Difference between revisions of "Tungsten and Molybdenum Based Materials"

(→Silver–Molybdenum (SILMODUR) Materials) |

(→Silver–Tungsten (SIWODUR) Materials) |

||

| Line 12: | Line 12: | ||

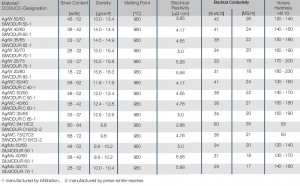

tungsten metal ''(Table 2.36)''. The manufacturing of materials with typically 50-80 wt% tungsten is performed by the powder metallurgical processes of | tungsten metal ''(Table 2.36)''. The manufacturing of materials with typically 50-80 wt% tungsten is performed by the powder metallurgical processes of | ||

liquid phase sintering or by infiltration. Particle size and shape of the starting powders are determining the micro structure and the contact specific properties of this material group ''(Figs. 2.134 and 2.135) (Table 2.37)''. | liquid phase sintering or by infiltration. Particle size and shape of the starting powders are determining the micro structure and the contact specific properties of this material group ''(Figs. 2.134 and 2.135) (Table 2.37)''. | ||

| − | |||

| − | |||

During repeated switching under arcing loads tungsten oxides and mixed oxides (silver tungstates – Ag<sub>2</sub> WO<sub>4</sub> ) are formed on the Ag/W surface creating 2 4 poorly conducting layers which increase the contact resistance and by this the temperature rise during current carrying. Because of this fact the Ag/W is paired in many applications with Ag/C contact parts. | During repeated switching under arcing loads tungsten oxides and mixed oxides (silver tungstates – Ag<sub>2</sub> WO<sub>4</sub> ) are formed on the Ag/W surface creating 2 4 poorly conducting layers which increase the contact resistance and by this the temperature rise during current carrying. Because of this fact the Ag/W is paired in many applications with Ag/C contact parts. | ||

Revision as of 19:07, 17 February 2014

Contents

Tungsten and Molybdenum (Pure Metals)

Tungsten is characterized by its advantageous properties of high melting and boiling points, sufficient electrical and thermal conductivity and high hardness and density (Table 2.35). It is mainly used in the form of brazed contact tips for switching duties that require a rapid switching sequence such as horn contacts for cars and trucks.

Molybdenum has a much lesser importance as a contact material since it is less resistant against oxidation than tungsten. Both metals are however used in large amounts as components in composite materials with silver and copper.

Table 2.35: Mechanical Properties of Tungsten and Molybdenum

Material | Micro Structure Condition | Vickers Hardness HV 10 | Tensile Strength [MPa] |

Wolfram | Lightly worked structure (wire and strip > 1.0 mm thick) Strongly worked structure (wire and strip < 1.0 mm thick) Re-crystallized structure | 300 - 500 500 - 750 360 | 1000 - 1800 1500 - 5000 1000 - 1200 |

Molybdän | Lightly worked structure (wire and strip > 1.0 mm thick) Strongly worked structure (wire and strip < 1.0 mm thick) Re-crystallized structure | 140 - 320 260 - 550 140 - 160 | 600 - 1100 800 - 2500 600 - 900 |

Silver–Tungsten (SIWODUR) Materials

Ag/W (SIWODUR) contact materials combine the high electrical and thermal conductivity of silver with the high arc erosion resistance of the high melting tungsten metal (Table 2.36). The manufacturing of materials with typically 50-80 wt% tungsten is performed by the powder metallurgical processes of liquid phase sintering or by infiltration. Particle size and shape of the starting powders are determining the micro structure and the contact specific properties of this material group (Figs. 2.134 and 2.135) (Table 2.37).

During repeated switching under arcing loads tungsten oxides and mixed oxides (silver tungstates – Ag2 WO4 ) are formed on the Ag/W surface creating 2 4 poorly conducting layers which increase the contact resistance and by this the temperature rise during current carrying. Because of this fact the Ag/W is paired in many applications with Ag/C contact parts.

Silver–tungsten contact tips are used in a variety of shapes and are produced for the ease of attachment with a fine silver backing layer and quite often an additional thin layer of a brazing alloy. The attachment to contact carriers is usually done by brazing, but also by direct resistance welding for smaller tips.

Ag/W materials are mostly used as the arcing contacts in disconnect switches for higher loads and as the main contacts in small and medium duty power switches and industrial circuit breakers (Table 2.38). In north and south america they are also used in large volumes in miniature circuit breakers of small to medium current ratings in domestic wiring as well as for commercial power distribution.

Silver–Tungsten Carbide (SIWODUR C) Materials

This group of contact materials contains the typically 40-65 wt-% of the very hard and erosion wear resistant tungsten carbide and the high conductivity silver (Fig. 2.135) (Table 2.36). Compared to Ag/W the Ag/WC (SIWODUR C) materials exhibit a higher resistance against contact welding (Table 2.37). The rise in contact resistance experienced with Ag/W is less pronounced in Ag/WC because during arcing a protective gas layer of CO is formed which limits the reaction of oxygen on the contact surface and therefore the formation of metal oxides.

Higher requirements on low temperature rise can be fulfilled by adding a small amount of graphite which however increases the arc erosion. Silver–tungsten carbide–graphite materials with for example 27 wt% WC and 3 wt% graphite or 16 wt% WC and 2 wt% graphite are manufactured using the single tip press-sinter-repress (PSR) process (Fig. 2.136).

The applications of Ag/WC contacts are similar to those for Ag/W (Table 2.38).

Silver–Molybdenum (SILMODUR) Materials

Ag/Mo materials with typically 50-70 wt% molybdenum are usually produced by the powder metallurgical infiltration process (Fig. 2.137) (Table 2.36). Their contact properties are similar to those of Ag/W materials (Table 2.37). Since the molybdenum oxide is thermally less stable than tungsten oxide the self-cleaning effect of Ag/Mo contact surface during arcing is more pronounced and the contact resistance remains lower than that of Ag/W. The arc erosion resistance of Ag/Mo however is lower than the one for Ag/W materials. The main applications for Ag/Mo contacts are in equipment protecting switching devices (Table 2.38).

Fig. 2.134: Micro structure of Ag/W 25/75

Fig. 2.135: Micro structure of Ag/WC 50/50

Fig. 2.136: Micro structure of Ag/WC27/C3

Fig. 2.137: Micro structure of Ag/Mo 35/65

Table 2.36: Physical Properties of Contact Materials Based on Silver–Tungsten (SIWODUR),

Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)

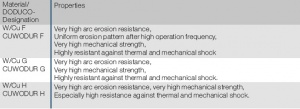

Table 2.37: Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)

Material/ DODUCO- Designation | Properties |

Silver-Tungsten SIWODUR Silver-tungsten carbide SIWODUR C | Tendency to weld at high make currents in symmetrical pairing, Higher contact resistance and higher temperature rise over increased number of operations through tungsten oxide and tungstate formation, especially for Ag/W, High welding tendency of closed contacts during short circuit, Very high arc erosion resistance, poor arc moving properties, High hardness and low formability, Easy to braze and weld through Ag enriched backing layer |

Silver-Tungsten Carbide plus Grafit SIWODUR C Plus | Low contact resistance and low temperature rise through graphite addition, Lower tendency to contact welding, Lower arc erosion resistance than Ag/W |

Silver-Molybdenum SILMODUR | Better contact resistance stability due to less stable surface layers, Lower arc erosion resistance than Ag/W |

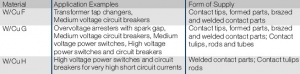

Table 2.38: Application Examples and Forms of Supply for Contact Materials Based on Silver–Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)

Copper–Tungsten (CUWODUR) Materials

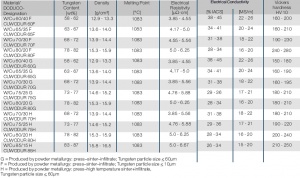

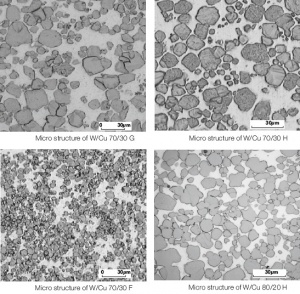

Copper–tungsten (CUWODUR) materials with typically 50-85 wt% tungsten are produced by the infiltration process with the tungsten particle size selected according to the end application (Figs. 2.138 – 2.141) (Table 2.39). To increase the wettability of the tungsten skeleton by copper a small amount of nickel < 1 wt% is added to the starting powder mix.

W/Cu materials exhibit a very high arc erosion resistance (Table 2.40). Compared to silver–tungsten materials they are however less suitable to carry permanent current.

With a solid tungsten skeleton as it is the case for W/C infiltrated materials with 70-85 wt% tungsten the lower melting component copper melts and vaporizes in the intense electrical arc. At the boiling point of copper (2567°C) the still solid tungsten is efficiently “cooled” and remains pretty much unchanged.

During very high thermal stress on the W/Cu contacts, for example during short circuit currents > 40 kA the tungsten skeleton requires special high mechanical strength. For such applications a high temperature sintering of tungsten from selected particle size powder is applied before the usual infiltration with copper (example: CUWODUR H).

For high voltage load switches the most advantageous contact system consists of a contact tulip and a contact rod. Both contact assemblies are made usually from the mechanically strong and high conductive CuCrZr material and W/Cu as the arcing tips. The thermally and mechanically highly stressed attachment between the two components is often achieved by utilizing electron beam welding or capacitor discharge percussion welding. Other attachment methods include brazing and cast-on of copper followed by cold forming steps to increase hardness and strength.

The main application areas for CUWODUR materials are as arcing contacts in load and high power switching in medium and high voltage switchgear as well as electrodes for spark gaps and over voltage arresters (Table 2.41).

Table 2.39: Physical Properties of Copper–Tungsten (CUWODUR) Contact Materials

Fig. 2.139: Micro structure of W/Cu 70/30 G Fig. 2.140: Micro structure of W/Cu 70/30 H

Fig. 2.138: Micro structure of W/Cu 70/30 F Fig. 2.141: Micro structure of W/Cu 80/20 H

Table 2.40: Contact and Switching Properties of Copper–Tungsten (CUWODUR) Contact Materials

Table 2.41: Application Examples and Forms of Supply for Tungsten– Copper (CUWODUR) Contact Materials