Difference between revisions of "Precipitation Hardening Copper Alloys"

(→5.1.6.2.3 Copper-Chromium-Zirconium Alloys) |

|||

| Line 316: | Line 316: | ||

The earlier used CuCr and CuZr materials have been partially replaced over the years by the capitation hardening three materials alloy CuCr1Zr. This material exhibits high mechanical strength at elevated temperatures and good oxidation resistance as well as high softening temperatures. In its hardened condition CuCr1Zr has also a high electrical conductivity <xr id="fig:Softening of CuCr1Zr after 1hr annealing"/> (Bild 5.37). Their usage extends from mechanically and thermally highly stressed parts such as contact tulips in high voltage switchgear to electrodes for resistance welding. | The earlier used CuCr and CuZr materials have been partially replaced over the years by the capitation hardening three materials alloy CuCr1Zr. This material exhibits high mechanical strength at elevated temperatures and good oxidation resistance as well as high softening temperatures. In its hardened condition CuCr1Zr has also a high electrical conductivity <xr id="fig:Softening of CuCr1Zr after 1hr annealing"/> (Bild 5.37). Their usage extends from mechanically and thermally highly stressed parts such as contact tulips in high voltage switchgear to electrodes for resistance welding. | ||

| − | <xr id="fig:Copper corner of the copper zirconium for up to 0.5-wt zirconium"/> Fig. 5.36: Copper corner of the copper- zirconium for up to 0.5 wt% zirconium | + | <xr id="fig:Copper corner of the copper zirconium for up to 0.5-wt zirconium"/> Fig. 5.36: Copper corner of the copper- zirconium for up to 0.5 wt% zirconium |

| − | <xr id="fig:Softening of CuCr1Zr after 1hr annealing"/> Fig. 5.37: Softening of CuCr1Zr after 1 hr annealing and after 90% cold working | + | <xr id="fig:Softening of CuCr1Zr after 1hr annealing"/> Fig. 5.37: Softening of CuCr1Zr after 1 hr annealing and after 90% cold working |

<div class="multiple-images"> | <div class="multiple-images"> | ||

Revision as of 12:09, 12 May 2014

Besides the naturally hard copper materials precipitation hardening copper alloys play also an important role as carrier materials for electrical contacts. By means of a suitable heat treatment finely dispersed precipitations of a second phase can be achieved which increase the mechanical strength of these copper alloys significantly.

Contents

5.1.6.1 Copper-Beryllium Alloys (Beryllium Bronze)

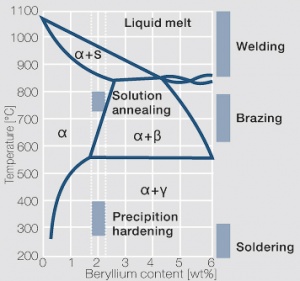

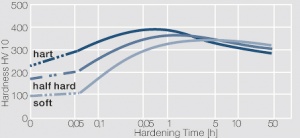

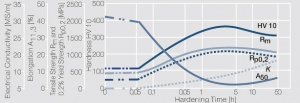

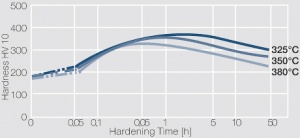

The cause for precipitation hardening of CuBe materials is the rapidly diminishing solubility of beryllium in copper as temperature decrease. As the phase diagram for CuBe shows, 2.4 wt% of Be are soluble in Cu at 780°C Figure 1 (Fig. 5.28). In this temperature range annealed CuBe alloys are homogeneous(solution annealing). The homogeneous state can be frozen through rapid cooling to room temperature (quenching). Through a subsequent annealing at 325°C the desired precipitation hardening is achieved which results in a significant increase in mechanical strength and electrical conductivity of CuBe Table 1 (Tab. 5.17). The final strength and hardness values depend on the annealing temperature and time as well as on the initial degree of cold working Table 2 (Table 5.18) and (Figs. 43 – 75)(Figs. 5.29 - 5.31).

As precipitation hardening alloys CuBe materials, mainly CuBe2 and CuBe1.7 have gained broad usage as current carrying contact springs because of their outstanding mechanical properties. Besides these CuCo2Be and CuNi2Be, which have medium mechanical strength and a relatively high electrical

conductivity, are also used as contact carrier materials. After stamping and forming into desired contact configurations these CuBe materials are then precipitation hardened. CuBe alloys are available as semi-finished materials in a variety of cold work conditions. They can also be supplied and used in the already precipitation hardened condition without significant strength losses. In this case the hardening was already performed at the alloy producer.

Since Beryllium is rated as a carcinogen by the European regulation EU-67/548, it has been tried to reach the application properties of the well established CuBe1.7 and CuBe2 alloys with a lower Be content. The development efforts for alternate precipitation hardening materials without toxic and declaration requiring additive materials, for example CuNiCoSi, are aimed at the replacement of CuBe.

Figure 1 Fig. 5.28: Phase diagram of copper- beryllium with temperature ranges for brazing and annealing treatments

Figure 2 Fig. 5.29: Precipitation hardening of CuBe2 at 325°C after different cold working

Figure 3 Fig. 5.30: Precipitation hardening of CuBe2 (soft) at 325°C

Figure 4 Fig. 5.31: Precipitation hardening of CuBe2 (half hard) at different annealing temperatures

| Material Designation EN UNS |

Composition [wt%] |

Density [g/cm3] |

Electrical Conductivity |

Electrical Resistivity [μΩ·cm] |

Thermal Conductivity [W/(m·K)] |

Coeff. of Linear Thermal Expansion [10-6/K] |

Modulus of Elasticity [GPa] |

Softening Temperature (approx. 10% loss in strength) [°C] |

Melting Temp Range [°C] | |

|---|---|---|---|---|---|---|---|---|---|---|

| [MS/m] | [% IACS] | |||||||||

| CuBe1.7 CW100C C17000 |

Be 1.6 - 1.8 Co 0.3 Ni 0.3 Cu Rest |

8.4 | 8 - 9a 12 - 13b 11c |

14 - 16 21 - 22 19 |

11 - 12.5a 7.7 - 8.3b 9.1c |

110 | 17 | 125a 135b |

ca. 380 | 890 - 1000 |

| CuBe2 CW101C C17200 |

Be 1.8 - 2.1 Co 0.3 Ni 0.3 Cu Rest |

8.3 | 8 - 9a 12 - 13b 11c |

14 - 16 21 - 22 19 |

11 - 12.5a 7.7 - 8.3b 9.1c |

110 | 17 | 125a 135b |

ca. 380 | 870 - 980 |

| CuCo2Be CW104C C17500 |

Co 2.0 - 2.8 Be 0.4 - 0.7 Ni 0.3 Cu Rest |

8.8 | 11 - 14a 25 - 27b 27 - 34c |

19 - 24 43 - 47 47 - 59 |

7.1 - 9.1a 3.7 - 4.0b 2.9c |

210 | 18 | 131a 138b |

ca. 450 | 1030 - 1070 |

| CuNi2Be CW110C C17510 |

Ni 1.4 - 2.2 Be 0.2 - 0.6 Co 0.3 Cu Rest |

8.8 | 11 - 14a 25 - 27b 27 - 34c |

19 - 24 43 - 47 47 - 59 |

7.1 - 9.1a 3.7 - 4.0b 2.9c |

230 | 18 | 131a 138b |

ca. 480 | 1060 - 1100 |

asolution annealed, and cold rolled

bsolution annealed, cold rolled, and precipitation hardened

csolution annealed, cold rolled, and precipitation hardened at mill (mill hardened)

| Material | Hardness Condition |

Tensile Strength Rm [MPa] |

0,2% Yield Strength Rp02 [MPa] |

Elongation A50 [%] |

Vickers Hardness HV |

Bend Radius1) perpendicular to rolling direction |

Bend Radius1) parallel to rolling direction |

Spring Bending Limit σFB [MPa] |

Spring Fatigue Limit σBW [MPa] |

|---|---|---|---|---|---|---|---|---|---|

| CuBe1,7 | R 390a R 680a R 1030b R 1240b R 680c R 1100c |

380 -520 680 - 820 1030 - 1240 1240 - 1380 680 - 750 1100 - 1200 |

≥ 180 ≥ 600 ≥ 900 ≥ 1070 ≥ 480 ≥ 930 |

35 2 3 1 18 3 |

80 - 135 210 - 250 330 - 380 360 - 420 220 - 350 330 - 370 |

0 x t 1 x t 1 x t 1 x t 6 x t |

0 x t 3 x t 1.5 x t 1 x t 10 x t |

700 1000 390 790 |

260 280 260 |

| CuBe2 | R 410a R 690a R 1140b R 1310b R 690c R 1200c |

410 -540 690 - 820 1140 - 1310 1310 - 1480 690 - 760 1200 - 1320 |

≥ 190 ≥ 650 ≥ 1000 ≥ 1150 ≥ 480 ≥ 1030 |

35 2 3 1 18 3 |

90 - 140 215 - 260 350 - 400 380 - 450 220 - 250 360 - 410 |

0 x t 1 x t 1 x t 5 x t |

0 x t 3 x t 1.5 x t 10 x t |

800 1040 400 900 |

270 300 280 |

| CuCo2Be CuNi2Be |

R 250a R 550a R 650b R 850b R 520c |

250 - 380 550 - 700 650 - 820 850 - 1000 520 - 620 |

≥ 140 ≥ 450 ≥ 520 ≥ 750 ≥ 340 |

20 2 10 1 5 |

60 - 90 160 - 200 195 - 230 240 - 290 150 - 180 |

0 x t 3 x t 1 x t 3 x t 1 x t |

0 x t 1 x t 3.5 x t 1 x t |

360 650 300 |

220 250 210 |

1) t: Strip thickness max. 0.5 mm

asolution annealed, and cold rolled

bsolution annealed, cold rolled, and precipitation hardened

csolution annealed, cold rolled, and precipitation hardened at mill (mill hardened)

5.1.6.2 Other Precipitation Hardening Copper Alloys

5.1.6.2.1 Copper-Chromium Alloys

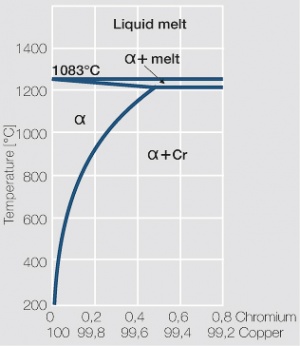

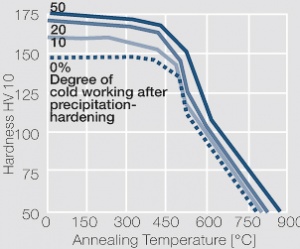

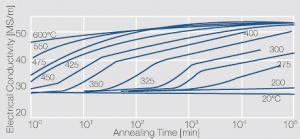

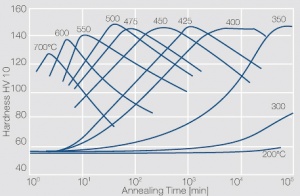

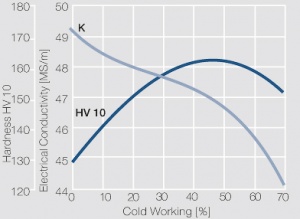

As the phase diagram shows, copper-chromium has a similar hardening profile compared to CuBe Figure 5(Fig. 5.32). In the hardened stage CuCr has limitations to work hardening. Compared to copper it has a better temperature stability with good electrical conductivity. Hardness and electrical conductivity as a function of cold working and precipitation hardening conditions are illustrated in (Figs. 6 – 9) Figs. 5.33-5.35, Table 3 (Tables 5.19) and Table 4 (Tab. 5.20).

Copper-chromium materials are especially suitable for use as electrodes for resistance welding. During brazing the loss in hardness is limited if low melting brazing alloys and reasonably short heating times are used.

Figure 5 Fig. 5.32: Copper corner of the copper-chromium phase diagram for up to 0.8 wt% chromium

Figure 6 Fig. 5.33: Softening of precipitation-hardened and subsequently cold worked CuCr1 after 4hrs annealing

Figure 7 Fig. 5.34 a: Electrical conductivity of precipitation hardened CuCr 0.6 as a function of annealing conditions

Figure 8 Fig. 5.34 b: Hardness of precipitation hardened CuCr 0.6 as a function of annealing conditions

Figure 9 Fig. 5.35: Electrical conductivity and hardness of precipitation hardened CuCr 0.6 after cold working

| Material Designation EN UNS |

Composition [wt%] |

Density [g/cm3] |

Electrical Conductivity |

Electrical Resistivity [μΩ·cm] |

Thermal Conductivity [W/(m·K)] |

Coeff. of Linear Thermal Expansion [10-6/K] |

Modulus of Elasticity [GPa] |

Softening Temperature (approx. 10% loss in strength) [°C] |

Melting Temp Range [°C] | |

|---|---|---|---|---|---|---|---|---|---|---|

| [MS/m] | [% IACS] | |||||||||

| CuCr | Cr 0.3 - 1.2 Cu Rest |

8.89 | 26a 48b |

45a 83b |

3.8a 2.1b |

170a 315b |

17 | 112 | ca. 450 | 980 - 1080 |

| CuZr | Zr 0.1 - 0.3 Cu Rest |

8.9 | 35a 52b |

60a 90b |

2.9a 1.9b |

340a | 16 | 135 | ca. 500 | 1020 - 1080 |

| CuCr1Zr CW106C C18150 |

Cr 0.5 - 1.2 Zr 0.03 - 0.3 Cu Rest |

8.92 | 20a 43b |

34a 74b |

5.0a 2.3b |

170a 310 - 330b |

16 | 110a 130b |

ca. 500 | 1070 - 1080 |

asolution annealed, and cold rolled

bsolution annealed, cold rolled, and precipitation hardened

Material | Hardness Condi- tion | Tensile Strength Rm [MPa] | 0,2% Yield Strength Rp02 [MPa] | Elongation A50 [%] | Vickers Hardness HV | Spring Bending Limit FFB [MPa] |

|---|---|---|---|---|---|---|

CuCr | R 230a R 400a R 450b R 550b | > 230 > 400 > 450 > 550 | > 80 > 295 > 325 > 440 | 30 10 10 8 | > 55 > 120 > 130 > 150 | 350 |

CuZr | R 260a R 370a R 400b R 420b | > 260 > 370 > 400 > 420 | > 100 > 270 > 280 > 400 | 35 12 12 10 | > 55 > 100 > 105 > 115 | 280 |

CuCr1Zr | R 200a R 400b R 450b | > 200 > 400 > 450 | > 60 > 210 > 360 | 30 12 10 | > 70 > 140 > 155 | 420 |

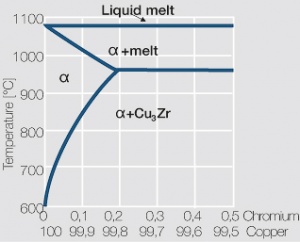

5.1.6.2.2 Copper-Zirconium Alloys

The solubility of Zirconium in copper is 0.15 wt% Zr at the eutectic temperature of 980°C Figure 10 (Fig. 5.36). Copper-zirconium materials have a similar properties spectrum compared to the one for copper-chromium materials. At room temperature the mechanical properties of copper-zirconium are less suitable than those of copper chromium, its temperature stability is however at least the same.

5.1.6.2.3 Copper-Chromium-Zirconium Alloys

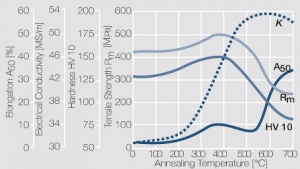

The earlier used CuCr and CuZr materials have been partially replaced over the years by the capitation hardening three materials alloy CuCr1Zr. This material exhibits high mechanical strength at elevated temperatures and good oxidation resistance as well as high softening temperatures. In its hardened condition CuCr1Zr has also a high electrical conductivity Figure 11 (Bild 5.37). Their usage extends from mechanically and thermally highly stressed parts such as contact tulips in high voltage switchgear to electrodes for resistance welding.

Figure 10 Fig. 5.36: Copper corner of the copper- zirconium for up to 0.5 wt% zirconium

Figure 11 Fig. 5.37: Softening of CuCr1Zr after 1 hr annealing and after 90% cold working