Difference between revisions of "Herstellung von Halbzeugen"

Doduco Admin (talk | contribs) (→Kontaktprofile) |

Teitscheid (talk | contribs) (temp edit) |

||

| (12 intermediate revisions by 2 users not shown) | |||

| Line 20: | Line 20: | ||

beschrieben werden. | beschrieben werden. | ||

| − | + | During ''hot cladding'', the classic process, the materials to be clad are assembled into a cladding package in block or plate form, heated to about | |

| − | + | 800°C and clad (or "welded") together under high pressure <xr id="fig:Hot_cladding_of_pre_materials"/><!--(Fig. 3.3)-->. At the interface between the two materials a non-separable bond is formed by either diffusion of the reaction partners or in liquid phase by forming a AgCu eutectic alloy when an additional brazing alloy foil is placed between the two materials. Further processing is done by rolling with required annealing steps between subsequent thickness reductions. The disadvantage of this process is the usually limited short length of final material strips. | |

| − | |||

| − | (<xr id="fig:Hot_cladding_of_pre_materials"/><!--(Fig. 3.3)--> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<figure id="fig:Hot_cladding_of_pre_materials"> | <figure id="fig:Hot_cladding_of_pre_materials"> | ||

| − | [[File:Hot cladding of pre-materials (schematisch).jpg|right|thumb| | + | [[File:Hot cladding of pre-materials (schematisch).jpg|right|thumb|Hot cladding of pre-materials (schematisch)]] |

</figure> | </figure> | ||

| + | In the ''Cold Roll-Cladding'' process the bond between the contact and carrier material is achieved by cold deformation of > 50% in one rolling pass <xr id="fig:Cold roll-cladding of semi-finished strips (schematic)"/><!-- (Fig. 3.4)-->. The high plastic deformation causes cold welding in the boundary layer between the two materials. To increase the quality and strength of the bond a subsequent diffusion annealing is performed in most cases. This process is most suitable for clad semi-finished strips with thin contact material layers (≥ 2 μm) and large strip length (> 100 m). | ||

| + | |||

<figure id="fig:Cold roll-cladding of semi-finished strips (schematic)"> | <figure id="fig:Cold roll-cladding of semi-finished strips (schematic)"> | ||

| − | [[File:Cold roll-cladding of semi-finished strips (schematic).jpg|right|thumb| | + | [[File:Cold roll-cladding of semi-finished strips (schematic).jpg|right|thumb|Cold roll-cladding of semi-finished strips (schematic)]] |

</figure> | </figure> | ||

| + | |||

| + | *Typical configurations of clad contact strips <xr id="fig:Typical configurations of clad contact strips"/> | ||

| + | |||

<figure id="fig:Typical configurations of clad contact strips"> | <figure id="fig:Typical configurations of clad contact strips"> | ||

| − | [[File:Typical configurations of clad contact strips.jpg|right|thumb| | + | [[File:Typical configurations of clad contact strips.jpg|right|thumb|Typical configurations of clad contact strips]] |

</figure> | </figure> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Contact materials <br />Ag, Ag-alloys., Ag/Ni (SINIDUR), in special cases also Ag/CdO (DODURIT CdO), Ag/SnO<sub>2</sub> (SISTADOX), Ag/ZnO (DODURIT ZnO)<br /> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | * | + | *Carrier materials |

| − | * | + | *Dimensions <xr id="fig:Dimensions"/> |

| − | + | <figure id="fig:Dimensions"> | |

| + | [[File:Dimensions.jpg|right|thumb|Dimensions]] | ||

| + | </figure> | ||

| + | When specifying the contact material layer thickness it is recommended to use the minimum required thickness. | ||

| − | * | + | *Quality criteria and tolerances |

| + | Strength properties and dimensional tolerances of clad contact bi-metals are derived from the standards DIN EN 1652 and DIN EN 1654 for Cu alloys. When specifying the width of the contact material layer it is recommended to use the minimum required value. All dimensions should be specified originating from one strip edge. | ||

| − | + | === Brazed Semi-Finished Contact Materials (Toplay–Profiles)=== | |

| + | The toplay process starts with a flat or profile – shaped contact material strip which is fed together with the wider non-precious carrier material and in most cases an intermediate thin foil of brazing alloy into a induction brazing machine <xr id="fig:Toplay brazing with an inductive heating inline equipment (schematic)"/><!--(Fig. 3.5)-->. An evenly distributed and reliable braze joint can be achieved this way between contact and carrier materials. The combined material strip is rather soft after the brazing process and re-hardened during a subsequent profile rolling step. In this way different shapes and configurations can easily be achieved. | ||

| − | |||

<figure id="fig:Toplay brazing with an inductive heating inline equipment (schematic)"> | <figure id="fig:Toplay brazing with an inductive heating inline equipment (schematic)"> | ||

| − | [[File:Toplay brazing with an inductive heating inline equipment (schematic).jpg|right|thumb| | + | [[File:Toplay brazing with an inductive heating inline equipment (schematic).jpg|right|thumb|Toplay brazing with an inductive heating inline equipment (schematic)]] |

</figure> | </figure> | ||

| + | |||

| + | *Typical configurations of toplay contact profiles <xr id="fig:Typical configurations of toplay contact profiles2"/> | ||

| + | |||

<figure id="fig:Typical configurations of toplay contact profiles2"> | <figure id="fig:Typical configurations of toplay contact profiles2"> | ||

| − | [[File:Typical configurations of toplay contact profiles2.jpg|right|thumb| | + | [[File:Typical configurations of toplay contact profiles2.jpg|right|thumb|Typical configurations of toplay contact profiles]] |

</figure> | </figure> | ||

| + | *Contact materials <br />Ag, AgNi 0,15 (ARGODUR), AgCu, AgCuNi (ARGODUR 27), Ag/Ni (SINIDUR), | ||

| + | Ag/CdO (DODURIT CdO), Ag/SnO<sub>2</sub> (SISTADOX), Ag/ZnO (DODURIT ZnO)<br /> | ||

| + | |||

| + | *Carrier materials <br />Cu, CuZn, CuSn et al.<br /> | ||

| + | |||

| + | *Quality criteria, dimensions and tolerances <xr id="fig:Quality criteria dimensions and tolerances"/> | ||

| + | |||

<figure id="fig:Quality criteria dimensions and tolerances"> | <figure id="fig:Quality criteria dimensions and tolerances"> | ||

| − | [[File:Quality criteria dimensions and tolerances.jpg|right|thumb| | + | [[File:Quality criteria dimensions and tolerances.jpg|right|thumb|Quality criteria dimensions and tolerances]] |

</figure> | </figure> | ||

| − | + | Strength properties and dimensional tolerances of toplay profiles are derived from the standards DIN EN 1652 and DIN EN 1654 for Cu alloys. | |

| − | |||

| − | === | + | === Seam–Welded Contact Strip Materials (FDR–Profiles)=== |

| − | + | Seam–welding is the process by which the contact material in the form of a solid wire, narrow clad strip, or profile is attached to the carrier strip by overlapping or continuous weld pulses between rolling electrodes <xr id="fig:Seam-welding process (schematic)"/><!--(Fig. 3.6)-->. The weld joint is created by simultaneous effects of heat and pressure. Except for the very small actual weld joint area the original hardness of the carrier strip is maintained because of the limited short time of the heat supply. Therefore also spring-hard base materials can be used without loss of their mechanical strength. The use of clad contact pre-materials and profiles allows to minimize the use of the costly precious metal component tailored to the need for optimum reliability over the expected electrical life of the contact components. | |

| − | + | ||

| − | + | *Typical configurations of seam–welded contact strips and stamped parts <xr id="fig:Typical configurations of seam-welded contact strips"/> | |

| − | + | <figure id="fig:Typical configurations of seam-welded contact strips"> | |

| + | [[File:Typical configurations of seam-welded contact strips.jpg|right|thumb|Typical configurations of seam-welded contact strips]] | ||

| + | </figure> | ||

| − | + | <figure id="fig:Seam-welding process (schematic)"> | |

| − | + | [[File:Seam-welding process (schematic).jpg|right|thumb|Seam-welding process (schematic)]] | |

| − | + | </figure> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Contact materials <br />Au-Alloys, Pd-Alloys, Ag, AgNi 0,15 (ARGODUR), AgCu, AgCuNi (ARGODUR 27), Ag/Ni (SINIDUR), Ag/CdO (DODURIT CdO), Ag/SnO<sub>2</sub> (SISTADOX), Ag/ZnO (DODURIT ZnO)<br /> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | * | + | *Carrier materials <br />Cu, CuSn, CuZn, CuNiZn, CuBe et al.<br /> |

| − | * | + | *Dimensions <xr id="fig:Contact Profiles Dimensions"/> |

| + | <figure id="fig:Contact Profiles Dimensions"> | ||

| + | [[File:Contact Profiles Dimensions.jpg|right|thumb|Contact Profiles Dimensions]] | ||

| + | </figure> | ||

| − | * | + | *Quality criteria and tolerances |

| + | Strength properties and dimensional tolerances of toplay profiles are derived from the standards DIN EN 1652 and DIN EN 1654 for Cu alloys.. | ||

| − | + | === Contact Profiles (Contact Weld Tapes)=== | |

| + | Contact profiles span a broad range of dimensions. Width and thickness are typically between 0.8 – 8.0 mm and 0.2 – 3.0 mm resp. Special configurations, often defined as miniature-profiles or even micro–profiles can have a width < 2.0 mm. | ||

| − | + | Miniature–profiles are mostly composed of a contact-bimetal material with the contact material being a precious metal alloy or composite material clad, welded or coated by electroplating or vacuum-deposition (sputtered) onto a weldable base material. Since these profiles are attached to carrier strip materials usually by segment– or seam– welding to the base materials, materials with good welding properties such as nickel, copper-nickel, copper-tin, as well as copper-nickel-zinc alloys are used. The bottom surface of the profiles usually has formed weld rails or similar patterns to ensure a solid continuous metallurgical weld joint between the profile and the contact carrier. | |

| − | + | Contact profiles in larger sizes are often used for switching devices in the low voltage technology. For these the contact layer mostly consists of arc erosion resistant materials such as silver–nickel, silver–metal oxides or the weld resistant silver– graphite. The brazable or weldable underside of the metal oxide or silver–graphite materials is usually pure silver with also quite often a thin layer of a phosphorous containing brazing alloy applied to aid the welding process. | |

| − | |||

| − | |||

| − | |||

| − | < | + | *Typical configurations of multi-layer contact profiles <xr id="fig:Typical configurations of multi-layer contact profiles"/> |

<figure id="fig:Typical configurations of multi-layer contact profiles"> | <figure id="fig:Typical configurations of multi-layer contact profiles"> | ||

| − | [[File:Typical configurations of multi-layer contact profiles.jpg|right|thumb| | + | [[File:Typical configurations of multi-layer contact profiles.jpg|right|thumb|Typical configurations of multi-layer contact profiles]] |

</figure> | </figure> | ||

| + | |||

| + | *Contact materials <br />Au-Alloys, Pd-Alloys, Ag-Alloys, Ag/Ni (SINIDUR), Ag/CdO (DODURIT CdO), Ag/SnO<sub>2</sub> (SISTADOX), Ag/ZnO (DODURIT ZnO)<br /> | ||

| + | |||

| + | *Carrier materials <br />(weldable substrate material for multi-layer materials) Cu, Ni, CuNiFe, CuNiZn, CuSn, CuNiSn, NiCuFe<br /> | ||

| + | |||

| + | *Brazing alloy <br />L-Ag15P<br /> | ||

| + | |||

| + | *Quality criteria <br />Beause of the variety of configurations of contact profiles usually the quality issues are separately agreed upon between the manufacturer and the user.<br /> | ||

| + | |||

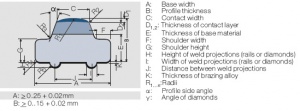

| + | *Dimensions and tolerances <xr id="fig:Contact Profiles Dimensions and tolerances"/> | ||

<figure id="fig:Contact Profiles Dimensions and tolerances"> | <figure id="fig:Contact Profiles Dimensions and tolerances"> | ||

| − | [[File:Contact Profiles Dimensions and tolerances.jpg|right|thumb| | + | [[File:Contact Profiles Dimensions and tolerances.jpg|right|thumb|Contact Profiles Dimensions and tolerances]] |

</figure> | </figure> | ||

| − | + | The thickness of the Au top-layer, which is sputtered for example, is between 0.2 and 5 μm, depending on the requirements. Tolerance of thickness is about ± 10%. | |

| − | |||

==Referenzen== | ==Referenzen== | ||

Revision as of 13:19, 21 September 2014

Halbzeuge für elektrische Kontakte können z.B. aus massivem Edelmetall, einer Edelmetalllegierung oder edelmetallhaltigen Verbundwerkstoffen bestehen. Sie werden als Drähte, Bänder oder Profile nach den bekannten Verfahren, wie Strangpressen und gegebenfalls anschließendem Glühen und Ziehen, hergestellt und nach werkseigenen Normen, die sich an die EN-Vorschriften für Kupfer-Halbzeuge anlehnen, geliefert. Große wirtschaftliche und technische Bedeutung haben Zwei- oder Mehrschichthalbzeuge, bei denen der Kontaktwerkstoff in fester Phase durch Plattieren, Löten und Schweißen oder durch Beschichtung aus flüssiger oder gasförmiger Phase auf das Trägermaterial aufgebracht wird.

Contents

Plattierte Halbzeuge (Kontaktbimetalle)

Plattierte Halbzeuge bestehen aus mindestens zwei Schichten verschiedener Metalle, dem Kontaktwerkstoff und dem Trägerwerkstoff, die stoffschlüssig miteinander verbunden sind. Entsprechend den jeweiligen elektrischen Anforderungen besteht der Kontaktwerkstoff meist aus Legierungen auf Gold-, Palladium- oder Silber-Basis, während als Trägerwerkstoff vor allem Kupfer- Legierungen zum Einsatz kommen. Für die Herstellung dieser Halbzeuge gibt es eine Reihe von Verfahren, von denen im folgenden die beiden wichtigsten beschrieben werden.

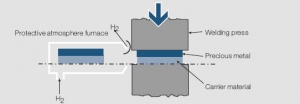

During hot cladding, the classic process, the materials to be clad are assembled into a cladding package in block or plate form, heated to about 800°C and clad (or "welded") together under high pressure Figure 1. At the interface between the two materials a non-separable bond is formed by either diffusion of the reaction partners or in liquid phase by forming a AgCu eutectic alloy when an additional brazing alloy foil is placed between the two materials. Further processing is done by rolling with required annealing steps between subsequent thickness reductions. The disadvantage of this process is the usually limited short length of final material strips.

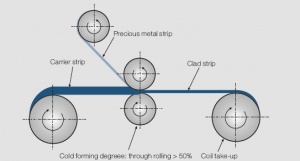

In the Cold Roll-Cladding process the bond between the contact and carrier material is achieved by cold deformation of > 50% in one rolling pass Figure 2. The high plastic deformation causes cold welding in the boundary layer between the two materials. To increase the quality and strength of the bond a subsequent diffusion annealing is performed in most cases. This process is most suitable for clad semi-finished strips with thin contact material layers (≥ 2 μm) and large strip length (> 100 m).

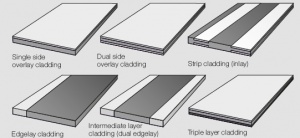

- Typical configurations of clad contact strips Figure 3

- Contact materials

Ag, Ag-alloys., Ag/Ni (SINIDUR), in special cases also Ag/CdO (DODURIT CdO), Ag/SnO2 (SISTADOX), Ag/ZnO (DODURIT ZnO)

- Carrier materials

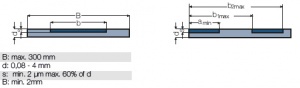

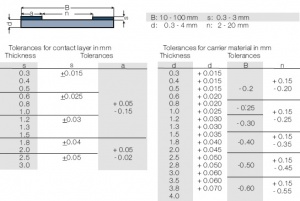

- Dimensions Figure 4

When specifying the contact material layer thickness it is recommended to use the minimum required thickness.

- Quality criteria and tolerances

Strength properties and dimensional tolerances of clad contact bi-metals are derived from the standards DIN EN 1652 and DIN EN 1654 for Cu alloys. When specifying the width of the contact material layer it is recommended to use the minimum required value. All dimensions should be specified originating from one strip edge.

Brazed Semi-Finished Contact Materials (Toplay–Profiles)

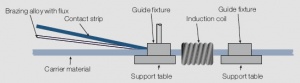

The toplay process starts with a flat or profile – shaped contact material strip which is fed together with the wider non-precious carrier material and in most cases an intermediate thin foil of brazing alloy into a induction brazing machine Figure 5. An evenly distributed and reliable braze joint can be achieved this way between contact and carrier materials. The combined material strip is rather soft after the brazing process and re-hardened during a subsequent profile rolling step. In this way different shapes and configurations can easily be achieved.

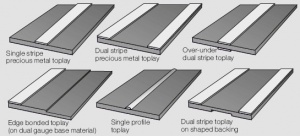

- Typical configurations of toplay contact profiles Figure 6

- Contact materials

Ag, AgNi 0,15 (ARGODUR), AgCu, AgCuNi (ARGODUR 27), Ag/Ni (SINIDUR),

Ag/CdO (DODURIT CdO), Ag/SnO2 (SISTADOX), Ag/ZnO (DODURIT ZnO)

- Carrier materials

Cu, CuZn, CuSn et al.

- Quality criteria, dimensions and tolerances Figure 7

Strength properties and dimensional tolerances of toplay profiles are derived from the standards DIN EN 1652 and DIN EN 1654 for Cu alloys.

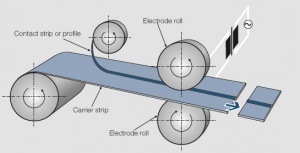

Seam–Welded Contact Strip Materials (FDR–Profiles)

Seam–welding is the process by which the contact material in the form of a solid wire, narrow clad strip, or profile is attached to the carrier strip by overlapping or continuous weld pulses between rolling electrodes Figure 9. The weld joint is created by simultaneous effects of heat and pressure. Except for the very small actual weld joint area the original hardness of the carrier strip is maintained because of the limited short time of the heat supply. Therefore also spring-hard base materials can be used without loss of their mechanical strength. The use of clad contact pre-materials and profiles allows to minimize the use of the costly precious metal component tailored to the need for optimum reliability over the expected electrical life of the contact components.

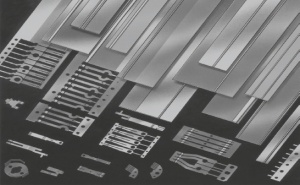

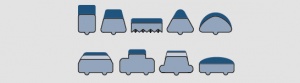

- Typical configurations of seam–welded contact strips and stamped parts Figure 8

- Contact materials

Au-Alloys, Pd-Alloys, Ag, AgNi 0,15 (ARGODUR), AgCu, AgCuNi (ARGODUR 27), Ag/Ni (SINIDUR), Ag/CdO (DODURIT CdO), Ag/SnO2 (SISTADOX), Ag/ZnO (DODURIT ZnO)

- Carrier materials

Cu, CuSn, CuZn, CuNiZn, CuBe et al.

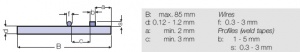

- Dimensions Figure 10

- Quality criteria and tolerances

Strength properties and dimensional tolerances of toplay profiles are derived from the standards DIN EN 1652 and DIN EN 1654 for Cu alloys..

Contact Profiles (Contact Weld Tapes)

Contact profiles span a broad range of dimensions. Width and thickness are typically between 0.8 – 8.0 mm and 0.2 – 3.0 mm resp. Special configurations, often defined as miniature-profiles or even micro–profiles can have a width < 2.0 mm.

Miniature–profiles are mostly composed of a contact-bimetal material with the contact material being a precious metal alloy or composite material clad, welded or coated by electroplating or vacuum-deposition (sputtered) onto a weldable base material. Since these profiles are attached to carrier strip materials usually by segment– or seam– welding to the base materials, materials with good welding properties such as nickel, copper-nickel, copper-tin, as well as copper-nickel-zinc alloys are used. The bottom surface of the profiles usually has formed weld rails or similar patterns to ensure a solid continuous metallurgical weld joint between the profile and the contact carrier.

Contact profiles in larger sizes are often used for switching devices in the low voltage technology. For these the contact layer mostly consists of arc erosion resistant materials such as silver–nickel, silver–metal oxides or the weld resistant silver– graphite. The brazable or weldable underside of the metal oxide or silver–graphite materials is usually pure silver with also quite often a thin layer of a phosphorous containing brazing alloy applied to aid the welding process.

- Typical configurations of multi-layer contact profiles Figure 11

- Contact materials

Au-Alloys, Pd-Alloys, Ag-Alloys, Ag/Ni (SINIDUR), Ag/CdO (DODURIT CdO), Ag/SnO2 (SISTADOX), Ag/ZnO (DODURIT ZnO)

- Carrier materials

(weldable substrate material for multi-layer materials) Cu, Ni, CuNiFe, CuNiZn, CuSn, CuNiSn, NiCuFe

- Brazing alloy

L-Ag15P

- Quality criteria

Beause of the variety of configurations of contact profiles usually the quality issues are separately agreed upon between the manufacturer and the user.

- Dimensions and tolerances Figure 12

The thickness of the Au top-layer, which is sputtered for example, is between 0.2 and 5 μm, depending on the requirements. Tolerance of thickness is about ± 10%.