Difference between revisions of "Werkstoffe auf Wolfram- und Molybdän-Basis"

Doduco Admin (talk | contribs) |

Teitscheid (talk | contribs) (temp edit) |

||

| (51 intermediate revisions by 2 users not shown) | |||

| Line 17: | Line 17: | ||

</figtable> | </figtable> | ||

| − | ===Silber-Wolfram Werkstoffe=== | + | ===Silber-Wolfram (SIWODUR)-Werkstoffe=== |

| − | Ag/W Kontaktwerkstoffe vereinigen in sich die hohe elektrische und | + | Ag/W (SIWODUR)-Kontaktwerkstoffe vereinigen in sich die hohe elektrische und |

thermische Leitfähigkeit des Silbers mit der hohen Abbrandfestigkeit des hochschmelzenden | thermische Leitfähigkeit des Silbers mit der hohen Abbrandfestigkeit des hochschmelzenden | ||

| − | Wolframs (<xr id="tab: | + | Wolframs (<xr id="tab:Physical Properties of-Contact Materials Based"/><!--(Table 2.36)-->). Die Herstellung der SIWODUR-Werkstoffe mit |

üblicherweise 50-80 Massen-% Wolfram erfolgt auf pulvermetallurgischem | üblicherweise 50-80 Massen-% Wolfram erfolgt auf pulvermetallurgischem | ||

Wege entweder durch Sintern mit flüssiger Phase oder über das Tränkverfahren. | Wege entweder durch Sintern mit flüssiger Phase oder über das Tränkverfahren. | ||

Kornform und Größe der Ausgangspulver bestimmen entscheidend das Gefüge | Kornform und Größe der Ausgangspulver bestimmen entscheidend das Gefüge | ||

| − | sowie die mechanischen und kontaktspezifischen Eigenschaften dieser Stoffgruppe (<xr id="fig:Micro structure of Ag W 25 75"/><!--(Fig. 2.134)--> | + | sowie die mechanischen und kontaktspezifischen Eigenschaften dieser Stoffgruppe (<xr id="fig:Micro structure of Ag W 25 75"/><!--(Fig. 2.134)--> und <xr id="fig:Micro structure of Ag WC 50 50"/><!--(Fig. 2.135)-->), <xr id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"/><!--(Table 2.37)-->. |

Bei häufigem betriebsmäßigem Schalten unter Lichtbogenbelastung bilden sich | Bei häufigem betriebsmäßigem Schalten unter Lichtbogenbelastung bilden sich | ||

| Line 30: | Line 30: | ||

und damit schlecht leitende Oberflächenschichten, die eine deutliche | und damit schlecht leitende Oberflächenschichten, die eine deutliche | ||

Erhöhung des Kontaktwiderstandes und dadurch bei Führung des Dauerstromes | Erhöhung des Kontaktwiderstandes und dadurch bei Führung des Dauerstromes | ||

| − | eine unzulässige Erwärmung zur Folge haben. Aus diesem Grunde wird Ag/W in vielen Schaltgeräten gepaart mit Ag | + | eine unzulässige Erwärmung zur Folge haben. Aus diesem Grunde wird Ag/W in vielen Schaltgeräten gepaart mit Ag/C-Kontaktstücken eingesetzt. |

Silber-Wolfram-Kontakte kommen als Einzelteile in Form nahezu beliebig | Silber-Wolfram-Kontakte kommen als Einzelteile in Form nahezu beliebig | ||

| Line 41: | Line 41: | ||

Ag/W-Werkstoffe werden vor allem als Abbrennkontakte in Leistungsschaltern | Ag/W-Werkstoffe werden vor allem als Abbrennkontakte in Leistungsschaltern | ||

großer Leistung sowie als Hauptkontakte in Leistungschaltern kleinerer und | großer Leistung sowie als Hauptkontakte in Leistungschaltern kleinerer und | ||

| − | mittlerer Leistung und in Schutzschaltern eingesetzt (<xr id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR) | + | mittlerer Leistung und in Schutzschaltern eingesetzt (<xr id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"/><!--(Table 2.38)-->). In Nord- und Südamerika |

kommen Silber-Wolfram-Kontakstücke in großen Stückzahlen in Leitungsschutzschaltern | kommen Silber-Wolfram-Kontakstücke in großen Stückzahlen in Leitungsschutzschaltern | ||

mit niedrigem und mittlerem Schaltvermögen für die Hausinstallation | mit niedrigem und mittlerem Schaltvermögen für die Hausinstallation | ||

sowie für die kommerzielle Stromverteilung zum Einsatz. | sowie für die kommerzielle Stromverteilung zum Einsatz. | ||

| − | < | + | ===Silber-Wolframkarbid (SIWODUR C)-Werkstoffe=== |

| − | < | + | This group of contact materials contains the typically 40-65 wt-% of the very hard and erosion wear resistant tungsten carbide and the high conductivity silver <xr id="fig:Micro structure of Ag WC 50 50"/><!--(Fig. 2.135)--> <xr id="tab:Physical Properties of-Contact Materials Based"/><!--(Table 2.36)-->. Compared to Ag/W the Ag/WC (SIWODUR C) materials exhibit a higher resistance against contact welding <xr id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"/><!--(Table 2.37)-->. The rise in contact resistance experienced with Ag/W is less pronounced in Ag/WC because during arcing a protective gas layer of CO is formed which limits the reaction of oxygen on the contact surface and therefore the formation of metal oxides. |

| − | + | Higher requirements on low temperature rise can be fulfilled by adding a small amount of graphite which however increases the arc erosion. Silver–tungsten carbide–graphite materials with for example 27 wt% WC and 3 wt% graphite or 16 wt% WC and 2 wt% graphite are manufactured using the single tip press-sinter-repress (PSR) process <xr id="fig:Micro structure of -Ag WC 27 C3"/><!--(Fig. 2.136)-->. | |

| − | + | ||

| − | + | The applications of Ag/WC contacts are similar to those for Ag/W <xr id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"/><!--(Table 2.38)-->. | |

| − | + | ||

| − | + | === Silver–Molybdenum (SILMODUR) Materials=== | |

| − | + | Ag/Mo materials with typically 50-70 wt% molybdenum are usually produced by the powder metallurgical infiltration process <xr id="fig:Micro structure of Ag Mo 35 65"/><!--(Fig. 2.137)--> <xr id="tab:Physical Properties of-Contact Materials Based"/><!--(Table 2.36)-->. Their contact properties are similar to those of Ag/W materials <xr id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"/><!--(Table 2.37)-->. Since the molybdenum oxide is thermally less stable than tungsten oxide the self-cleaning effect of Ag/Mo contact surface during arcing is more pronounced and the contact resistance remains lower than that of Ag/W. The arc erosion resistance of Ag/Mo however is lower than the one for Ag/W materials. The main applications for Ag/Mo contacts are in equipment protecting switching devices <xr id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"/><!--(Table 2.38)-->. | |

| − | + | ||

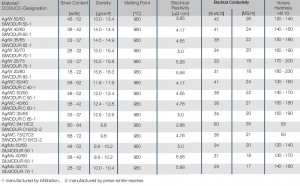

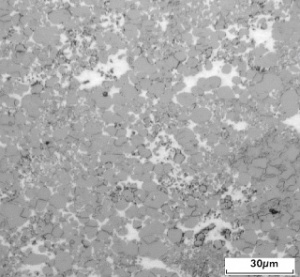

| − | + | <figtable id="tab:Physical Properties of-Contact Materials Based"> | |

| − | + | [[File:Physical Properties of-Contact Materials Based.jpg|right|thumb|Physical Properties of Contact Materials Based on Silver–Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | ||

| − | |||

</figtable> | </figtable> | ||

| + | <xr id="fig:Micro structure of Ag W 25 75"/><!--Fig. 2.134:--> Micro structure of Ag/W 25/75 | ||

| − | + | <xr id="fig:Micro structure of Ag WC 50 50"/><!--Fig. 2.135:--> Micro structure of Ag/WC 50/50 | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | Ag/WC | ||

| − | |||

| − | |||

| − | + | <xr id="fig:Micro structure of -Ag WC 27 C3"/><!--Fig. 2.136:--> Micro structure of Ag/WC27/C3 | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <xr id="fig:Micro structure of Ag Mo 35 65"/><!--Fig. 2.137:--> Micro structure of Ag/Mo 35/65 | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| Line 161: | Line 71: | ||

<figure id="fig:Micro structure of Ag W 25 75"> | <figure id="fig:Micro structure of Ag W 25 75"> | ||

| − | [[File:Micro structure of Ag W 25 75.jpg|left|thumb|<caption> | + | [[File:Micro structure of Ag W 25 75.jpg|left|thumb|<caption>Micro structure of Ag/W 25/75</caption>]] |

</figure> | </figure> | ||

<figure id="fig:Micro structure of Ag WC 50 50"> | <figure id="fig:Micro structure of Ag WC 50 50"> | ||

| − | [[File:Micro structure of Ag WC 50 50.jpg|left|thumb|<caption> | + | [[File:Micro structure of Ag WC 50 50.jpg|left|thumb|<caption>Micro structure of Ag/WC 50/50</caption>]] |

</figure> | </figure> | ||

<figure id="fig:Micro structure of -Ag WC 27 C3"> | <figure id="fig:Micro structure of -Ag WC 27 C3"> | ||

| − | [[File:Micro structure of -Ag WC 27 C3.jpg|left|thumb|<caption> | + | [[File:Micro structure of -Ag WC 27 C3.jpg|left|thumb|<caption>Micro structure of Ag/WC27/C3</caption>]] |

</figure> | </figure> | ||

<figure id="fig:Micro structure of Ag Mo 35 65"> | <figure id="fig:Micro structure of Ag Mo 35 65"> | ||

| − | [[File:Micro structure of Ag Mo 35 65.jpg|left|thumb|<caption> | + | [[File:Micro structure of Ag Mo 35 65.jpg|left|thumb|<caption>Micro structure of Ag/Mo 35/65</caption>]] |

</figure> | </figure> | ||

</div> | </div> | ||

<div class="clear"></div> | <div class="clear"></div> | ||

| − | <figtable id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR) | + | <figtable id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"> |

| − | <caption>'''<!--Table 2.37:--> | + | <caption>'''<!--Table 2.37:-->Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)'''</caption> |

<table class="twocolortable"> | <table class="twocolortable"> | ||

| − | <tr><th><p class="s12"> | + | <tr><th><p class="s12">Material/ DODUCO- Designation</p></th><th><p class="s12">Properties</p></th></tr><tr><td><p class="s12">Silver-Tungsten</p><p class="s12">SIWODUR</p><p class="s12">Silver-tungsten carbide SIWODUR C</p></td><td><p class="s12">Tendency to weld at high make currents in symmetrical pairing,</p><p class="s12">Higher contact resistance and higher temperature rise over increased number of operations through tungsten oxide and tungstate formation, especially for Ag/W,</p><p class="s12">High welding tendency of closed contacts during short circuit,</p><p class="s12">Very high arc erosion resistance, poor arc moving properties, High hardness and low formability,</p><p class="s12">Easy to braze and weld through Ag enriched backing layer</p></td></tr><tr><td><p class="s12">Silver-Tungsten Carbide plus Grafit SIWODUR C Plus</p></td><td><p class="s12">Low contact resistance and low temperature rise through graphite addition,</p><p class="s12">Lower tendency to contact welding, Lower arc erosion resistance than Ag/W</p></td></tr><tr><td><p class="s12">Silver-Molybdenum</p><p class="s12">SILMODUR</p></td><td><p class="s12">Better contact resistance stability due to less stable surface layers,</p><p class="s12">Lower arc erosion resistance than Ag/W</p></td></tr></table> |

</figtable> | </figtable> | ||

| − | <figtable id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR) | + | <figtable id="tab:Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)"> |

| − | <caption>'''<!--Table 2.38:--> | + | <caption>'''<!--Table 2.38:-->Contact and Switching Properties of Contact Materials Based on Silver – Tungsten (SIWODUR), Silver–Tungsten Carbide (SIWODUR C) and Silver Molybdenum (SILMODUR)'''</caption> |

{| class="twocolortable" style="text-align: left; font-size: 12px" | {| class="twocolortable" style="text-align: left; font-size: 12px" | ||

|- | |- | ||

| − | ! | + | !Material |

| − | ! | + | !Application Examples |

| − | ! | + | !Form of Supply |

|- | |- | ||

| − | |Ag/W<br /> | + | |Ag/W<br />SIWODUR |

| − | | | + | |Circuit breakers (not current limiting) |

| − | |rowspan="3" | | + | |rowspan="3" | Contact tips, brazed and welded<br />contact parts |

|- | |- | ||

| − | |Ag/W<br /><br />Ag/WC<br /><br />Ag/WC/C<br /> | + | |Ag/W<br />SIWODUR<br />Ag/WC<br />SIWODUR C<br />Ag/WC/C<br />SIWODUR C/C |

| − | | | + | |(Main) Power switches<br /> paired with Ag/C)<br /> |

| − | + | Fault current circuit breakers<br />(paired with Ag/C) | |

|- | |- | ||

| − | |Ag/Mo<br /> | + | |Ag/Mo<br />SILMODUR |

| − | | | + | |Device protection switches |

|} | |} | ||

</figtable> | </figtable> | ||

| − | === | + | === Copper–Tungsten (CUWODUR) Materials=== |

| − | + | Copper–tungsten (CUWODUR) materials with typically 50-85 wt% tungsten are produced by the infiltration process with the tungsten particle size selected according to the end application [[#figures4|(Figs. 5 – 8)]] <!--(Figs. 2.138 – 2.141)--> <xr id="tab:Physical Properties of Copper Tungsten CUWODUR Contact Materials"/><!--(Table 2.39)-->. To increase the wettability of the tungsten skeleton by copper a small amount of nickel < 1 wt% is added to the starting powder mix. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | + | W/Cu materials exhibit a very high arc erosion resistance <xr id="tab:Contact and Switching Properties of Copper–Tungsten (CUWODUR) Contact Materials"/><!--(Table 2.40)-->. Compared to silver–tungsten materials they are however less suitable to carry permanent current. |

| − | < | ||

| − | + | With a solid tungsten skeleton as it is the case for W/C infiltrated materials with 70-85 wt% tungsten the lower melting component copper melts and vaporizes in the intense electrical arc. At the boiling point of copper (2567°C) the still solid tungsten is efficiently “cooled” and remains pretty much unchanged. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | During very high thermal stress on the W/Cu contacts, for example during short circuit currents > 40 kA the tungsten skeleton requires special high mechanical strength. For such applications a high temperature sintering of tungsten from selected particle size powder is applied before the usual infiltration with copper (example: CUWODUR H). | |

| − | |||

| + | For high voltage load switches the most advantageous contact system consists of a contact tulip and a contact rod. Both contact assemblies are made usually from the mechanically strong and high conductive CuCrZr material and W/Cu as the arcing tips. The thermally and mechanically highly stressed attachment between the two components is often achieved by utilizing electron beam welding or capacitor discharge percussion welding. Other attachment methods include brazing and cast-on of copper followed by cold forming steps to increase hardness and strength. | ||

| − | + | The main application areas for CUWODUR materials are as arcing contacts in load and high power switching in medium and high voltage switchgear as well as electrodes for spark gaps and over voltage arresters <xr id="tab:Application Examples and Forms of Supply for Tungsten– Copper (CUWODUR) Contact Materials"/><!--(Table 2.41)-->. | |

| − | |||

| − | |||

| − | + | <figtable id="tab:Physical Properties of Copper Tungsten CUWODUR Contact Materials"> | |

| − | + | [[File:Physical Properties of Copper Tungsten CUWODUR Contact Materials.jpg|right|thumb|Physical Properties of Copper Tungsten (CUWODUR) Contact Materials]] | |

| − | + | </figtable> | |

| − | + | <div id="figures4"> | |

| − | + | <xr id="fig:Micro structure of W Cu 70 30 G"/><!--Fig. 2.139:--> Micro structure of W/Cu 70/30 G | |

| − | + | <xr id="fig:Micro structure of W Cu 70 30 H"/><!--Fig. 2.140:--> Micro structure of W/Cu 70/30 H | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <xr id="fig:Micro structure of W Cu 70 30 F"/><!--Fig. 2.138:--> Micro structure of W/Cu 70/30 F | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <xr id="fig:Micro structure of W Cu 80 20 H"/><!--Fig. 2.141:--> Micro structure of W/Cu 80/20 H | |

| − | + | </div> | |

| − | |||

<div class="multiple-images"> | <div class="multiple-images"> | ||

<figure id="fig:Micro structure of W Cu 70 30 G"> | <figure id="fig:Micro structure of W Cu 70 30 G"> | ||

| − | [[File:Micro structure of W Cu 70 30 G.jpg|left|thumb|<caption> | + | [[File:Micro structure of W Cu 70 30 G.jpg|left|thumb|<caption>Micro structure of W/Cu 70/30 G</caption>]] |

| + | </figure> | ||

| + | |||

| + | <figure id="fig:Micro structure of W Cu 70 30 H"> | ||

| + | [[File:Micro structure of W Cu 70 30 H.jpg|left|thumb|<caption>Micro structure of W/Cu 70/30 H</caption>]] | ||

</figure> | </figure> | ||

<figure id="fig:Micro structure of W Cu 70 30 F"> | <figure id="fig:Micro structure of W Cu 70 30 F"> | ||

| − | [[File:Micro structure of W Cu 70 30 F.jpg|left|thumb|<caption> | + | [[File:Micro structure of W Cu 70 30 F.jpg|left|thumb|<caption>Micro structure of W/Cu 70/30 F</caption>]] |

</figure> | </figure> | ||

| − | + | <figure id="fig:Micro structure of W Cu 80 20 H"> | |

| + | [[File:Micro structure of W Cu 80 20 H.jpg|left|thumb|<caption>Micro structure of W/Cu 80/20 H</caption>]] | ||

| + | </figure> | ||

</div> | </div> | ||

<div class="clear"></div> | <div class="clear"></div> | ||

| + | <figtable id="tab:Contact and Switching Properties of Copper–Tungsten (CUWODUR) Contact Materials"> | ||

| + | <caption>'''<!--Table 2.40:-->Contact and Switching Properties of Copper–Tungsten (CUWODUR) Contact Materials'''</caption> | ||

| + | <table class="twocolortable"> | ||

| + | <tr><th><p class="s12">Material/ DODUCO- Designation</p></th><th><p class="s12">Properties</p></th></tr><tr><td><p class="s12">W/Cu F</p><p class="s12">CUWODUR F</p></td><td><p class="s12">Very high arc erosion resistance,</p><p class="s12">Uniform erosion pattern after high operation frequency, Very high mechanical strength,</p><p class="s12">Highly resistant against thermal and mechanical shock</p></td></tr><tr><td><p class="s12">W/Cu G</p><p class="s12">CUWODUR G</p></td><td><p class="s12">Very high arc erosion resistance, Very high mechanical strength,</p><p class="s12">Highly resistant against thermal and mechanical shock.</p></td></tr><tr><td><p class="s12">W/Cu H</p><p class="s12">CUWODUR H</p></td><td><p class="s12">Very high arc erosion resistance, very high mechanical strength, Especially high resistance against thermal and mechanical shock.</p></td></tr></table> | ||

| + | </figtable> | ||

| + | |||

| + | |||

| + | <figtable id="tab:Application Examples and Forms of Supply for Tungsten– Copper (CUWODUR) Contact Materials"> | ||

| + | <caption>'''<!--Table 2.41:-->Application Examples and Forms of Supply for Tungsten– Copper (CUWODUR) Contact Materials'''</caption> | ||

| + | <table class="twocolortable"> | ||

| + | <tr><th><p class="s12">Material</p></th><th><p class="s12">Application Examples</p></th><th><p class="s12">Form of Supply</p></th></tr><tr><td><p class="s12">W/Cu F</p></td><td><p class="s12">Transformer tap changers,</p><p class="s12">Medium voltage circuit breakers</p></td><td><p class="s12">Contact tips, formed parts, brazed</p><p class="s12">and welded contact parts</p></td></tr><tr><td><p class="s12">W/Cu G</p></td><td><p class="s12">Overvoltage arresters with spark gap,</p><p class="s12">Medium voltage circuit breakers, Medium voltage power switches, High voltage power switches and circuit breakers</p></td><td><p class="s12">Contact tips, formed parts, brazed</p><p class="s12">and welded contact parts; Contact tulips, rods and tubes</p></td></tr><tr><td><p class="s12">W/Cu H</p></td><td><p class="s12">High voltage power switches and circuit</p><p class="s12">breakers for very high short circuit currents</p></td><td><p class="s12">Welded contact parts; Contact tulips,</p><p class="s12">rods</p></td></tr></table> | ||

| + | </figtable> | ||

==Referenzen== | ==Referenzen== | ||

Revision as of 11:14, 23 September 2014

Contents

Wolfram und Molybdän (reine Metalle)

Wolfram zeichnet sich durch eine Reihe vorteilhafter Eigenschaften, wie hoher Schmelz- und Siedepunkt, ausreichend hohe elektrische und thermische Leitfähigkeit, sehr hohe Härte und Dichte aus (Table 1). Es wird überwiegend in Form aufgelöteter Plättchen für solche Schaltaufgaben eingesetzt, die eine schnelle Schaltfolge, z.B. in Hupen für Kfz, verlangen.

Molybdän hat als Kontaktwerkstoff eine wesentlich geringere Bedeutung als Wolfram, da es gegen Oxidation weniger beständig ist. Beide Elemente werden in großem Maße als hochschmelzende Komponenten für Verbundwerkstoffe mit Silber bzw. Kupfer eingesetzt.

Werkstoff | Gefügezustand | Vickershärte HV 10 | Zugfestigkeit [MPa] |

|---|---|---|---|

Wolfram | schwach verformtes Gefüge (Drähte und Bleche > 1 mm Dicke) stark verformtes Gefüge (Drähte und Bleche <1 mm Dicke) rekristallisiertes Gefüge | 300 - 500 500 - 750 360 | 1000 - 1800 1500 - 5000 1000 - 1200 |

Molybdän | schwach verformtes Gefüge (Drähte und Bleche <1 mm Dicke) stark verformtes Gefüge (Drähte und Bleche <1 mm Dicke) rekristallisiertes Gefüge | 140 - 320 260 - 550 140 - 160 | 600 - 1100 800 - 2500 600 - 900 |

Silber-Wolfram (SIWODUR)-Werkstoffe

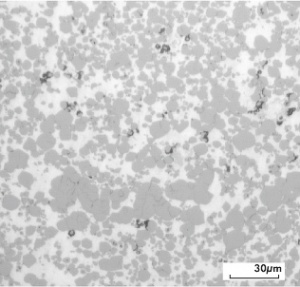

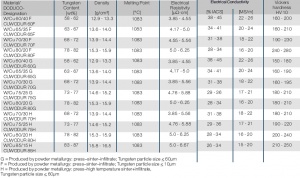

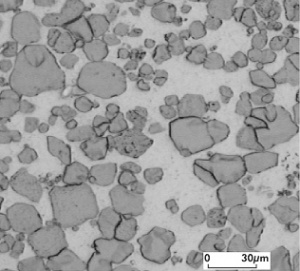

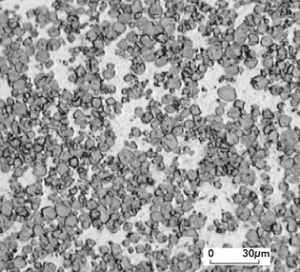

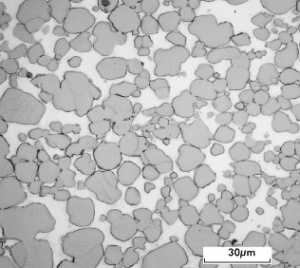

Ag/W (SIWODUR)-Kontaktwerkstoffe vereinigen in sich die hohe elektrische und thermische Leitfähigkeit des Silbers mit der hohen Abbrandfestigkeit des hochschmelzenden Wolframs (Table 2). Die Herstellung der SIWODUR-Werkstoffe mit üblicherweise 50-80 Massen-% Wolfram erfolgt auf pulvermetallurgischem Wege entweder durch Sintern mit flüssiger Phase oder über das Tränkverfahren. Kornform und Größe der Ausgangspulver bestimmen entscheidend das Gefüge sowie die mechanischen und kontaktspezifischen Eigenschaften dieser Stoffgruppe (Figure 1 und Figure 2), Table 4.

Bei häufigem betriebsmäßigem Schalten unter Lichtbogenbelastung bilden sich auf Ag/W-Kontaktoberflächen Wolframoxide sowie Mischoxide (Silber-Wolframate) und damit schlecht leitende Oberflächenschichten, die eine deutliche Erhöhung des Kontaktwiderstandes und dadurch bei Führung des Dauerstromes eine unzulässige Erwärmung zur Folge haben. Aus diesem Grunde wird Ag/W in vielen Schaltgeräten gepaart mit Ag/C-Kontaktstücken eingesetzt.

Silber-Wolfram-Kontakte kommen als Einzelteile in Form nahezu beliebig geformter Auflagen zum Einsatz. Zur besseren Weiterverarbeitung sind die Auflagen meist auf der Verbindungsseite mit Ag angereichert oder mit einer Lotauflage versehen. Die Verbindung der Ag/W-Teile mit Kontaktträgern erfolgt durch Löten, bei kleineren Abmessungen auch durch Widerstandsschweißen.

Ag/W-Werkstoffe werden vor allem als Abbrennkontakte in Leistungsschaltern großer Leistung sowie als Hauptkontakte in Leistungschaltern kleinerer und mittlerer Leistung und in Schutzschaltern eingesetzt (Table 4). In Nord- und Südamerika kommen Silber-Wolfram-Kontakstücke in großen Stückzahlen in Leitungsschutzschaltern mit niedrigem und mittlerem Schaltvermögen für die Hausinstallation sowie für die kommerzielle Stromverteilung zum Einsatz.

Silber-Wolframkarbid (SIWODUR C)-Werkstoffe

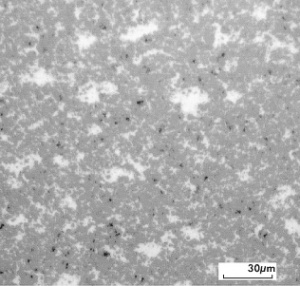

This group of contact materials contains the typically 40-65 wt-% of the very hard and erosion wear resistant tungsten carbide and the high conductivity silver Figure 2 Table 2. Compared to Ag/W the Ag/WC (SIWODUR C) materials exhibit a higher resistance against contact welding Table 4. The rise in contact resistance experienced with Ag/W is less pronounced in Ag/WC because during arcing a protective gas layer of CO is formed which limits the reaction of oxygen on the contact surface and therefore the formation of metal oxides.

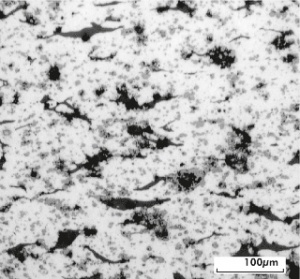

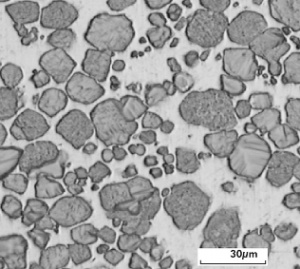

Higher requirements on low temperature rise can be fulfilled by adding a small amount of graphite which however increases the arc erosion. Silver–tungsten carbide–graphite materials with for example 27 wt% WC and 3 wt% graphite or 16 wt% WC and 2 wt% graphite are manufactured using the single tip press-sinter-repress (PSR) process Figure 3.

The applications of Ag/WC contacts are similar to those for Ag/W Table 4.

Silver–Molybdenum (SILMODUR) Materials

Ag/Mo materials with typically 50-70 wt% molybdenum are usually produced by the powder metallurgical infiltration process Figure 4 Table 2. Their contact properties are similar to those of Ag/W materials Table 4. Since the molybdenum oxide is thermally less stable than tungsten oxide the self-cleaning effect of Ag/Mo contact surface during arcing is more pronounced and the contact resistance remains lower than that of Ag/W. The arc erosion resistance of Ag/Mo however is lower than the one for Ag/W materials. The main applications for Ag/Mo contacts are in equipment protecting switching devices Table 4.

Figure 1 Micro structure of Ag/W 25/75

Figure 2 Micro structure of Ag/WC 50/50

Figure 3 Micro structure of Ag/WC27/C3

Figure 4 Micro structure of Ag/Mo 35/65

Material/ DODUCO- Designation | Properties |

|---|---|

Silver-Tungsten SIWODUR Silver-tungsten carbide SIWODUR C | Tendency to weld at high make currents in symmetrical pairing, Higher contact resistance and higher temperature rise over increased number of operations through tungsten oxide and tungstate formation, especially for Ag/W, High welding tendency of closed contacts during short circuit, Very high arc erosion resistance, poor arc moving properties, High hardness and low formability, Easy to braze and weld through Ag enriched backing layer |

Silver-Tungsten Carbide plus Grafit SIWODUR C Plus | Low contact resistance and low temperature rise through graphite addition, Lower tendency to contact welding, Lower arc erosion resistance than Ag/W |

Silver-Molybdenum SILMODUR | Better contact resistance stability due to less stable surface layers, Lower arc erosion resistance than Ag/W |

| Material | Application Examples | Form of Supply |

|---|---|---|

| Ag/W SIWODUR |

Circuit breakers (not current limiting) | Contact tips, brazed and welded contact parts |

| Ag/W SIWODUR Ag/WC SIWODUR C Ag/WC/C SIWODUR C/C |

(Main) Power switches paired with Ag/C) Fault current circuit breakers | |

| Ag/Mo SILMODUR |

Device protection switches |

Copper–Tungsten (CUWODUR) Materials

Copper–tungsten (CUWODUR) materials with typically 50-85 wt% tungsten are produced by the infiltration process with the tungsten particle size selected according to the end application (Figs. 5 – 8) Table 5. To increase the wettability of the tungsten skeleton by copper a small amount of nickel < 1 wt% is added to the starting powder mix.

W/Cu materials exhibit a very high arc erosion resistance Table 6. Compared to silver–tungsten materials they are however less suitable to carry permanent current.

With a solid tungsten skeleton as it is the case for W/C infiltrated materials with 70-85 wt% tungsten the lower melting component copper melts and vaporizes in the intense electrical arc. At the boiling point of copper (2567°C) the still solid tungsten is efficiently “cooled” and remains pretty much unchanged.

During very high thermal stress on the W/Cu contacts, for example during short circuit currents > 40 kA the tungsten skeleton requires special high mechanical strength. For such applications a high temperature sintering of tungsten from selected particle size powder is applied before the usual infiltration with copper (example: CUWODUR H).

For high voltage load switches the most advantageous contact system consists of a contact tulip and a contact rod. Both contact assemblies are made usually from the mechanically strong and high conductive CuCrZr material and W/Cu as the arcing tips. The thermally and mechanically highly stressed attachment between the two components is often achieved by utilizing electron beam welding or capacitor discharge percussion welding. Other attachment methods include brazing and cast-on of copper followed by cold forming steps to increase hardness and strength.

The main application areas for CUWODUR materials are as arcing contacts in load and high power switching in medium and high voltage switchgear as well as electrodes for spark gaps and over voltage arresters Table 7.

Figure 5 Micro structure of W/Cu 70/30 G

Figure 6 Micro structure of W/Cu 70/30 H

Figure 7 Micro structure of W/Cu 70/30 F

Figure 8 Micro structure of W/Cu 80/20 H

Material/ DODUCO- Designation | Properties |

|---|---|

W/Cu F CUWODUR F | Very high arc erosion resistance, Uniform erosion pattern after high operation frequency, Very high mechanical strength, Highly resistant against thermal and mechanical shock |

W/Cu G CUWODUR G | Very high arc erosion resistance, Very high mechanical strength, Highly resistant against thermal and mechanical shock. |

W/Cu H CUWODUR H | Very high arc erosion resistance, very high mechanical strength, Especially high resistance against thermal and mechanical shock. |

Material | Application Examples | Form of Supply |

|---|---|---|

W/Cu F | Transformer tap changers, Medium voltage circuit breakers | Contact tips, formed parts, brazed and welded contact parts |

W/Cu G | Overvoltage arresters with spark gap, Medium voltage circuit breakers, Medium voltage power switches, High voltage power switches and circuit breakers | Contact tips, formed parts, brazed and welded contact parts; Contact tulips, rods and tubes |

W/Cu H | High voltage power switches and circuit breakers for very high short circuit currents | Welded contact parts; Contact tulips, rods |