Difference between revisions of "Application Properties for the Selection of Copper Alloys"

Doduco Admin (talk | contribs) (→Fatigue Strength) |

Doduco Admin (talk | contribs) (→Bendability) |

||

| Line 28: | Line 28: | ||

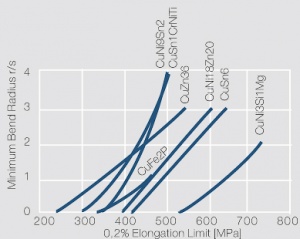

The measure for bendability of a strip material is the smallest possible bending radius r of a sample piece of given material thickness s without appearance of surface cracking. Bending tests are performed as either 90 degree bends according to ISO 7438 or as defined forth-and-back bending. The bendabilty of naturally hard copper alloys is significantly better perpendicular to the rolling direction than parallel to it [[#figures10|(Figs. 4 – 7)]]<!--(Figs. 5.41 and 5.42)-->. | The measure for bendability of a strip material is the smallest possible bending radius r of a sample piece of given material thickness s without appearance of surface cracking. Bending tests are performed as either 90 degree bends according to ISO 7438 or as defined forth-and-back bending. The bendabilty of naturally hard copper alloys is significantly better perpendicular to the rolling direction than parallel to it [[#figures10|(Figs. 4 – 7)]]<!--(Figs. 5.41 and 5.42)-->. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<div class="multiple-images"> | <div class="multiple-images"> | ||

<figure id="fig:Smallest possible bend radii for 90 bends as function"> | <figure id="fig:Smallest possible bend radii for 90 bends as function"> | ||

| − | [[File:Smallest possible bend radii for 90 bends as function.jpg|right|thumb|Smallest possible bend radii for 90° bends as a function of the 0.2% yield strength R<sub>p0.2</sub> – bend line perpendicular to the rolling direction (Wieland)]] | + | [[File:Smallest possible bend radii for 90 bends as function.jpg|right|thumb|Figure 4: Smallest possible bend radii for 90° bends as a function of the 0.2% yield strength R<sub>p0.2</sub> – bend line perpendicular to the rolling direction (Wieland)]] |

</figure> | </figure> | ||

<figure id="fig:Smallest possible bend radii as a functionbend line parallel to the rolling direction"> | <figure id="fig:Smallest possible bend radii as a functionbend line parallel to the rolling direction"> | ||

| − | [[File:Smallest possible bend radii as a functionbend line parallel to the rolling direction.jpg|right|thumb|Smallest possible bend radii for 90° bends as a function of the 0.2% yield strength R<sub>p0.2</sub> – bend line parallel to the rolling direction (Wieland)]] | + | [[File:Smallest possible bend radii as a functionbend line parallel to the rolling direction.jpg|right|thumb|Figure 5: Smallest possible bend radii for 90° bends as a function of the 0.2% yield strength R<sub>p0.2</sub> – bend line parallel to the rolling direction (Wieland)]] |

</figure> | </figure> | ||

</div> | </div> | ||

Revision as of 07:17, 3 January 2023

Important for the usage as spring contact components are, besides mechanical strength and electrical conductivity, mainly the typical spring properties such as the maximum spring bending limit and the fatigue strength as well as the bendability. During severe thermal stressing the behavior of spring materials is determined by their softening and relaxation. The following briefly describes these material properties.

Contents

Spring Bending Limit

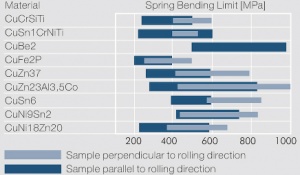

The spring bending limit is defined as the boundary condition under which a standardized spring sample retains a deformation of 0.05 mm after initial bend stressing and subsequent force removal. The measurement is performed according to the standard EN 12384. The spring bending limit is strongly dependent on the direction of stressing with regard to the strip rolling orientation (Figure 1). Higher values are obtained, if bending is perpendicular to the rolling direction, as compared to parallel. This has to be considered when designing contact springs.

Fatigue Strength

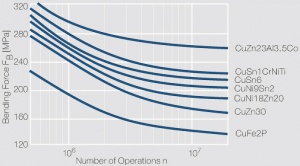

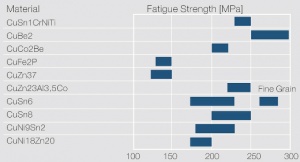

The fatigue strength is a measure of maximum alternating bending force, symmetrical to the zero position, which a sample – for example a relay spring – can be exposed to for an “unlimited” number of cycles without breaking. (Rule of thumb: Fatigue strength = 1/3 of Tensile strength). The measurement is carried out with so-called Wöhler diagrams. With increasing bending force the number of alternating cycles before breaking decreases. Above 10 cycles the influence of further cycling numbers becomes insignificant and therefore the force value reaching 2x10 cycles can be used to define the fatigue strength. The multi-component alloys CuZn23Al3.5Co and CuSn1CrNiTi show high values of fatigue strength while CuFe2P and CuZn30 exhibit low ones (Figs. 2 – 3).

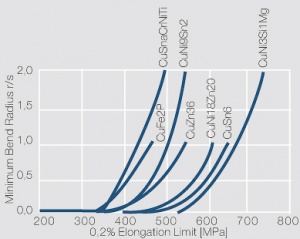

Bendability

The measure for bendability of a strip material is the smallest possible bending radius r of a sample piece of given material thickness s without appearance of surface cracking. Bending tests are performed as either 90 degree bends according to ISO 7438 or as defined forth-and-back bending. The bendabilty of naturally hard copper alloys is significantly better perpendicular to the rolling direction than parallel to it (Figs. 4 – 7).

Softening Behavior

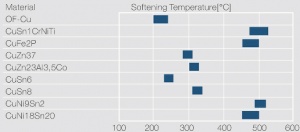

Through thermal activation at elevated temperatures the original mechanical material strength achieved by cold working or precipitation hardening can be reversed completely. The start of softening is mostly defined as the temperature at which a 10% reduction of mechanical strength is reached. It is dependent on the degree of initial cold working and the annealing temperature and time. At higher initial degrees of cold forming, the softening temperature is lowered. As expected, the softening temperature for pure copper is rather low. CuNi9Sn2 and CuSn1CrNiTi exhibit high softening temperatures Figure 6.

Relaxation Behavior

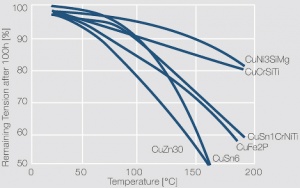

Tension relaxation is defined as the loss of tension of an elastically stressed material as a function of time and temperature. The causes for the relaxation are thermally activated processes which are comparable to creep behavior. As a measure for the relaxation the percentage decrease in the bending tension compared to the initial one is used. Temperature increase is a stronger influencing factor on the relaxation of the spring force than increasing operating times. Through suitable annealing processes the relaxation degree can be significantly reduced. For the measurement of tension relaxation, different test procedures are used, based on the ASTM E-32-86.

Figure 7 illustrates the different relaxation behavior of some copper alloys. Good behavior is shown for CuNi3Si1Mg and CuCrSiTi while CuZn30 and CuSn6 exhibit a less favorable relaxation tendency.