Difference between revisions of "High Electrical Loads"

Doduco Admin (talk | contribs) (→High Electrical Loads) |

Doduco Admin (talk | contribs) (→High Electrical Loads) |

||

| Line 3: | Line 3: | ||

At high electric loads that usually occur in power engineering devices, the switching phenomena are mostly related to arc formation. For most applications, the management of the switching arc is the key problem. Depending on the device, type different requirements are dominant which influence the selection of the contact material. Similar to those in communications engineering, issues related to the switching characteristics and current path have to be considered. | At high electric loads that usually occur in power engineering devices, the switching phenomena are mostly related to arc formation. For most applications, the management of the switching arc is the key problem. Depending on the device, type different requirements are dominant which influence the selection of the contact material. Similar to those in communications engineering, issues related to the switching characteristics and current path have to be considered. | ||

<figure id="fig:Typical application ranges for contact materials"> | <figure id="fig:Typical application ranges for contact materials"> | ||

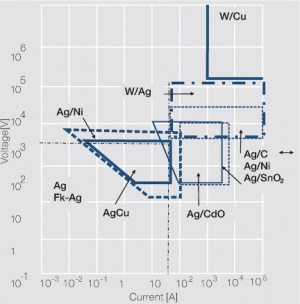

| − | [[File:Typical application ranges for contact materials.jpg|right|thumb|Typical application ranges for contact materials in power engineering switching devices as a function of switching current and voltage]] | + | [[File:Typical application ranges for contact materials.jpg|right|thumb|Figure 1: Typical application ranges for contact materials in power engineering switching devices as a function of switching current and voltage]] |

</figure> | </figure> | ||

<figure id="fig:Application ranges for contact materials"> | <figure id="fig:Application ranges for contact materials"> | ||

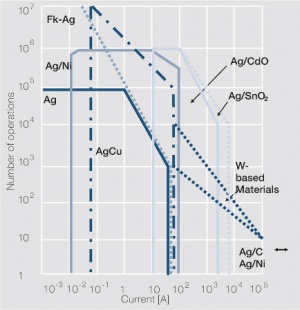

| − | [[File:Application ranges for contact materials.jpg|right|thumb|Application ranges for contact materials in power engineering switching devices as a function of switching current and numbers of operation]] | + | [[File:Application ranges for contact materials.jpg|right|thumb|Figure 2: Application ranges for contact materials in power engineering switching devices as a function of switching current and numbers of operation]] |

</figure> | </figure> | ||

*'''Make operation''' <br />Make erosion caused by pre-close and bounce arcs <br />Welding mainly during bounce arc <br />Mechanical wear mainly through bounce and relative motion<br/> | *'''Make operation''' <br />Make erosion caused by pre-close and bounce arcs <br />Welding mainly during bounce arc <br />Mechanical wear mainly through bounce and relative motion<br/> | ||

Revision as of 08:56, 4 January 2023

High Electrical Loads

At high electric loads that usually occur in power engineering devices, the switching phenomena are mostly related to arc formation. For most applications, the management of the switching arc is the key problem. Depending on the device, type different requirements are dominant which influence the selection of the contact material. Similar to those in communications engineering, issues related to the switching characteristics and current path have to be considered.

- Make operation

Make erosion caused by pre-close and bounce arcs

Welding mainly during bounce arc

Mechanical wear mainly through bounce and relative motion

- Current carrying through closed contacts

Increased contact resistance and temperature rise

during nominal load

Welding through high contact resistance during overload and short circuit load

Welding during dynamic separation of the contacts with arcing

- Break operation

Arc erosion during opening

Arc movement

Arc extinguishing

Mechanical wear

The typical application ranges for different contact materials in devices for power engineering are illustrated in Figure 1 and Figure 2. In the lower load ranges, mostly silver and fine grain silver (AgNi0.15) are used because of their high electrical and thermal conductivity. With increasing currents, the more arc erosion resistant AgCu alloy materials are used. For the medium current range up to 100A Ag/Ni composite materials are advantageous because of their lower and consistent contact resistance and their favorable re-solidification properties. If higher welding and at the same time arc erosion resistance are required, such as for example in motor contactors for switching currents up to 5000A, silver – metal oxide materials are superior. In protective switches (mainly circuit breakers) which are required to handle high short circuit energies. Asymmetrical contact pairings are used, where the fixed contact is made from Ag/C materials and the moving ones consist, depending on the device characteristics of Cu, Ag/Ni, or Ag/W. For UL rated and certified circuit breakers (UL = Underwriters Laboratories) which are mainly used in North American power distribution networks, symmetrical pairings of Ag/W or Ag/WC are the preferred contact materials.

For very high loads in main power switches and power circuit breakers for medium and high voltage power engineering applications, the most suitable materials are tungsten based infiltration materials such as W/Cu.