaluation of the electrical life of relays.jpg|right|thumb|Figure | + | [[File:Statistical evaluation of the electrical life of relays.jpg|right|thumb|Figure 3: Statistical evaluation of the electrical life of relays (Operating parameters: 220VAC, 8A, 0.1Hz, resistive load; contact material AgCdO 90/10)]] |

</figure> | </figure> | ||

| Line 70: | Line 70: | ||

The DC load conditions are specified in the relevant standards (for ex. Telecom Specifications). | The DC load conditions are specified in the relevant standards (for ex. Telecom Specifications). | ||

<figure id="fig:Principle and sequence of testing with electronic load simulation"> | <figure id="fig:Principle and sequence of testing with electronic load simulation"> | ||

| − | [[File:Principle and sequence of testing with electronic load simulation.jpg|right|thumb|Figure | + | [[File:Principle and sequence of testing with electronic load simulation.jpg|right|thumb|Figure 4: Principle and sequence of testing with electronic load simulation]] |

</figure> | </figure> | ||

<figure id="fig:Automotive relays under motor load"> | <figure id="fig:Automotive relays under motor load"> | ||

| − | [[File:Automotive relays under motor load.jpg|right|thumb|Figure | + | [[File:Automotive relays under motor load.jpg|right|thumb|Figure 5: Automotive relays under motor load: Results of electrical life testing using different contact materials]] |

</figure> | </figure> | ||

| Line 112: | Line 112: | ||

The full clarification of causes for switching device failures, for example relays, is most important for quality assurance. As a starting point, the full history of the relay, such as electrical load, environmental conditions etc. must be recorded. The process flow chart in (<xr id="fig:Flow diagram for evaluation of failure cause in switching devices for communications technology"/><!--(Fig. 13.10)-->) clearly describes a proven way to conduct a failure analysis. | The full clarification of causes for switching device failures, for example relays, is most important for quality assurance. As a starting point, the full history of the relay, such as electrical load, environmental conditions etc. must be recorded. The process flow chart in (<xr id="fig:Flow diagram for evaluation of failure cause in switching devices for communications technology"/><!--(Fig. 13.10)-->) clearly describes a proven way to conduct a failure analysis. | ||

<figure id="fig:Flow diagram for evaluation of failure cause in switching devices for communications technology"> | <figure id="fig:Flow diagram for evaluation of failure cause in switching devices for communications technology"> | ||

| − | [[File:Flow diagram for evaluation of failure cause in switching devices for communications technology.jpg|right|thumb|Figure | + | [[File:Flow diagram for evaluation of failure cause in switching devices for communications technology.jpg|right|thumb|Figure 6: Flow diagram for evaluation of failure cause in switching devices for communications technology]] |

</figure> | </figure> | ||

Following all procedures of such a failure evaluation carefully, the root cause of the defect can most likely be established in order to implement preventive measures limiting future occurrences. | Following all procedures of such a failure evaluation carefully, the root cause of the defect can most likely be established in order to implement preventive measures limiting future occurrences. | ||

Revision as of 08:23, 8 December 2022

Contents

Test Procedures for the Communications Technology

Testing of the contact behavior in the communications technology is usually performed on the actual devices such as for example in relays. Experience has shown that the interaction between all design and functional parameters such as contact forces, relative movement and electrical loads are determining the failure mode. Therefore only statistical performance tests on a larger number of switching devices lead to meaningful results.

One must differentiate between static tests (for ex. contact resistance) and dynamic ones (for ex. electrical life). In certain electromechanical components and switching devices, the contacts can be exposed to both, static and dynamic stresses (for ex. connectors, relays, switches, pushbuttons, circuit breakers). For statically stressed components, the life expectancy is usually expressed as a time period, i.e. hours, while for dynamically stressed ones the expected functional life is defined as numbers of operations or switching cycles.

Measuring of Contact Resistance

The contact resistance in the new stage is for most contact containing electromechanical components a characteristic, defining their quality. It is defined in most standards and acceptance specifications of users. It is important however, that a clear definition of the test conditions is given with the specification.

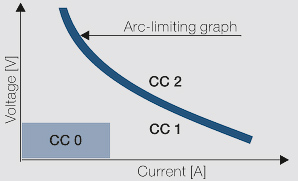

The standard IEC DIN EN 61810-2 defines the application areas of relays according to their load application categories (CC) (Figure 1). The categories CC1 and CC2 are separated by the arc-limiting graph (DC breaking capacity). Switching operations below the graph do not generate electrical arcs, those above the graph are accompanied by electrical arcing.

- CC1 is characteristic for switching operations in control circuits at low voltages, for ex. SPS input signals

- CC2 is typical for release circuits in low voltage controls which for example actuate contactors (220 - 240 VAC)

- CC0 as a special application describes the voltage – current range for dry circuits

The measuring conditions for contact resistance measurement are defined per IEC DIN EN 61810-7 for the contact load categories as follows:

- Contact load category CC0: < 30 mV; < 10 mA

- Contact load category CC1: < 10 V; < 100 mA

- Contact load category CC2: < 30 V; < 1 A

For contacts designed to cover multiple load ranges, the measuring category for the lowest range must be used. Contact resistance measurement usually is carried out following the 4-wire method at a temperature of 27°C ± 1°C and relative humidity of 63 – 67% RH.

By adding an upper threshold value (for ex. the 90% contact resistance value of the statistical cumulative frequency), it can be assured that that contacts are fulfilling the requirement from their new state for the respective application. The current carrying in normal dynamical operating devices is also assured by this measurement procedure. It is however not a valid indicator for the further behavior in a given application. To determine this, electrical life tests have to be performed under real electrical loads.

Life Testing

Electrical life is defined as the number of operations under a defined load (make under load current, current carrying, breaking the load current). The total sequence of this switching cycle leads for the specific design parameters of a relay (bounce characteristics, materials, etc.) to the phenomena responsible for the later device failure, such as increased contact resistance, material transfer, arc erosion and contact welding, for example (Figure 2).

As experience shows, failures during load switching are usually related to deterioration of the contact parts. Therefore, the mechanical life must always be higher than the electrical life under the required load conditions. Typically the mechanical life is about 10 times higher than the electrical one.

Criteria for Functional Life

In the communications technology the functional life criteria for switching devices, following conventional standards and specifications are:

- Failure to close by exceeding an upper limit for the contact resistance

- Failure to open by contact welding at a higher force than specified or by mechanical interlocking

- Switching characteristics strongly changed by arc erosion or material transfer

As opposed to electronic components, failures in electromechanical devices can occur once and not repeat at all or at considerably later stages of the life time.

Because of this, an exact definition for the failure mode must be provided. In most cases the first failure occurrence is defined as the overall device failure, since relays are increasingly used in safety related electrical circuits. Failures to open because of contact welding must be very critically examined. In some instances a weak weld or “sticking” of the contacts can cause a delayed opening and separation of the contacts by themselves. Therefore it is useful to define weld failures as "non-opening after a specified time", approx. 1 sec. after the actual switching-off event.

Determination of Functional Life

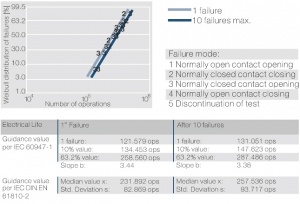

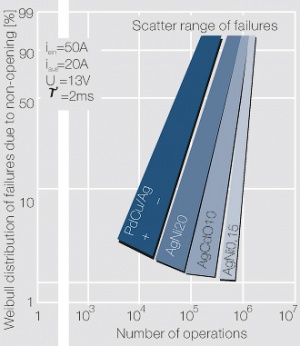

Electrical life, failure rate and reliability are statistical quantities. To determine the electrical life, the relays are switching the specified load in an accelerated way with higher switching frequency, until the first pre-defined failure occurs. The number of switching operations reached for the representative sample size of relays is determined through statistically valid test setups using Weibull distributions. For all switching operations, the failure criteria must be monitored and recorded.

The large quantity of data generated during the tests can be only analyzed with computer based test systems. After all the relays failed, a failure statistic is calculated and the expected electrical life is calculated based on the specified switching and operating criteria. (Figure 3) shows in form of a Weibull diagram the results of a relay life test for a sampling of switching relays under a resistive AC load with failures after the first and the 10th occurrence analyzed. From such electrical life test it is also possible to statistically predict the failure rate of relays under certain specified load conditions.

Testing Technology

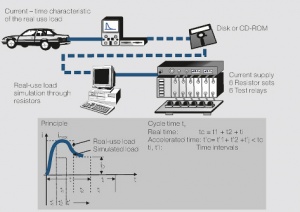

The test set-ups for relay tests consist of a load part, which allows the selection of specific electrical loads and a control / monitoring part, which typically includes the measuring devices with data collection and mostly also a computer for data analysis (Figure 4). Variations for testing of different relay types concern mostly the load circuits, the sample size of test specimens and the frequency of testing.

- Signal Relays (Low Current Relays)

The DC load conditions are specified in the relevant standards (for ex. Telecom Specifications).

- Switching of “dry circuits” with monitoring of the contact resistance, in some cases at elevated temperatures

- Two load conditions at 30 W (125 VDC, 0.24 A and 37.5 VDC, 0.8 A

- Two wiring load conditions

- Two different overload conditions at 60 W (250 VDC, 0.24 A and 37.7 VDC, 1.6 A)

The number of test samples varies between 3 and 20 pieces, depending on the load; the switching frequency varies between 0.3 and 10 Hz. The test set-up has to follow the regulations of IEC DIN EN 61810-2.

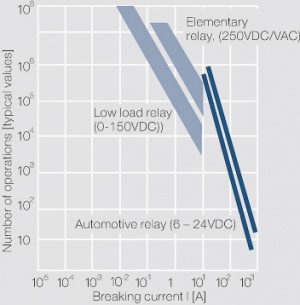

- Elementary Relays (or General Purpose Relays / Switching Relays)

For these relays, electrical life tests according to their various DC as well as AC load conditions are required. These load conditions are also defined in well known VDE standards for power engineering products (IEC/EN 60947-4-1, IEC DIN EN 61810-2). The number of samples (mostly < 10 relays) and testing frequency are defined. Often tests for these load characteristics are used for the selection of optimum contact materials.

- Automotive Relays

For these relays electrical life tests are conducted under the DC voltage used in the on-board circuitry. Since no standardized tests have been established for automotive relays, the electrical loads are agreed upon between the supplier and the end user. The multitude of load conditions, i.e. resistive, inductive motor and lamp loads require a flexible set-up of suitable test equipment (Figure 4).

During accelerated life tests the following parameters from real life loads must be observed:

- Lamp loads are strongly temperature dependent resistive loads. Therefore a sufficient cooling time of the bulb filaments must be allowed.

- The actual loads used in test experiments wear over time and must be replaced at regular intervals.

- Tests at low temperatures require large cooled climate chambers and extended cool-down times.

These requirements lead to the need to simulate the real life loads through electronically controlled load circuits. Such computerized electronic load circuit simulations easily allow the test sequences to be controlled and monitored:

- Time saving test runs for lamp loads by reducing interval times, monitoring of each switching operation for electrical life criteria, allowing to recognize non separation of the contacts after a pre-set time limit to be classified as a relay failure

Results of relay life testing using different contact materials are illustrated as an example in (Figure 5 ). For each contact material, 10 relays were tested under the prescribed motor load until a failure due to non-opening was detected. For this specific load condition AgNiO15 was found to be the best suited contact material.

Failure Analysis

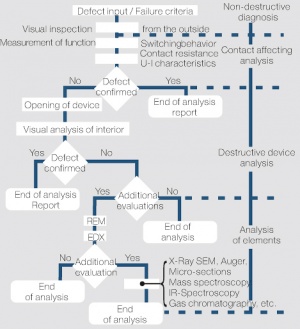

The full clarification of causes for switching device failures, for example relays, is most important for quality assurance. As a starting point, the full history of the relay, such as electrical load, environmental conditions etc. must be recorded. The process flow chart in (Figure 6) clearly describes a proven way to conduct a failure analysis.

Following all procedures of such a failure evaluation carefully, the root cause of the defect can most likely be established in order to implement preventive measures limiting future occurrences.