Semi-finished contact pre-materials can be manufactured from solid precious metals, precious metal alloys or precious metal containing composite materials. They are made in wire, strip and profile form by known processing technologies such as extrusion and subsequent annealing and drawing or roll-forming. They are supplied following the manufacturer's internal standards usually related to DIN EN specifications for copper based materials. The most important materials are two – or multiple material layered semi-finished materials with t...

Difference between revisions of "Data Book of Electrical Contacts"

From Electrical Contacts

Teitscheid (talk | contribs) |

|||

| (30 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

| − | {| | + | |

| − | | | + | {|class="mainPage" cellpadding="0" cellspacing="10" |

| − | + | |{{MainArticles}} | |

| − | |||

|<h4>Featured Files</h4> | |<h4>Featured Files</h4> | ||

| + | {{MainPicture}} | ||

| + | |} | ||

| − | + | [[de:Wiki_der_elektrischen_Kontakte]] | |

| − | |||

| − | |||

| − | [[ | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

__NOTOC__ | __NOTOC__ | ||

__NOEDITSECTION__ | __NOEDITSECTION__ | ||

Latest revision as of 15:18, 26 September 2014

Welcome to our Wiki of electrical contactsThe basis of this Wiki is the 2012 issue of the "DODUCO Data Book of Electrical Contacts" which is also available in printed form. For further questions or help, please contact us directly under Contact DODUCO

Featured Article |

Featured Files

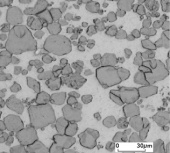

Micro structure of W/Cu 70/30 G

Pages: Tungsten and Molybdenum Based Materials, Werkstoffe auf Wolfram- und Molybdän-Basis by Doduco Redaktion

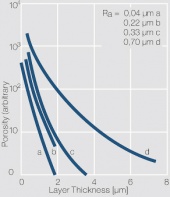

Porosity of an electroplated hard gold layer as a function of the layer thickness at different surface roughness values Ra

Pages: Testing of Contact Surface Layers, Prüfung von Kontaktschichten by Doduco Redaktion |