Difference between revisions of "Stamped Contact Parts"

(→Stamped Contact Parts) |

Doduco Admin (talk | contribs) (→Types of Stamped Parts) |

||

| (49 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

| − | Stamped electrical contact parts typically consist of a base carrier material to | + | ==Stamped Contact Parts== |

| − | which a contact material is attached by various methods | + | Stamped electrical contact parts typically consist of a base carrier material to which a contact material is attached by various methods. |

| − | as the important functional components in many switching and | + | <figure id="fig:Plated_and_contact_containing_pre_stamped_strips_and_stamped_parts"> |

| − | electromechanical devices for a broad range of electrical and electronic | + | [[File:Plated and contact containing pre-stamped strips and stamped parts.jpg|right|thumb|Figure 1: Plated and contact containing pre-stamped strips and stamped parts for different applications]] |

| − | applications. | + | </figure> |

| − | current transfer and the closing and opening of electrical circuits. In addition the | + | They serve as the important functional components in many switching and electromechanical devices for a broad range of electrical and electronic |

| − | contact carriers are important mechanical design components selected to meet | + | applications. A great advantage ist that they perform the mostly loss-free electrical current transfer and the closing and opening of electrical circuits. In addition, the contact carriers are important mechanical design components, selected to meet the requirements on electrical, thermal, mechanical, and magnetic properties. |

| − | the requirements on electrical, thermal, mechanical and magnetic properties. | ||

| − | The increasing miniaturization of electromechanical components requires ever | + | The increasing miniaturization of electromechanical components requires ever smaller stamped parts with low dimensional tolerances. Such precision |

| − | smaller stamped parts with low dimensional tolerances. Such precision | + | stamped parts are needed in the automotive technology for highly reliable switching and connector performance. In the information and data processing |

| − | stamped parts are needed in the automotive technology for highly reliable | + | technology they transfer signals and control impulses with high reliability and serve as the interface between electronic and electrical components. |

| − | switching and connector performance. In the information and data processing | ||

| − | technology they transfer signals and control impulses with high reliability and | ||

| − | serve as the interface between electronic and electrical components. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | === Types of Stamped Parts=== | ||

| + | Stamped parts are produced as single pieces, in pre-stamped strip and comb configurations. Depending on the requirements and application the contact and base material as well as the coating and attachment technology is carefully selected. | ||

| − | + | *'''Coated stamped parts''' | |

| − | Stamped parts | + | Stamped parts can be selectively or completely coated with precious metal, containing materials based on gold, palladium, and silver as well as |

| − | + | non-precious materials such as tin, nickel and copper. | |

| − | + | For stamped parts in high volumes like those used as electrical components in automobiles, the carrier material is mostly coated in a reel-to-reel process, starting with either solid or pre-stamped strips (see also chapter [[Electroplating (or Galvanic Deposition)#Electroplating of Semi-finished Materials| Electroplating of Semi-finished Materials]]). Frequently the prestamped strip will be used directly in further automated assembly of the finished functional component (<xr id="fig:Plated_and_contact_containing_pre_stamped_strips_and_stamped_parts"/>). As an alternative, finished stamped parts can be electroplated using barrel and rack plating methods. | |

| − | |||

| − | + | Very thin coating layers with tight tolerances are deposited by electroplating. For many applications, the high mechanical wear resistance is advantageous. Since even, very thin layers are mostly pore-free. These coatings also act as an effective corrosion inhibitor. The type of coatings, the sequence of multiple layers and the coating thickness, for example for connectors, are chosen according to the requirements for the end application. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *'''Clad stamped parts''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | For many applications, thicker precious metal surfaces or AlSi layers are necessary. These cannot be deposited by electroplating. Besides meltmetallurgically produced materials on the basis of gold, palladium and silver, also powder-metallurgical materials are required frequently. The metallurgical bond between these contact materials and the mostly copper based substrates is achieved through various mechanical cladding methods (see also chapter [[Manufacturing of Semi-Finished Materials#Clad Semi-Finished Pre-Materials (Contact-Bimetals)| Clad Semi-Finished Pre-Materials (Contact-Bimetals)]]). In this way, also aluminum clad strips are manufactured in which the aluminum layer serves as the bondable surface in the interface between electromechanical connections and electronic circuits. These clad semifinished materials can be further fabricated into pre-stamped strips, in comb form or single stamped parts (<xr id="fig:Examples of clad stamped parts"/><!--(Fig. 3.18)-->). | |

| − | + | <figure id="fig:Examples of clad stamped parts"> | |

| − | + | [[File:Examples of clad stamped parts.jpg|right|thumb|Figure 2: Examples of clad stamped parts]] | |

| − | + | </figure> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *'''Welded stamped parts''' | |

| − | |||

| − | + | Welded stamped parts can be fabricated by various methods (see also chapter [[Attachment of Single Contact Parts#Welding Processes| Welding Processes]]). Single contact pieces can be attached to pre-stamped or finished stamped strips as weld buttons and wire or profile segments by electrical resistance welding. Contact parts can also be stamped from seam-welded, semi-finished strip. Fitting the end application contact materials based on gold, palladium and silver. Depending on the contact material and the design of the finished contact component, the contact bottom surface may be consist of a weldable backing material. | |

| − | + | *'''Brazed stamped parts''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Brazed stamped contact assemblies are manufactured by two joining methods (see also chapter [[Attachment of Single Contact Parts#Brazing Processes| Brazing Processes]]). The contact material is either attached by resistance or induction brazing to base metal carriers as prefabricated contact tip or they are stamped from brazed semi-finished toplay strip. It is typical for brazed contact parts that the contact material consists of silver based contact material and a good conducting copper base material with larger cross-sectional area for the usually higher current carrying capacity. | |

| − | + | *'''Stamped contact parts with rivets''' | |

| − | |||

| − | |||

| − | |||

| − | contact parts | ||

| − | |||

| − | |||

| − | + | Riveted stamped contact parts are manufactured with the use of contact rivets, which are transferred over suitable feed mechanisms correctly oriented into holes punched into the carrier (<xr id="fig:Examples of riveted stamped parts"/><!--(Fig. 3.19)-->). Frequently; also wire or wire segments resp. are used which are subsequently coined and formed into the desired contact shape (see also chapter [[Attachment of Single Contact Parts#Mechanical Attachment Processes| Mechanical Attachment Processes]]). Both attachment methods have their distinct advantages. Using composite or tri-metal rivets allows limiting the use of precious metal custom tailored to the volume needed for specific switching requirements. For wire staking, the precious metal usage is usually higher but the staking can be performed at significantly higher production rates and the additional rivet making step is eliminated. | |

| + | <figure id="fig:Examples of riveted stamped parts"> | ||

| + | [[File:Examples of riveted stamped parts.jpg|right|thumb|Figure 3: Examples of riveted stamped parts]] | ||

| + | </figure> | ||

| − | + | *'''Pre-mounted component stamped parts''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | Fig. 3. | + | Components stamped parts consist of a minimum of two carrier parts which differ in their material composition and geometrical form and the contact |

| − | Examples of | + | material (<xr id="fig:Examples of pre-mounted stamped component parts"/><!--(Fig. 3.20?)-->). The assembly of these components as single pieces or stamping progressions is performed in a stamping die by riveting or coining. To increase the current carrying capacity at the joining area, an additional welding step can be added. Depending on the requirements, the different properties of the two carrier components can be combined. As an example: the high electrical conductivity of a contact carrier blade is joined with the thermal or mechanical spring properties of a second material to form a functional component. For this process, both carrier base materials can also be coated with additional layers of other functional materials. |

| + | <figure id="fig:Examples of pre-mounted stamped component parts"> | ||

| + | [[File:Examples of pre-mounted stamped component parts.jpg|right|thumb|Figure 4: Examples of pre-mounted stamped component parts]] | ||

| + | </figure> | ||

| − | + | Stamped parts which are insert molded into or combined with plastic parts are used in electromechanical components (see Chapter [[Electromechanical Components | Electromechanical Components ]]). | |

| − | + | === Stamping Tools=== | |

| − | + | For the design of stamping tools the latest CAD software systems are used. | |

| − | + | Modern stamping tools usually employ a modular design with integrated dimensional and functional controls (<xr id="fig:Progressive die for stamped contact parts"/><!--(Fig. 3.21)-->). | |

| − | + | <figure id="fig:Progressive die for stamped contact parts"> | |

| − | + | [[File:Progressive die for stamped contact parts.jpg|right|thumb|Figure 5: Progressive die for stamped contact parts]] | |

| − | + | </figure> | |

| − | + | Depending on part and volume requirements, they are built with steel or carbide inserts that are also coated with a wear-resistant material such as TiN for longer life. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | A special stamping process is precision stamping for contact parts, made from thin strip materials with thicknesses in the range of 0.05 – 2.5 mm. With the high capacity stamping technology, up to 1400 strokes/min can be reached for high volume parts. During the actual stamping operation, frequently other processes such as thread-forming, welding of contact segments and insertion and forming of contacts from wire segments are integrated. Depending on the production volume, these operations can also be performed several times. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The quality of the tools used for stamping, like progressive dies and stamp-forming tools is important for the final precision and consistency of the parts. During high speed stamping the tools are exposed to extreme mechanical stresses which must be compensated, to ensure the highest precision over long production runs. With such high quality, progressive dies parts of high precision with a cutting width of less than the material thickness and with strict quality requirements for the cutting surfaces, can be manufactured. | |

| − | + | To ensure the highest demands on the surface quality of precision contact parts, quite often vanishing oils are used as tool lubricants. Cleaning and degreasing operations can also be integrated into the stamping process. Additionally, most stamping lines are also equipped with test stations for a 100% dimensional and surface quality control. | |

| − | + | During the design of stamping tools for electrical contacts, minimizing of process scrap and the possibility to separate the precious metal containing scrap must be considered. | |

| − | |||

| − | |||

| − | of contacts | ||

| − | |||

| − | + | ==References== | |

| − | + | [[:Manufacturing Technologies for Contact Parts#References|References]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[de:Stanzteile]] | |

| − | |||

| − | [[ | ||

Latest revision as of 08:18, 9 January 2023

Stamped Contact Parts

Stamped electrical contact parts typically consist of a base carrier material to which a contact material is attached by various methods.

They serve as the important functional components in many switching and electromechanical devices for a broad range of electrical and electronic applications. A great advantage ist that they perform the mostly loss-free electrical current transfer and the closing and opening of electrical circuits. In addition, the contact carriers are important mechanical design components, selected to meet the requirements on electrical, thermal, mechanical, and magnetic properties.

The increasing miniaturization of electromechanical components requires ever smaller stamped parts with low dimensional tolerances. Such precision stamped parts are needed in the automotive technology for highly reliable switching and connector performance. In the information and data processing technology they transfer signals and control impulses with high reliability and serve as the interface between electronic and electrical components.

Types of Stamped Parts

Stamped parts are produced as single pieces, in pre-stamped strip and comb configurations. Depending on the requirements and application the contact and base material as well as the coating and attachment technology is carefully selected.

- Coated stamped parts

Stamped parts can be selectively or completely coated with precious metal, containing materials based on gold, palladium, and silver as well as non-precious materials such as tin, nickel and copper. For stamped parts in high volumes like those used as electrical components in automobiles, the carrier material is mostly coated in a reel-to-reel process, starting with either solid or pre-stamped strips (see also chapter Electroplating of Semi-finished Materials). Frequently the prestamped strip will be used directly in further automated assembly of the finished functional component (Figure 1). As an alternative, finished stamped parts can be electroplated using barrel and rack plating methods.

Very thin coating layers with tight tolerances are deposited by electroplating. For many applications, the high mechanical wear resistance is advantageous. Since even, very thin layers are mostly pore-free. These coatings also act as an effective corrosion inhibitor. The type of coatings, the sequence of multiple layers and the coating thickness, for example for connectors, are chosen according to the requirements for the end application.

- Clad stamped parts

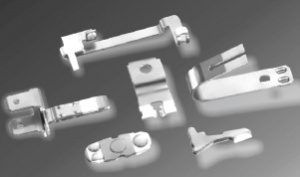

For many applications, thicker precious metal surfaces or AlSi layers are necessary. These cannot be deposited by electroplating. Besides meltmetallurgically produced materials on the basis of gold, palladium and silver, also powder-metallurgical materials are required frequently. The metallurgical bond between these contact materials and the mostly copper based substrates is achieved through various mechanical cladding methods (see also chapter Clad Semi-Finished Pre-Materials (Contact-Bimetals)). In this way, also aluminum clad strips are manufactured in which the aluminum layer serves as the bondable surface in the interface between electromechanical connections and electronic circuits. These clad semifinished materials can be further fabricated into pre-stamped strips, in comb form or single stamped parts (Figure 2).

- Welded stamped parts

Welded stamped parts can be fabricated by various methods (see also chapter Welding Processes). Single contact pieces can be attached to pre-stamped or finished stamped strips as weld buttons and wire or profile segments by electrical resistance welding. Contact parts can also be stamped from seam-welded, semi-finished strip. Fitting the end application contact materials based on gold, palladium and silver. Depending on the contact material and the design of the finished contact component, the contact bottom surface may be consist of a weldable backing material.

- Brazed stamped parts

Brazed stamped contact assemblies are manufactured by two joining methods (see also chapter Brazing Processes). The contact material is either attached by resistance or induction brazing to base metal carriers as prefabricated contact tip or they are stamped from brazed semi-finished toplay strip. It is typical for brazed contact parts that the contact material consists of silver based contact material and a good conducting copper base material with larger cross-sectional area for the usually higher current carrying capacity.

- Stamped contact parts with rivets

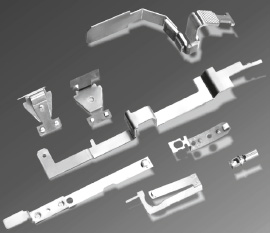

Riveted stamped contact parts are manufactured with the use of contact rivets, which are transferred over suitable feed mechanisms correctly oriented into holes punched into the carrier (Figure 3). Frequently; also wire or wire segments resp. are used which are subsequently coined and formed into the desired contact shape (see also chapter Mechanical Attachment Processes). Both attachment methods have their distinct advantages. Using composite or tri-metal rivets allows limiting the use of precious metal custom tailored to the volume needed for specific switching requirements. For wire staking, the precious metal usage is usually higher but the staking can be performed at significantly higher production rates and the additional rivet making step is eliminated.

- Pre-mounted component stamped parts

Components stamped parts consist of a minimum of two carrier parts which differ in their material composition and geometrical form and the contact material (Figure 4). The assembly of these components as single pieces or stamping progressions is performed in a stamping die by riveting or coining. To increase the current carrying capacity at the joining area, an additional welding step can be added. Depending on the requirements, the different properties of the two carrier components can be combined. As an example: the high electrical conductivity of a contact carrier blade is joined with the thermal or mechanical spring properties of a second material to form a functional component. For this process, both carrier base materials can also be coated with additional layers of other functional materials.

Stamped parts which are insert molded into or combined with plastic parts are used in electromechanical components (see Chapter Electromechanical Components ).

Stamping Tools

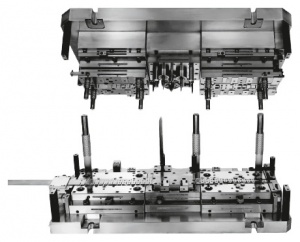

For the design of stamping tools the latest CAD software systems are used. Modern stamping tools usually employ a modular design with integrated dimensional and functional controls (Figure 5).

Depending on part and volume requirements, they are built with steel or carbide inserts that are also coated with a wear-resistant material such as TiN for longer life.

A special stamping process is precision stamping for contact parts, made from thin strip materials with thicknesses in the range of 0.05 – 2.5 mm. With the high capacity stamping technology, up to 1400 strokes/min can be reached for high volume parts. During the actual stamping operation, frequently other processes such as thread-forming, welding of contact segments and insertion and forming of contacts from wire segments are integrated. Depending on the production volume, these operations can also be performed several times.

The quality of the tools used for stamping, like progressive dies and stamp-forming tools is important for the final precision and consistency of the parts. During high speed stamping the tools are exposed to extreme mechanical stresses which must be compensated, to ensure the highest precision over long production runs. With such high quality, progressive dies parts of high precision with a cutting width of less than the material thickness and with strict quality requirements for the cutting surfaces, can be manufactured. To ensure the highest demands on the surface quality of precision contact parts, quite often vanishing oils are used as tool lubricants. Cleaning and degreasing operations can also be integrated into the stamping process. Additionally, most stamping lines are also equipped with test stations for a 100% dimensional and surface quality control. During the design of stamping tools for electrical contacts, minimizing of process scrap and the possibility to separate the precious metal containing scrap must be considered.