Difference between revisions of "Definition of Terms and Symbols"

From Electrical Contacts

Doduco Admin (talk | contribs) (→Definition of Terms and Symbols) |

Doduco Admin (talk | contribs) (→Definition of Terms and Symbols) |

||

| Line 53: | Line 53: | ||

|The incremental electrical resistance generated by the constriction of the currents paths in the touching area (a-spot) | |The incremental electrical resistance generated by the constriction of the currents paths in the touching area (a-spot) | ||

|- | |- | ||

| − | | | + | |Film resistance |

|R<sub>f</sub> | |R<sub>f</sub> | ||

|[Ω] | |[Ω] | ||

| − | | | + | |Generated by a foreign matter layer, which for ex. is formed by a reaction of the contact material surface with the surrounding atmosphere (a surface film is a substance on the contact surface with different properties than those of the actual contact material) |

|- | |- | ||

| − | | | + | |Path resistance |

|R<sub>d</sub> | |R<sub>d</sub> | ||

|[Ω] | |[Ω] | ||

| − | | | + | |the total electrical resistance between reference points (usually the device terminals) which can be freely chosen but must be defined. It is the sum of the conductor resistance R<sub>b</sub> |

| + | and the contact resistance R<sub>k</sub> | ||

|- | |- | ||

| − | | | + | |Contact Force |

|F<sub>k</sub> | |F<sub>k</sub> | ||

|[N] | |[N] | ||

| − | | | + | |The force that is exerted between the two contact parts in the closed position |

|- | |- | ||

|Contour area | |Contour area | ||

Revision as of 13:36, 13 December 2022

Definition of Terms and Symbols

Note: The symbols for electrical contact specific terms i.e. contact area, contact resistance, etc. have been retained from the german version of the Data Book. In related English literature some of them may vary using subscript symbols related to the language used – for example “contact resistance”: as used here from german Rk, in english mostly Rc.

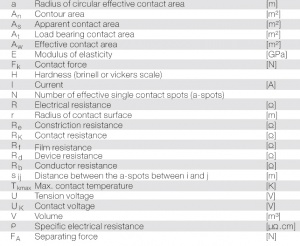

Table 1: Overview of terms and formula symbols

| Term | Formula symbol | Unit | Explanation |

|---|---|---|---|

| Electrical contact | A property which is generated through the touching of two electrically conducting surfaces | ||

| Contact part | A metallic component which is designed to create or interrupt an electrical contact (is frequently replaced by the term “contact” if it is clearly understandable that a physical piece or item is meant) | ||

| Contact area | The whole area on a contact part that may be used for contacting | ||

| Apparent contact area | As | [m2] | The part of the contact area on contact parts that can make physical contact during the touching of two contacts |

| Load bearing contact area | At | [m2] | The part of the apparent contact area which is affected by the contact force. It is the sum of all microscopic actual touching points |

| Effective contact area | Aw | [m2] | The part of the load bearing contact area through which current is flowing and therefore the sum of all current carrying touching areas (a-spots), Aw < At < As |

| Contact resistance | Rk | [Ω] | Composed of the constriction resistance and the film resistance |

| Constriction resistance | Re | [Ω] | The incremental electrical resistance generated by the constriction of the currents paths in the touching area (a-spot) |

| Film resistance | Rf | [Ω] | Generated by a foreign matter layer, which for ex. is formed by a reaction of the contact material surface with the surrounding atmosphere (a surface film is a substance on the contact surface with different properties than those of the actual contact material) |

| Path resistance | Rd | [Ω] | the total electrical resistance between reference points (usually the device terminals) which can be freely chosen but must be defined. It is the sum of the conductor resistance Rb

and the contact resistance Rk |

| Contact Force | Fk | [N] | The force that is exerted between the two contact parts in the closed position |

| Contour area | An | [m2] | The contiguous area which includes all effective a-spots, Aw < An < As ; An ≠ At |

| Radius | a | [m] | Radius der kreisförmigen wirksamen Kontaktfläche |

| Elastizitätsmodul | E | [MPa] | Materialkennwert aus der Werkstofftechnik, der bei linear-elastischem Verhalten den proportionalen Zusammenhang zwischen Spannung und Dehnung bei der Verformung eines festen Körpers beschreibt |

| Härte (Brinell oder Vickers) | H | Der mechanische Widerstand, den ein Werkstoff der mechanischen Eindringung eines anderen Körpers entgegensetzt | |

| Stromstärke | I | [A] | Die elektrische Stromstärke gibt an, wie viel elektrische Ladung sich pro Sekunde durch einen Leiter bewegt |

| Anzahl der wirksamen Einzelkontaktflächen | N | ||

| Elektrischer Widerstand | R | [Ω] | Der elektrische Widerstand ist in der Elektrotechnik ein Maß dafür, welche elektrische Spannung erforderlich ist, um eine bestimmte elektrische Stromstärke durch einen elektrischen Leiter (Bauelement, Stromkreis) fließen zu lassen |

| Radius Kontaktfläche | r | [m] | |

| Bahnwiderstand | Rb | [Ω] | Der elektrische Widerstand eines Halbleiterkristalls im p- bzw. n-dotierten Gebiet im Gegensatz zum Widerstand RÜ im Bereich der Übergangszone |

| Abstand der wirksamen Einzelkontaktflächen zwischen i und j | sij | [m] | |

| Maximale Kontakttemperatur | TKmax | [K] | |

| Spannung | U | [V] | Je größer die elektrische Spannung ist, desto mehr Ladung kann transportiert werden und dadurch steigt auch die elektrische Stromstärke, also die Ladungsmenge |

| Kontaktspannung | UK | [V] | Die bei Berührung zweier unterschiedlicher Substanzen entstehende elektrische Spannung. Die Ursache hierfür sind letztlich die unterschiedlichen Elektronenniveaus in den Materialien |

| Volumen | V | [m3] | Das Volumen ist der räumliche Inhalt eines geometrischen Körpers |

| Spezifischer Widerstand | ρ | [Ω*m] | Das Volumen ist der räumliche Inhalt eines geometrischen Körpers |

| Abhebekraft | FA | [N] | |

| Abrieb | Der mechanisch bedingte Stoffverlust an Kontaktstücken | ||

| Prellen | Eine ein- oder mehrmalige Unterbrechung der Kontaktgabe während eines Schaltvorganges, hervorgerufen durch wechselweise Umwandlung von potentieller in kinetische Energie | ||

| Kontaktverschleiß | Umfasst alle Veränderungen der Kontaktoberfläche. Es ist zu unterscheiden zwischen elektrischem und mechanischem Verschleiß | ||

| Materialwanderung | Die bei Schaltvorgängen auftretende Übertragung von Kontaktmaterial von einem Kontaktstück auf das andere. Sie tritt hauptsächlich in Gleichstromkreisen auf. Die Wanderungsrichtung ist dabei abhängig von den Lastkreisparametern und den verwendeten Kontaktwerkstoffen | ||

| Abbrand | Der Stoffverlust an die Umgebung der Kontaktstelle, der infolge Lichtbogeneinwirkung entsteht. Er tritt sowohl beim Ein- als auch beim Ausschalten auf | ||

| Verschweißen | Tritt auf, wenn infolge hoher Strombelastung schmelzflüssige Berührungsflächen der Kontaktstücke aufeinandertreffen. Bei einschaltenden Kontaktstücken können Prelllichtbögen, bei geschlossenen Kontaktstücken ein zu hoher Kontaktwiderstand oder dynamisches Abheben der Kontaktstücke infolge hoher Kurzschlussströme Ursache für das Verschweißen der Kontaktstücke sein. Das Verschweißen führt dann zu einem Geräteausfall, wenn die Schweißverbindung nicht durch gerätespezifische Öffnungskräfte wieder getrennt werden kann | ||

| Lichtbogenwanderung | Tritt auf, wenn beim Ausschaltvorgang ein ausreichend hohes Magnetfeld vorhanden ist, das eine Kraft auf den Lichtbogen ausübt, die ihn von der Entstehungsstelle z.B. in eine Löschkammer ablenkt | ||

| Lichtbogenlöschung | Bedeutet den Strom zu Null werden zu lassen und die Lichtbogenstrecke vom leitenden in den nichtleitenden Zustand überzuführen. Die angewandten Löschprinzipien hängen hauptsächlich von Stromart, Stromstärke und Netzspannung ab | ||

| Wiederverfestigung einer Schaltstrecke | Nennt man bei öffnenden Kontaktstücken den Vorgang, bei dem das elektrisch leitende Plasma des Lichtbogens nach dem Stromnulldurchgang seine Leitfähigkeit verliert |

- Electrical contact

is a property which is generated through the touching of two electrically conducting surfaces.

- Contact part

is a metallic component which is designed to create or interrupt an electrical contact (is frequently replaced by the term “contact” if it is clearly understandable that a physical piece or item is meant).

- Contact area

is the whole area on a contact part that may be used for contacting.

- Apparent contact area As

is the part of the contact area on contact parts that can make physical contact during the touching of two contacts.

- Load bearing contact area At

is the part of the apparent contact area which is affected by the contact force. It is the sum of all microscopic actual touching points.

- Effective contact area Aw

is the part of the load bearing contact area through which current is flowing and therefore the sum of all current carrying touching areas (a-spots), Aw < At < As.

- Contour area An

is the contiguous area which includes all effective a-spots, Aw < An < As ; An ≠ At.

- Contact resistance Rk

is composed of the constriction resistance and the film resistance.

- Constriction resistance Re

is the incremental electrical resistance generated by the constriction of the currents paths in the touching area (a-spot).

- Film resistance Rf

is generated by a foreign matter layer, which for ex. is formed by a reaction of the contact material surface with the surrounding atmosphere (a surface film is a substance on the contact surface with different properties than those of the actual contact material).

- Path resistance Rd

is the total electrical resistance between reference points (usually the device terminals) which can be freely chosen but must be defined. It is the sum of the conductor resistance Rb and the contact resistance Rk.

- Contact force Fk

is the force that is exerted between the two contact parts in the closed position.

- Frictional wear

is the loss of material caused by mechanical wear between contact parts.

- Bounce

is the single or multiple interruption of conduction between contact parts during the make operation caused by alternating transformation of kinetic to potential energy.

- Contact wear

includes all changes on a contact surface. Mechanical and electrical wear must be distinguished.

- Material transfer

is the transfer of contact material from one contact part to the other. It occurs mainly during switching of DC loads. The direction of the transfer depends on the load circuit properties and the contact materials used.

- Arc erosion

is the loss of material into the surrounding of the contact spot which is generated by electrical arcing. It occurs during contact make as well as break operations.

- Contact welding

occurs when melt-liquefied touching areas of the contact parts come in contact with each other. The melting occurs during high current carrying through these areas. During make operations this occurs through bounce arcs, on closed contacts a too high contact resistance or dynamic separation of the contacts due to high short circuit currents can cause the welding of the contacts. The welding then may cause a device failure if the device specific opening forces cannot break the weld connection.

- Arc movement

happens when during the break operation a sufficiently high magnetic field is generated which exerts a force on the electrical arc which is then moved from the originating spot towards an arc chute (or arc splitting plates).

- Arc extinguishing

means the process of letting the current go to zero and transferring the arcing gap from a conducting to the non-conducting stage. Selecting the most effective extinguishing measures depend mostly on the current characteristics, the current value and the circuit voltage.

- Recovery

of an arc gap during contact opening is defined as the process of the electrically conducting plasma of an arc losing its electrical conductivity after reaching current-zero.

- Symbole used

Figure 1