Difference between revisions of "Switching Contacts"

(→6.4.4 Switching Contacts) |

|||

| Line 3: | Line 3: | ||

<li>'''Effects during switching operations'''</li> | <li>'''Effects during switching operations'''</li> | ||

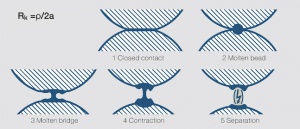

| − | <xr id="fig: | + | <xr id="fig:Contact_opening_with_arc_formation_schematic"/> Fig. 6.7: Contact opening with arc formation schematic |

<div class="multiple-images"> | <div class="multiple-images"> | ||

| − | <figure id=" | + | <figure id="Contact_opening_with_arc_formation_schematic"> |

[[File:Contact opening with arc formation schematic.jpg|left|thumb|<caption>Contact opening with arc formation (schematic)</caption>]] | [[File:Contact opening with arc formation schematic.jpg|left|thumb|<caption>Contact opening with arc formation (schematic)</caption>]] | ||

</figure> | </figure> | ||

| Line 14: | Line 14: | ||

<li>'''Influence of out-gasing from plastics'''</li> | <li>'''Influence of out-gasing from plastics'''</li> | ||

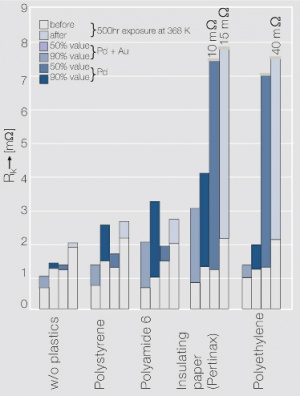

| − | <xr id="fig: | + | <xr id="fig:Histogram_of_the_contact_resistance_Rk"/> Fig. 6.9: Histogram of the contact resistance Rk of an electroplated palladium layer (3 μm) with and without hard gold flash plating (0.2 μm) after exposure with different plastic materials |

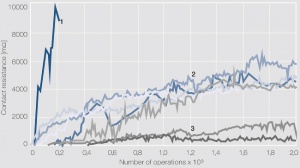

| − | <xr id="fig: | + | <xr id="fig:Contact resistance with exposure to out gasing from plastics"/> Fig. 6.10: Contact resistance with exposure to out gasing from plastics as a function of numbers of operations at 6 V<sub>DC</sub>,100 mA: 1 Silicon containing plastic; 2 Plastics with strongly out-gasing components; 3 Plastics with minimal out-gasing components |

<div class="multiple-images"> | <div class="multiple-images"> | ||

| − | <figure id="fig: | + | <figure id="fig:Histogram_of_the_contact_resistance_Rk"> |

[[File:Histogram of the contact resistance Rk.jpg|left|thumb|<caption>Histogram of the contact resistance R<sub>K</sub> of an electroplated palladium layer (3 μm) with and without hard gold flash plating (0.2 μm) after exposure with different plastic materials</caption>]] | [[File:Histogram of the contact resistance Rk.jpg|left|thumb|<caption>Histogram of the contact resistance R<sub>K</sub> of an electroplated palladium layer (3 μm) with and without hard gold flash plating (0.2 μm) after exposure with different plastic materials</caption>]] | ||

</figure> | </figure> | ||

| − | <figure id="fig: | + | <figure id="fig:Contact resistance with exposure to out gasing from plastics"> |

[[File:Contact resistance with exposure to out gasing from plastics.jpg|left|thumb|<caption>Contact resistance with exposure to out-gasing from plastics as a function of numbers of operations at 6 V<sub>DC</sub>,100 mA: 1 Silicon containing plastic; 2 Plastics with strongly out-gasing components; 3 Plastics with minimal out-gasing components</caption>]] | [[File:Contact resistance with exposure to out gasing from plastics.jpg|left|thumb|<caption>Contact resistance with exposure to out-gasing from plastics as a function of numbers of operations at 6 V<sub>DC</sub>,100 mA: 1 Silicon containing plastic; 2 Plastics with strongly out-gasing components; 3 Plastics with minimal out-gasing components</caption>]] | ||

</figure> | </figure> | ||

Revision as of 13:49, 14 May 2014

6.4.4 Switching Contacts

- Effects during switching operations

- Influence of out-gasing from plastics

- Influence of corrosive gases on the contact resistance

- Contact Phenomena under the influence of arcing Matertia

- Material transfer

- Arc erosion

- Contact welding

??? Fig. 6.7: Contact opening with arc formation schematic

Figure 2 Fig. 6.9: Histogram of the contact resistance Rk of an electroplated palladium layer (3 μm) with and without hard gold flash plating (0.2 μm) after exposure with different plastic materials

Figure 3 Fig. 6.10: Contact resistance with exposure to out gasing from plastics as a function of numbers of operations at 6 VDC,100 mA: 1 Silicon containing plastic; 2 Plastics with strongly out-gasing components; 3 Plastics with minimal out-gasing components

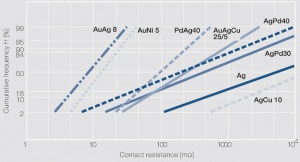

Figure 4 Fig. 6.11: Distribution of cumulative frequency H of the contact resistance for solid contact rivets after 10 days exposure in a three-component test environment with 400 ppb each of H2S, SO2 and NO2 at 25°C, 75% RH; Contact force 10cN; Measuring parameters: ≤ 40 mVDC,10 mA; Probing contact: Gold rivet

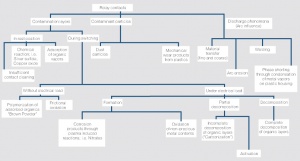

Fig. 6.8: Influences on contact areas in relays

Figure 5 Fig. 6.12: Material transfer under DC load a) Cathode; b) Anode.

Material: AgNi0.15; Switching parameters: 12VDC, 3 A, 2x106 operations

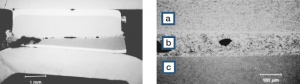

Figure 6 Fig. 6.13: Arc erosion of a Ag/SnO2 contact pair after extreme arcing conditions a) Overall view; b) Partial detail view

Figure 7 Fig. 6.14: Micro structure of a welded contact pair (Ag/SnO288/12 - Ag/CdO88/12) after extremely high current load. a) Ag/SnO288/12; b) Ag/CdO88/12