Difference between revisions of "Platinum Metal Based Materials"

Doduco Admin (talk | contribs) (→DEVELOP:ImageLIst) |

Doduco Admin (talk | contribs) (→DEVELOP:ImageLIst) |

||

| Line 24: | Line 24: | ||

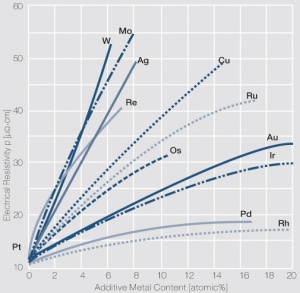

Fig. 2.25: Influence of 1-20 atom% of different additive metals on the electrical resistivity p of platinum (Degussa) | Fig. 2.25: Influence of 1-20 atom% of different additive metals on the electrical resistivity p of platinum (Degussa) | ||

| − | <xr id="fig: | + | <xr id="fig:Influence_of_1-20_atom%_of_different_additive_metals_on_the_electrical_resistivit_ p_of_platinum"/> |

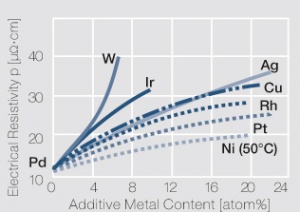

Fig. 2.26: Influence of 1-22 atom% of different additive metals on the electrical resistivity p of palladium | Fig. 2.26: Influence of 1-22 atom% of different additive metals on the electrical resistivity p of palladium | ||

| Line 30: | Line 30: | ||

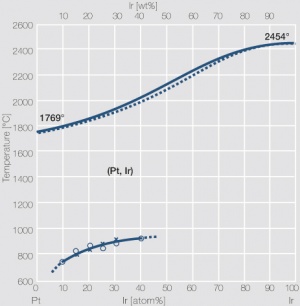

Fig. 2.27: Phase diagram of platinum-iridium | Fig. 2.27: Phase diagram of platinum-iridium | ||

| − | <xr id="fig: | + | <xr id="fig:Phase_diagram_of_platinum-nickel"/> |

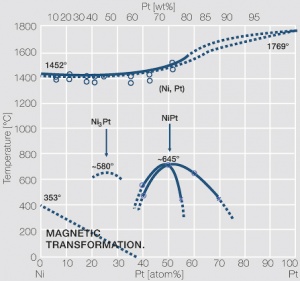

Fig. 2.28: Phase diagram of platinum-nickel | Fig. 2.28: Phase diagram of platinum-nickel | ||

| Line 36: | Line 36: | ||

Fig. 2.29: Phase diagram of platinum-tungsten | Fig. 2.29: Phase diagram of platinum-tungsten | ||

| − | <xr id="fig: | + | <xr id="fig:Phase_diagram_of_platinum-copper"/> |

Fig. 2.30: Phase diagram of palladium-copper | Fig. 2.30: Phase diagram of palladium-copper | ||

| − | <xr id="fig: | + | <xr id="fig:Strain_hardening_of_Pt_by_cold_working"/> |

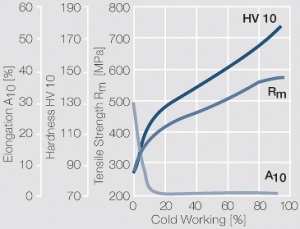

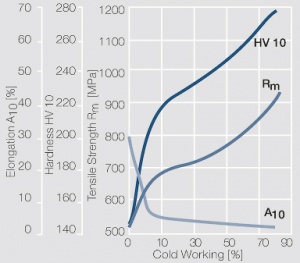

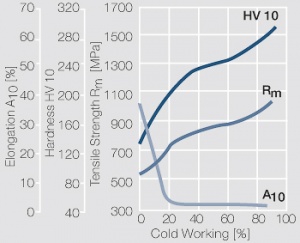

Fig. 2.31: Strain hardening of Pt by cold working | Fig. 2.31: Strain hardening of Pt by cold working | ||

| Line 45: | Line 45: | ||

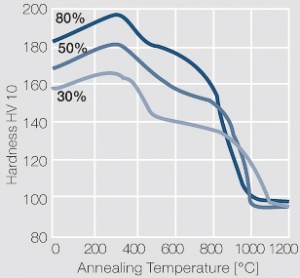

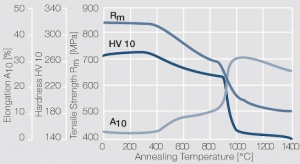

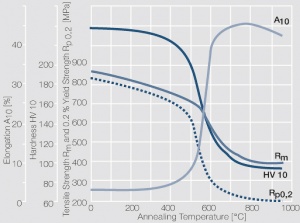

Fig. 2.32: Softening of Pt after annealing for 0.5 hrs after 80% cold working | Fig. 2.32: Softening of Pt after annealing for 0.5 hrs after 80% cold working | ||

| − | <xr id="fig:" | + | <xr id="fig:Strain_hardening_of_PtIr5_by_cold_working"/> |

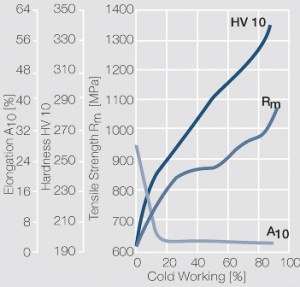

Fig. 2.33: Strain hardening of PtIr5 by cold working | Fig. 2.33: Strain hardening of PtIr5 by cold working | ||

| − | <xr id="fig: | + | <xr id="fig:Softening_of_PtIr5_after_annealing_for_1_hr_after_different_degrees_of_cold_working"/> |

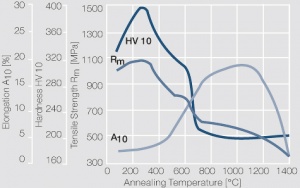

Fig. 2.34: Softening of PtIr5 after annealing for 1 hr after different degrees of cold working | Fig. 2.34: Softening of PtIr5 after annealing for 1 hr after different degrees of cold working | ||

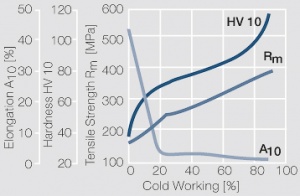

| − | <xr id="fig: | + | <xr id="fig:Strain_hardening_of_PtNi8_by_cold_working"/>Fig. 2.35: Strain hardening of PtNi8 by cold working |

| − | <xr id="fig: | + | <xr id="fig:Softening_of_PtNi8_after_annealing_for_1_hr_after_80%_cold_working"/> |

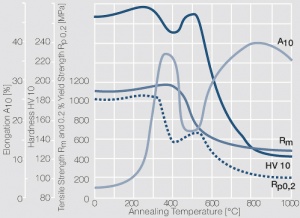

Fig. 2.36: Softening of PtNi8 after annealing for 1 hr after 80% cold working | Fig. 2.36: Softening of PtNi8 after annealing for 1 hr after 80% cold working | ||

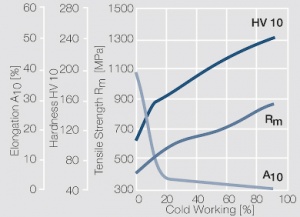

| − | <xr id="fig: | + | <xr id="fig:Strain_hardening_of_PtW5_by_cold_working"/>Fig. 2.37: Strain hardening of PtW5 by cold working |

| − | <xr id="fig: | + | <xr id="fig:Softening_of_PtW5_after_annealing_for_1_hr_after_80%_cold_working"/>Fig. 2.38: Softening of PtW5 after annealing for 1hr after 80% cold working |

| − | <xr id="fig: | + | <xr id="fig:Strain_hardening_of_Pd_99.99_by_cold_working"/>Fig. 2.39: Strain hardening of Pd 99.99 by cold working |

| − | <xr id="fig: | + | <xr id="fig:Strain_hardening_of_PdCu15_by_cold_working"/>Fig. 2.40: Strain hardening of PdCu15 by cold working |

| − | <xr id="fig: | + | <xr id="fig:Softening_of_ PdCu15_after_annealing_for_0.5_hrs"/>Fig. 2.41: Softening of PdCu15 after annealing for 0.5 hrs |

| − | <xr id="fig: | + | <xr id="fig:Strain_hardening_of_PdCu40_by_cold_working"/>Fig. 2.42: Strain hardening of PdCu40 by cold working |

| − | <xr id="fig: | + | <xr id="fig:Softening_of_PdCu40_after_annealing_for_0.5_hrs_after_80%_cold_working"/>Fig. 2.43: Softening of PdCu40 after annealing for 0.5 hrs after 80% cold working |

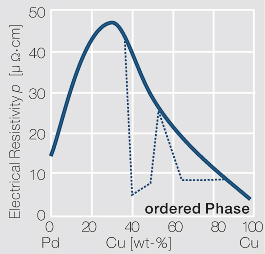

| − | <xr id="fig: | + | <xr id="fig:Electrical_resistivity_p_of_PdCu_alloys"/>Fig. 2.44: Electrical resistivity p of PdCu alloys with and without an annealing step for forming an ordered phase |

<xr id="fig:Contact_and_Switching_Properties_of_the_Platinum_Metals_and_their_Alloys"/>'''Table 2.9: Contact and Switching Properties of the Platinum Metals and their Alloys''' | <xr id="fig:Contact_and_Switching_Properties_of_the_Platinum_Metals_and_their_Alloys"/>'''Table 2.9: Contact and Switching Properties of the Platinum Metals and their Alloys''' | ||

Revision as of 16:48, 13 February 2014

The platinum group metals include the elements Pt, Pd, Rh, Ru, Ir, and Os (Table 2.6). For electrical contacts platinum and palladium have practical significance as base alloy materials and ruthenium and iridium are used as alloying components. Pt and Pd have similar corrosion resistance as gold but because of their catalytical properties they tend to polymerize adsorbed organic vapors on contact surfaces. During frictional movement between contact surfaces the polymerized compounds known as “brown powder” are formed which can lead to significantly increase in contact resistance. Therefore Pt and Pd are typically used as alloys and not in their pure form for electrical contact applications.

Rhodium is not used as a solid contact material but is applied for example as a electroplated layer in sliding contact systems. Ruthenium is mostly used as an alloying component in the material PdRu15. The metals osmium and iridium have no practical applications in electrical contacts.

Since Pd was for the longest time rather stable in price it was looked at as a substitute for the more expensive gold. This was followed by a steep increase in the Pd price which caused a significant reduction in its use in electrical contacts. Today (2011) the Pd price again is lower than that of gold.

Alloys of Pt with Ru, Ir, Ni, and W were widely used in electromechanical components in the telecommunication industry and in heavy duty automotive breaker points (Table 2.7). Today these components have been replaced in many applications by solid state technology and the usage of these materials is greatly reduced. Pd alloys however have a more significant importance. PdCu15 is widely used for example in automotive flasher relays. Because of their resistance to sulfide formation PdAg alloys are applied in various relay designs. The ability to thermally precipitation harden some multi component alloys based on PdAgAuPt they find special usage in wear resistant sliding contact applications. Pd44Ag38Cu15PtAuZn is a standard alloy in this group.

Platinum and palladium alloys are mainly used similar to the gold based materials in the form of welded wire and profile segments but rarely as contact rivets. Because of the high precious metal prices joining technologies are used that allow the most economic application of the contact alloy in the area where functionally needed. Because of their resistance to material transfer they are used for DC applications and due to their higher arc erosion resistance they are applied for medium electrical loads up to about 30W in relays and switches (Table 2.10). Multi-component alloys based on Pd with higher hardness and wear resistance are mainly used as spring arms in sliding contact systems and DC miniature motors.

DEVELOP:ImageLIst

BEGIN=

Table 1 Properties, Production Processes, and Application Forms for Platinum Metals

Table 2

Physical Properties of the Platinum Metals and their Alloys

Table 3 Table 2.8: Mechanical Properties of the Platinum Metals and their Alloys

Figure 1 Fig. 2.25: Influence of 1-20 atom% of different additive metals on the electrical resistivity p of platinum (Degussa)

Figure 2 Fig. 2.26: Influence of 1-22 atom% of different additive metals on the electrical resistivity p of palladium

Figure 3 Fig. 2.27: Phase diagram of platinum-iridium

Figure 4 Fig. 2.28: Phase diagram of platinum-nickel

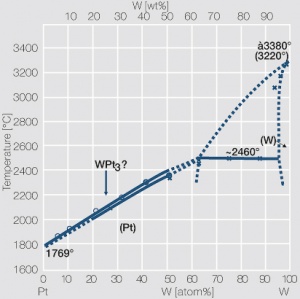

Figure 5 Fig. 2.29: Phase diagram of platinum-tungsten

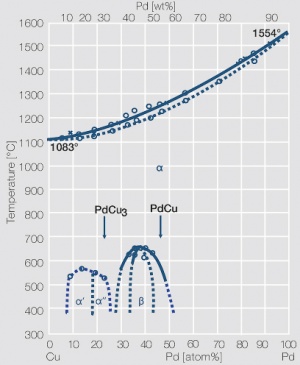

Figure 6 Fig. 2.30: Phase diagram of palladium-copper

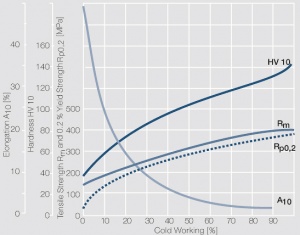

Figure 7 Fig. 2.31: Strain hardening of Pt by cold working

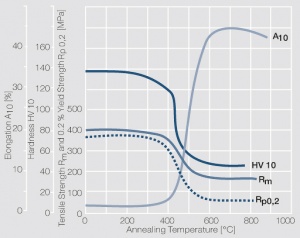

??? Fig. 2.32: Softening of Pt after annealing for 0.5 hrs after 80% cold working

Figure 9 Fig. 2.33: Strain hardening of PtIr5 by cold working

??? Fig. 2.34: Softening of PtIr5 after annealing for 1 hr after different degrees of cold working

Figure 11Fig. 2.35: Strain hardening of PtNi8 by cold working

Figure 12 Fig. 2.36: Softening of PtNi8 after annealing for 1 hr after 80% cold working

Figure 13Fig. 2.37: Strain hardening of PtW5 by cold working

Figure 14Fig. 2.38: Softening of PtW5 after annealing for 1hr after 80% cold working

Figure 15Fig. 2.39: Strain hardening of Pd 99.99 by cold working

Figure 16Fig. 2.40: Strain hardening of PdCu15 by cold working

???Fig. 2.41: Softening of PdCu15 after annealing for 0.5 hrs

Figure 18Fig. 2.42: Strain hardening of PdCu40 by cold working

Figure 19Fig. 2.43: Softening of PdCu40 after annealing for 0.5 hrs after 80% cold working

Figure 20Fig. 2.44: Electrical resistivity p of PdCu alloys with and without an annealing step for forming an ordered phase

Table 4Table 2.9: Contact and Switching Properties of the Platinum Metals and their Alloys

Table 5Table 2.10: Application Examples and Form of Supply for Platinum Metals and their Alloys

END=

Table 2.6: Properties, Production Processes, and Application Forms for Platinum Metals

Table 2.8: Mechanical Properties of the Platinum Metals and their Alloys

soft | 70% cold worket | soft | 70% cold worket | soft | 70% cold worket | |

Pt (99,95) | 150 | 360 | 40 | 3 | 40 | 120 |

PtIr5 | 260 | 550 | 25 | 2 | 85 | 160 |

PtIr10 | 340 | 570 | 24 | 2 | 105 | 210 |

PtRu10 | 650 | 1000 | 24 | 2 | 195 | 320 |

PtNi8 | 640 | 950 | 22 | 2 | 200 | 320 |

PtW5 | 530 | 860 | 21 | 2 | 150 | 270 |

Pd (99,95) | 200 | 420 | 42 | 2 | 40 | 90 |

PdCu15 | 400 | 780 | 38 | 2 | 90 | 220 |

PdCu40 | 550 | 950 | 35 | 2 | 120 | 260 |

PdNi5 Pd35AuAgPt | 340 | 700 | 25 | 2 | 95 | 200 420* |

Pd44Ag38Cu15 | 405* | |||||

PtAuZn Pd40Co40W20 | 680* | |||||

*maximum hardness |

Fig. 2.27: Phase diagram of platinum-iridium

Fig. 2.28: Phase diagram of platinum-nickel

Fig. 2.29: Phase diagram of platinum-tungsten

Fig. 2.30: Phase diagram of palladium-copper

Fig. 2.31: Strain hardening of Pt by cold working

Fig. 2.32: Softening of Pt after annealing for 0.5 hrs after 80% cold working

Fig. 2.33: Strain hardening of PtIr5 by cold working

Fig. 2.34: Softening of PtIr5 after annealing for 1 hr after different degrees of cold working

Fig. 2.35: Strain hardening of PtNi8 by cold working

Fig. 2.36: Softening of PtNi8 after annealing for 1 hr after 80% cold working

Fig. 2.37: Strain hardening of PtW5 by cold working

Fig. 2.38: Softening of PtW5 after annealing for 1 hr after 80% cold working

Fig. 2.40: Strain hardening of PdCu15 by cold working

Fig. 2.41: Softening of PdCu15 after annealing for 0.5 hrs

Fig. 2.42: Strain hardening of PdCu40 by cold working

Fig. 2.43: Softening of PdCu40 after annealing for 0.5 hrs after 80% cold working

Fig. 2.44: Electrical resistivity p of PdCu alloys with and without an annealing step for forming an ordered phase

Table 2.9: Contact and Switching Properties of the Platinum Metals and their Alloys

Material | Properties | |

Pt | Very high corrosion resistance | |

PtIr5 - 10 | Very high corrosion resistance, low contact resistance | High arc erosion resistance, high hardness |

PtRu10 | Very high corrosion resistance, low welding tendency | Low contact resistance, very high hardness |

PtNi8 | Low material transfer tendency | Very high hardness |

PtW5 | Low material transfer tendency | High hardness |

Pd | Strong tendency to “Brown Powder” formation | Less arc erosion resistant than Pt |

PdCu15 PdCu40 | Tendency to “Brown Powder” formation | Mostly resistant to material transfer, high hardness |

PdNi5 | Strong tendency to “Brown Powder” formation | Low welding tendency |

Pd44Ag38Cu15 PtAuZn | High mechanical wear resistance | Standard material for sliding contact brushes |

Table 2.10: Application Examples and Form of Supply for Platinum Metals and their Alloys

Material | Application Examples | Forms of Supply |

Pt (99,95) | Relays | Contact rivets, welded contact parts |

PtIr5 PtIr10 PtRu10 PtNi8 PtW5 | Relays, sliding contact systems, automotive ignition breaker points | Semi-finished Contact Materials: Wire, seam-welded contact profiles Contact Parts: Tips, wire-formed parts, solid and composite contact rivets, welded contact parts |

Pd (99,95) PdNi5 | Relays | Micro-profiles (weld tapes), contact rivets, welded contact parts |

PdCu15 PdCu40 | Automotive flasher relays | Micro-profiles, composite contact rivets |

Pd35AuAgPt Pd44Ag38Cu15 PtAuZn Pd40Co40W20 | Potentiometers, slip rings, miniature DC motors | Wire-formed parts, welded wire segments, multi-arm sliding contact brushes |