Difference between revisions of "Low and Medium Electrical Loads"

(→6.1.1 Low and Medium Electrical Loads) |

(→6.1.1 Low and Medium Electrical Loads) |

||

| Line 17: | Line 17: | ||

*Low Power (Load) Contacts <br />U > 10V <br />I > 300mA<br /> | *Low Power (Load) Contacts <br />U > 10V <br />I > 300mA<br /> | ||

| − | *Dry Circuit Contacts | + | *'''Dry Circuit Contacts''' |

This load range is characterized by the fact that the voltage is below the softening voltage of the respective contact material (< approx. 80mV) and the current stays below 10mA. Because of this low electrical load the switching occurs without any electrical discharge and also without any significant thermal stress on the contact spot. The main influences on the contact behavior are therefore chemical and mechanical in nature, such as contamination, and dust or abrasion particles for-med on the contact surfaces. The required high reliability can only be reached by using highly corrosion resistant contact materials. Since dust particle contamina-tions play a major role in determining the failure rate of these contacts, double (bifurcated) or multiple contacts are used frequently. | This load range is characterized by the fact that the voltage is below the softening voltage of the respective contact material (< approx. 80mV) and the current stays below 10mA. Because of this low electrical load the switching occurs without any electrical discharge and also without any significant thermal stress on the contact spot. The main influences on the contact behavior are therefore chemical and mechanical in nature, such as contamination, and dust or abrasion particles for-med on the contact surfaces. The required high reliability can only be reached by using highly corrosion resistant contact materials. Since dust particle contamina-tions play a major role in determining the failure rate of these contacts, double (bifurcated) or multiple contacts are used frequently. | ||

Revision as of 14:52, 9 May 2014

6.1.1 Low and Medium Electrical Loads

Switching processes at low and medium electrical loads are experienced for example in relays and switches for the measuring technology, telecommunications, automotive usage, and appliances. The switching voltage ranges from μV to 400V with currents between μA and about 100A.

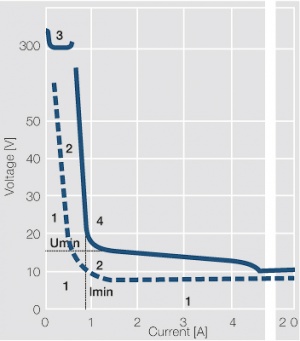

Guided by empirically developed arc-limiting graphs typical switching processes can be distinguished. As Figure 1 Fig. 6.1 illustrates, voltage and current determine if switching occurs without arcing, results in a glow discharge, short instable arcs are generated, or a fully developed electrical arc is created. The more exact current-voltage curve characte-ristics are depending on the electrical contact material used. They also depend on the contact gap and the atmosphere the switching occurs in; an ambient air atmosphere is assumed in the shown schematic example.

For the different requirements on the electrical contacts in various applications it is useful to differentiate across the broad spectrum of possible load conditions guided by the arc-limiting graphs between four different partial ranges which result in typical physical effects:

- Dry Circuit Contacts

U < 80mV

I < 10mA

- Low Level (Load) Contacts

U = 80 to 300mV

I < 10mA

- Intermediate Level (Load) Contacts

U = 300mV – 10V

I = 10mA – 100mA

- Low Power (Load) Contacts

U > 10V

I > 300mA

- Dry Circuit Contacts

This load range is characterized by the fact that the voltage is below the softening voltage of the respective contact material (< approx. 80mV) and the current stays below 10mA. Because of this low electrical load the switching occurs without any electrical discharge and also without any significant thermal stress on the contact spot. The main influences on the contact behavior are therefore chemical and mechanical in nature, such as contamination, and dust or abrasion particles for-med on the contact surfaces. The required high reliability can only be reached by using highly corrosion resistant contact materials. Since dust particle contamina-tions play a major role in determining the failure rate of these contacts, double (bifurcated) or multiple contacts are used frequently.

- Low Level Contacts

In this load range the voltage is between the softening and melting voltage of the contact material and the current is below 10mA. Because of the higher voltage compared to dry circuits a temperature induced softening of the contacting surface area occurs which increases the contacting area. Besides high corrosion resistance a higher hardness of the contact materials is required for this load range.

- Intermediate Level Contacts

This load range is characterized by a voltage below the minimum arc voltage and a current below 300mA. In this range discharges occur between the contacts which can electrically or thermally destroy at least partially contamination layers on the contact surfaces. At lower electrical load organic films may not be thermally destroyed completely which may lead to a steep increase in contact resistance. In DC circuits short arcs may result in material transfer. Contact materials for this load range need to be resistant against corrosion and the tendency to material transfer.

- Low Power (Load) Contacts

The main characteristic of this load range is the presence of stable electrical arcs. Caused by the interaction between contact material and electrical arcs the electrical life of contacts is limited by arc erosion or material transfer and in the case of higher make currents also by weld failures. For contact material selection the type of electrical load, i.e. resistive, inductive, capacitive, motor load, which determine the time function of the electrical current, is most critical.

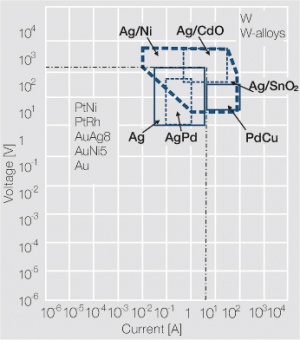

Figure 2 Fig. 6.2 gives an overview for commonly used electrical contact materials for different load ranges in switches used in the information technology up to the transition range towards power switching applications. The ranges are illustrated as a function of switching current and voltage.

For lower electrical loads mainly high precious materials based on Au and Pt are used because of their high corrosion resistance, the latter materials however used only in limited quantities because of the high price of platinum metals. Ag based materials cover the medium load range and are alloyed with Pd for currents <1A and voltages > 24V, and for loads above these levels Ag composite materials with additions of Ni, or the metal oxides SnO2, ZnO, or CdO are used. While the Pd addition reduces the silver sulfide formation in sulfur containing environments, adding metal oxides increases the resistance against welding and arc erosion at higher make currents. At high switching currents and switching frequency tungsten containing contacts are used, mainly as switching pre-contacts which absorb the electrical arcs at high make and break currents while parallel contacts mainly produced from silver containing materials such as AgNi0.15 (Fine-Grain Silver) are employed for current carrying in the closed condition.

Primarily the specific stresses on the contact assemblies must be considered during the selection of contact materials:

- During make of bouncing contacts mechanical wear, arc erosion, and material transfer occur, the latter mostly in DC switching circuits.

- In the closed condition the value and consistency of the contact resistance must be considered. Both are affected by the resistance to corrosion and changes in composition caused by the effects of arcing.

- During off-switching (break) the frictional wear leads to material loss; besides this material transfer and arc erosion effect contact life.