Difference between revisions of "General Rules for Dimensioning of Contacts"

From Electrical Contacts

(→6.4.6 General Rules for Dimensioning of Contacts) |

(→6.4.6 General Rules for Dimensioning of Contacts) |

||

| Line 73: | Line 73: | ||

|s<sub>min</sub> | |s<sub>min</sub> | ||

| | | | ||

| − | |0.3 mm | + | |≈ 0.3 mm |

|} | |} | ||

*'''Head diameter for electrical loads''' | *'''Head diameter for electrical loads''' | ||

Revision as of 10:47, 2 April 2014

6.4.6 General Rules for Dimensioning of Contacts

- Recommended Minimum Contact Forces at Slightly Sliding Contact Make:

| Gold | 0.03 N |

| Silver | 0.1 N |

| Tungsten | 0.5 N |

- Contact Force Recommendations:

| Signal relays | ≥ 3 cN |

| AC power relays | ≥ 20 cN |

| Automotive relays | ≥ 20 cN |

| Motor switches (Contactors) (Silver – Metal oxide contacts) |

0.05 - 0.08 N/A |

| Power switches | 0.1 - 0.2 N/A |

| Connectors (Gold coating) |

≥ 30 cN/contact element |

| Connectors (Silver coating) |

≥ 50 cN/contact element |

| Connectors (Tin coating) |

≥ 1 N/contact element |

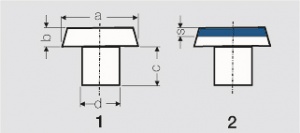

- General Rules for Dimensioning of Contact Rivets

| Dimensioning | Solid Rivets (1) | Composite Rivets (2) |

|---|---|---|

| a : d | 1.5 : 1 bis 2.5 : 1 | 2 : 1 bis 2.5 : 1 |

| a : b | 2.5 : 1 bis 10 : 1 | 3 : 1 bis 5 : 1 |

| c : b | ≥ 1 : 1 | ≥ 1 : 1 |

| b : s | ≥ 2 : 1 | |

| smin | ≈ 0.3 mm |

- Head diameter for electrical loads

For AC currents: approx. 1 – 1.5 A/mm² For 1 A min. 2 mm head diameter 10 A approx. 3 – 3.5 mm head diameter 20 A approx. 5 mm head diameter For DC currents: approx. 0.5 – 0.8 A/mm²

- Head radius R for electrical loads

for I < 1 A R 1,5 mm I = 6 A R 5 mm I = 10 A R 10 mm I = 20 A R 15 mm

- Failure Probability of Single and Double (Bifurcated) Contacts (according to Thielecke)

Fig. 6.18: Failure probability of a contact as a function of the voltage (according to Kirchdorfer); Ag/Ni10; 10 mA

Fig. 6.19: Failure probability of a contact as a function of the current (according to Kirchdorfer); Ag/Ni10; F = 0.45 N; U = 24 V