Difference between revisions of "Physical Effects in Sliding and Connector Contacts"

From Electrical Contacts

(→6.4.5 Physical Effects in Sliding and Connector Contacts) |

Doduco Admin (talk | contribs) (→Physical Effects in Sliding and Connector Contacts) |

||

| (18 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | ===6.4.5 Physical Effects in Sliding and Connector Contacts=== | + | ===<!--6.4.5-->Physical Effects in Sliding and Connector Contacts=== |

| + | |||

| + | '''Mechanical wear of sliding contacts''' | ||

| + | |||

| + | <table class="twocolortable" style="text-align: left; font-size:12px;width:40%"> | ||

| + | <tr> | ||

| + | <td>dV/dx = k x F<sub>K</sub> /3 H<sub>W</sub></td> | ||

| + | </tr><tr> | ||

| + | <td>dV/dx Wear volume in mm<sup>3</sup> per slide path length in mm</td> | ||

| + | </tr><tr> | ||

| + | <td>k Coefficient of frictional wear</td> | ||

| + | </tr><tr> | ||

| + | <td>H<sub>W</sub> Hardness of the softer material <br />(Brinell or Vickers units)</td> | ||

| + | </tr><tr> | ||

| + | <td>F<sub>K</sub> Contact force in cN</td> | ||

| + | </tr><tr> | ||

| + | <td>'''Wear coefficient k during material transfer'''</td> | ||

| + | </tr><tr> | ||

| + | <td>Silver – Silver 120 x 10<sup>-4</sup></td> | ||

| + | </tr><tr> | ||

| + | <td>Platinum – Platinum 400 x 10<sup>-4</sup></td> | ||

| + | </tr><tr> | ||

| + | <td>Silver – Platinum 1.3 x 10<sup>-4</sup></td> | ||

| + | </tr><tr> | ||

| + | <td>'''Coefficient of fractional wear k during wear loss'''</td> | ||

| + | </tr><tr> | ||

| + | <td>Silver – silver 8 x 10<sup>-4</sup></td> | ||

| + | </tr><tr> | ||

| + | <td>Gold – gold 9 x 10<sup>-4</sup></td> | ||

| + | </tr><tr> | ||

| + | <td>Platinum – platinum 40 x 10<sup>-4</sup></td> | ||

| + | </tr><tr> | ||

| + | <td>Silver – gold 9 x 10<sup>-4</sup></td> | ||

| + | </tr><tr> | ||

| + | <td>Silver – platinum 5 x 10<sup>-4</sup></td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | '''Contact behavior of connectors''' | ||

| + | <div class="multiple-images"> | ||

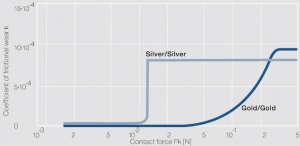

| + | [[File:Coefficient of frictional wear for the wear loss of sliding contacts Silver Silver.jpg|left|thumb|Figure 1: Coefficient of frictional wear for the wear loss of sliding contacts Silver/Silver and hard gold/hard gold as a function of the contact force]] | ||

| − | [[File: | + | <figure id="fig:Contact resistance Rk as a function of the contact force Fk"> |

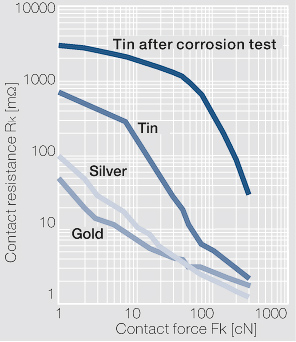

| + | [[File:Contact resistance Rk as a function of the contact force Fk.jpg|left|thumb|Figure 2: Contact resistance R<sub>k</sub> as a function of the contact force F<sub>k</sub> for different surface coating materials. Measured against a spherical gold probe; I = 10 mA, U < 20 mV]] | ||

| + | </figure> | ||

| − | + | <figure id="fig:Contact resistance Rk as a function of the fretting wear cycles"> | |

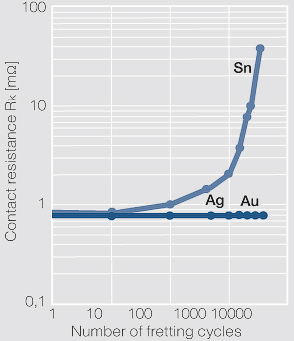

| − | + | [[File:Contact resistance Rk as a function of the fretting wear cycles.jpg|left|thumb|Figure 3: Contact resistance R<sub>k</sub> as a function of the fretting wear cycles for different surface coating materials]] | |

| + | </figure> | ||

| + | </div> | ||

| + | <div class="clear"></div> | ||

| − | |||

| − | + | <figtable id="tab:Surface Coating Materials for Connectors"> | |

| − | + | <caption>'''<!--Tab.6.4:-->Surface Coating Materials for Connectors'''</caption> | |

| − | |||

| − | |||

| − | |||

| − | + | {| class="twocolortable" style="text-align: left; font-size: 12px" | |

| − | + | |- | |

| − | + | !Manufacturing method | |

| − | + | !Coating materials | |

| + | !Intermediate layer | ||

| + | !Hardness HV | ||

| + | !Frictional factor | ||

| + | |- | ||

| + | |Electroplating | ||

| + | |Tin<br />Nickel<br />Nickel-phosphorus (NiP 6 - 15)<br />Silver<br />Hard gold (< 0.3 wt% Ni or Co)<br />Palladium with Au- flash (<0,2μm)<br />Palladium-nickel with Au-flash (<0.2μm) | ||

| + | |For brass: Copper or Nickel<br /> <br /> <br /> <br />Nickel, Nickel-phosphorus<br />Nickel<br />Nickel | ||

| + | |50 - 90<br />300 - 600<br />500 - 1100<br />70 - 100<br />100 - 200<br />250 - 300<br />300 - 400 | ||

| + | |0.5 - 1<br /> <br /> <br />0.5 - 0.8<br />0.2 - 0.5<br />0.2 - 0.5<br />0.2 - 0.5 | ||

| + | |- | ||

| + | |Cladding | ||

| + | |Gold-nickel (AuNi 5 -10)<br />Silber-palladium (AgPd 10 - 30) | ||

| + | |Nickel<br />Nickel | ||

| + | |160 - 200<br />120 - 170 | ||

| + | |0.2 - 0.5<br />0.2 - 0.5 | ||

| + | |- | ||

| + | |Hot-dipped tinning | ||

| + | |Tin | ||

| + | |Inter-metallic compound[[#text-reference|<sup>(1)</sup>]] Tin–copper | ||

| + | |400 - 500 | ||

| + | | | ||

| + | |} | ||

| + | <div id="text-reference">(1) is formed during hot tinning process</div> | ||

| + | </figtable> | ||

| − | + | <div class="clear"></div> | |

==References== | ==References== | ||

[[Application Tables and Guideline Data for Use of Electrical Contact Design#References|References]] | [[Application Tables and Guideline Data for Use of Electrical Contact Design#References|References]] | ||

| + | |||

| + | [[de:Physikalische_Effekte_bei_Gleit-_und_Steckkontakten]] | ||

Latest revision as of 12:45, 11 January 2023

Physical Effects in Sliding and Connector Contacts

Mechanical wear of sliding contacts

| dV/dx = k x FK /3 HW |

| dV/dx Wear volume in mm3 per slide path length in mm |

| k Coefficient of frictional wear |

| HW Hardness of the softer material (Brinell or Vickers units) |

| FK Contact force in cN |

| Wear coefficient k during material transfer |

| Silver – Silver 120 x 10-4 |

| Platinum – Platinum 400 x 10-4 |

| Silver – Platinum 1.3 x 10-4 |

| Coefficient of fractional wear k during wear loss |

| Silver – silver 8 x 10-4 |

| Gold – gold 9 x 10-4 |

| Platinum – platinum 40 x 10-4 |

| Silver – gold 9 x 10-4 |

| Silver – platinum 5 x 10-4 |

Contact behavior of connectors

Table 1: Surface Coating Materials for Connectors

| Manufacturing method | Coating materials | Intermediate layer | Hardness HV | Frictional factor |

|---|---|---|---|---|

| Electroplating | Tin Nickel Nickel-phosphorus (NiP 6 - 15) Silver Hard gold (< 0.3 wt% Ni or Co) Palladium with Au- flash (<0,2μm) Palladium-nickel with Au-flash (<0.2μm) |

For brass: Copper or Nickel Nickel, Nickel-phosphorus Nickel Nickel |

50 - 90 300 - 600 500 - 1100 70 - 100 100 - 200 250 - 300 300 - 400 |

0.5 - 1 0.5 - 0.8 0.2 - 0.5 0.2 - 0.5 0.2 - 0.5 |

| Cladding | Gold-nickel (AuNi 5 -10) Silber-palladium (AgPd 10 - 30) |

Nickel Nickel |

160 - 200 120 - 170 |

0.2 - 0.5 0.2 - 0.5 |

| Hot-dipped tinning | Tin | Inter-metallic compound(1) Tin–copper | 400 - 500 |

(1) is formed during hot tinning process